Coating process for fully-degradable recyclable packaging material

A packaging material and coating process technology, which is applied in the field of fully degradable and recyclable packaging material coating process, can solve the problems affecting the full degradation and recycling of packaging materials, and achieve high tear resistance, high practicability, and improved The effect of overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

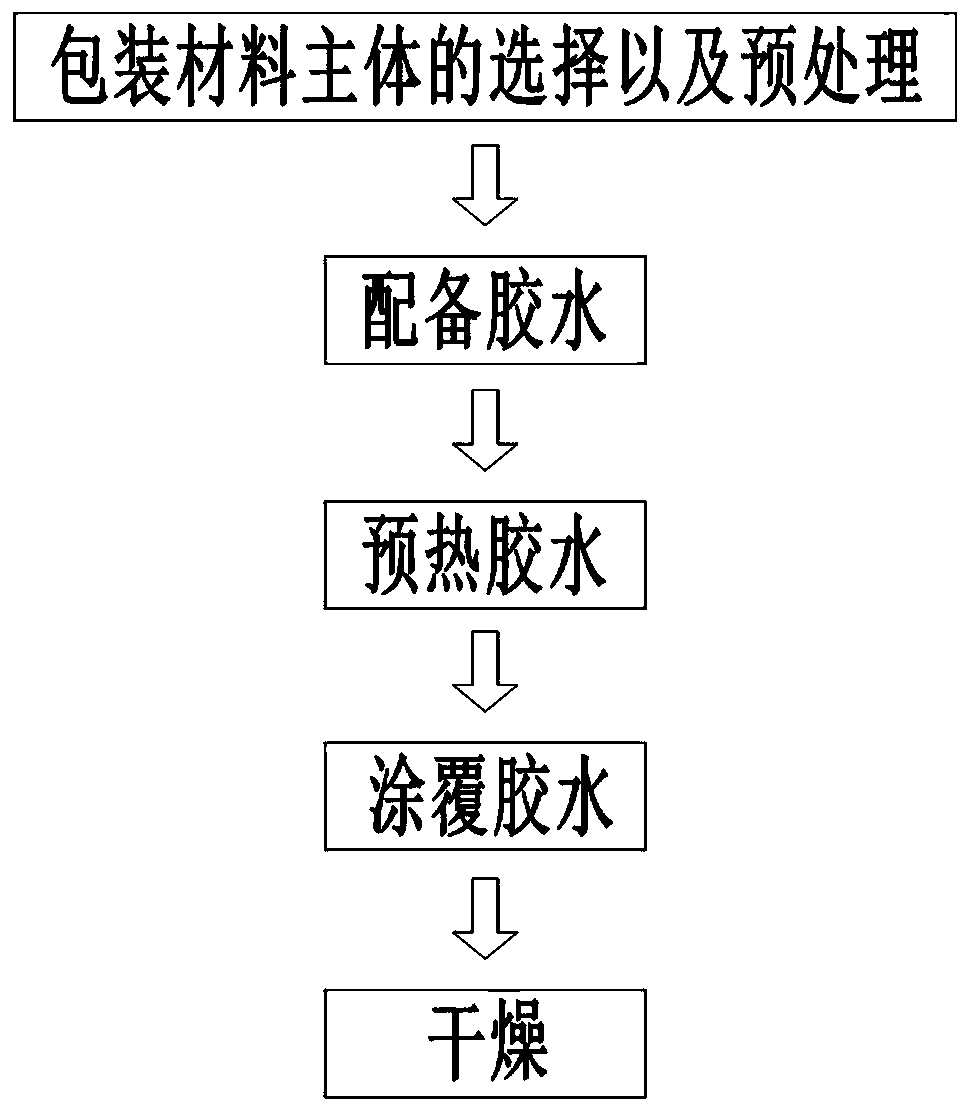

[0038] The fully degradable and recyclable packaging material coating process in this embodiment, such as figure 1 shown, including the following steps:

