Connection method for dissimilar metal welding test plates

A technology of dissimilar metals and connection methods, applied in welding/welding/cutting items, welding equipment, welding accessories, etc., can solve the problems of easy generation of hard and brittle phases, unavailability, welding cracks, etc., to achieve less melting, easy The effect of fast cooling of processing and welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

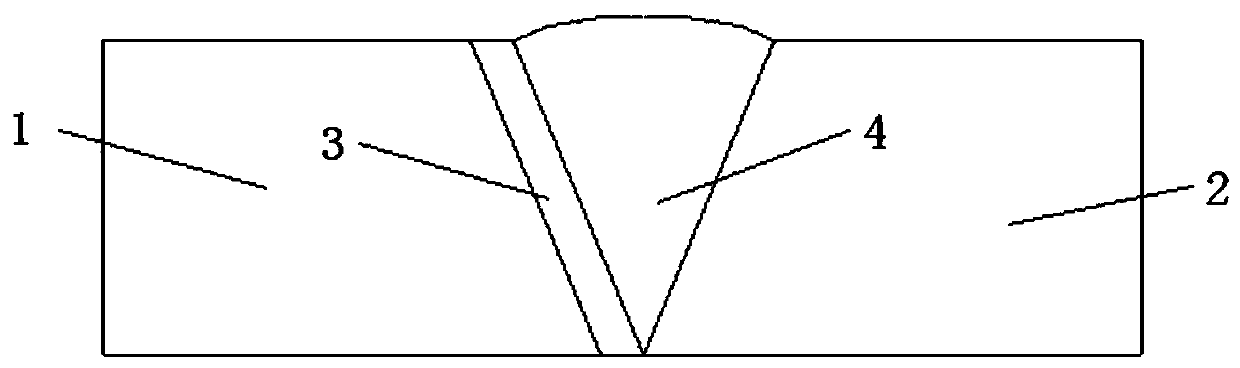

[0015] Such as figure 1 As shown, the material of the first welding test plate is 304, the size is 150×400mm, and the thickness is 10mm. The material of the second welding test plate is Q345, the size is 150×400mm, and the thickness is 10mm. The first type of welding test plate and the second type of welding test plate are butt-jointed with a V-shaped groove, the groove angle is 70°, and the blunt edge is 2 mm.

[0016] The laser cladding process was used to clad the groove surface of the first type of welding test plate with pure iron powder to form a transition layer weld 3 . The surface of the transition layer weld is parallel to the groove surface of the first type of welding test plate, with a thickness of 2mm. In order to ensure the quality of the transition layer weld, laser cladding needs to be protected by pure Ar. The specific welding parameters are show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com