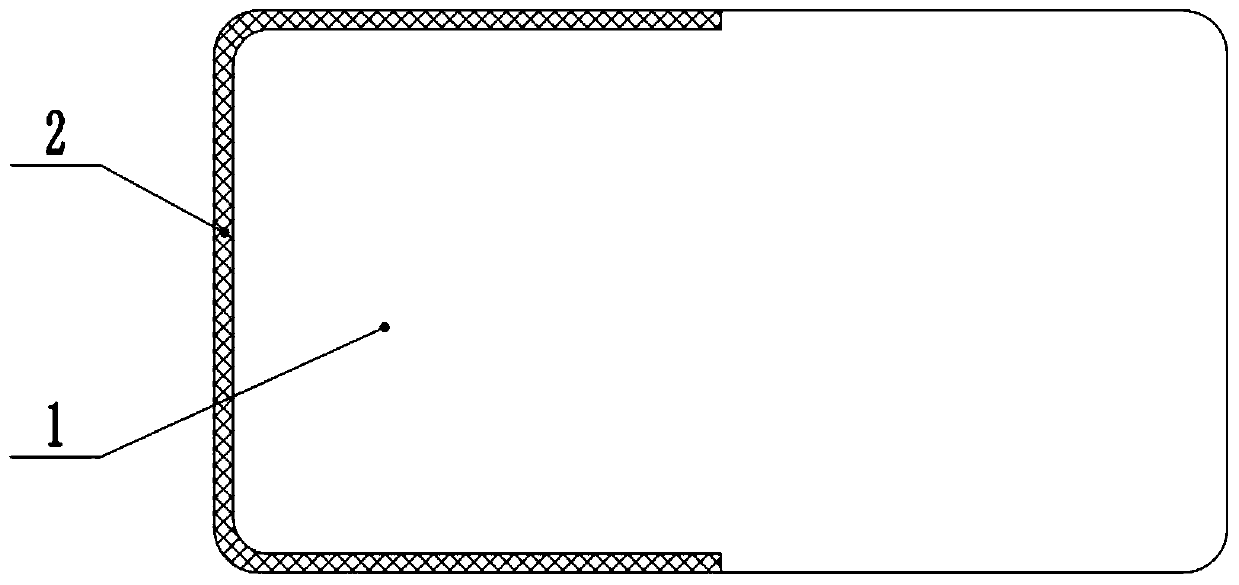

[0039] S1. Selection and pretreatment of the main body of packaging materials: such as figure 2 As shown, the fully degradable paper 1 is selected as the main body of the packaging material, and the powder removal and static elimination processes are performed on the fully degradable paper 1 .

[0040] S2, equipped with glue: Stir and mix dehydration malic acid resin, dammar resin, acrylic emulsion and water, the mass ratio of dehydration malic acid resin to dammar resin and acrylic emulsion is 2:1:2, and the solid content of the glue is 45%.

[0041] S3. Preheating the glue: heat the glue prepared in step S2 to 70-80°C and keep it warm. The temperature of the glue in this embodiment is 80°C.

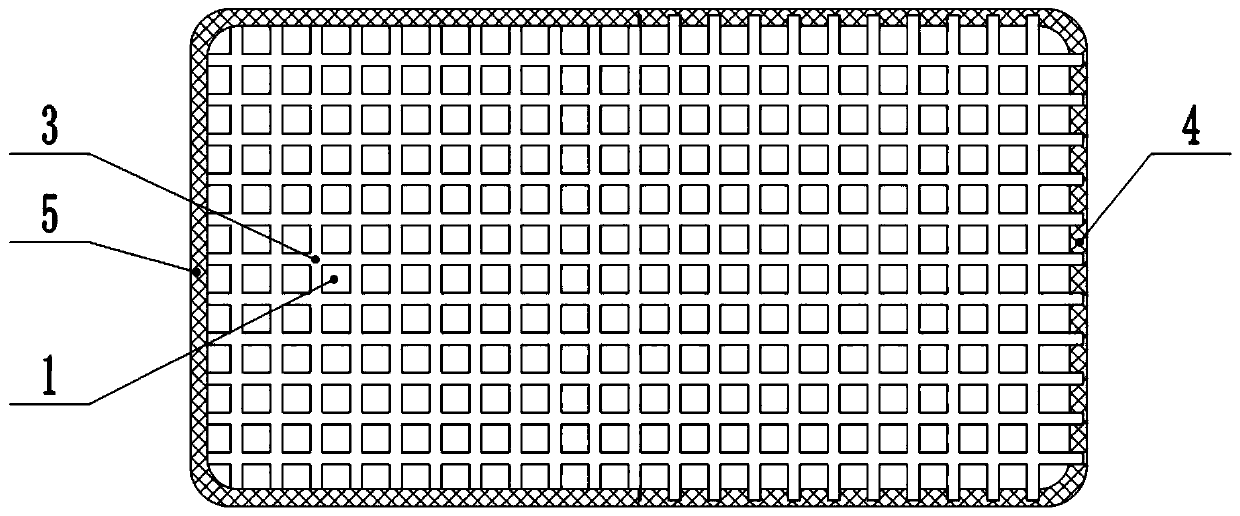

[0042] S4. Coating glue: On the surface of the fully degradable paper 1 selected in step S1, evenly coat the glue in step S3, an...

Embodiment 2

[0046] The difference between this example and Example 1 is that the mass ratio of the dehydrated malic acid resin to the dammar resin and the acrylic emulsion is 1.9:1:1.9, and the solid content of the glue is 44%.

Embodiment 3

[0048] The difference between this example and Example 1 is that the mass ratio of the dehydrated malic acid resin to the dammar resin and the acrylic emulsion is 2.1:1:2.1, and the solid content of the glue is 46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com