Water-based pre-coating detection agent, detection pen and detection method for digital printing

A technology of digital printing and detection agent, which can be used in measurement devices, mechanical devices, and material analysis by observing the impact on chemical indicators, which can solve problems such as insufficient bonding fastness, loss of printing materials, and increased production costs. Achieve the effect of eliminating coating quality problems, reducing the loss of printing materials and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A water-based precoating detection agent for digital printing, its composition and mass percentage are:

[0047] (1) Bromocresol purple: 1.5%;

[0048] (2) Deionized water: 12.5%;

[0049] (3) Ethanol with a purity of 95%: 85.7%;

[0050] (4) NaOH: 0.3%.

[0051] And configured through the following preparation steps:

[0052] S01. 1.5g of bromocresol violet was added to a beaker containing 85.7g of 95% ethanol solution with a purity of 85.7g, and manually stirred with a glass rod until the bromocresol violet was fully dissolved and uniformly dispersed to obtain bromocresol violet ethanol solution;

[0053] S02. The NaOH of 0.3g is added in the beaker that 12.5g deionized water is housed, fully dissolves with glass rod manual stirring, disperses evenly, obtains NaOH solution;

[0054] S03. Add the NaOH solution into the beaker containing the bromocresol purple ethanol solution, stir and disperse evenly with a glass rod, and obtain a green detection agent under natur...

Embodiment 2

[0068] Such as figure 1 and Figure 4 As shown, in this embodiment, the formula of the detection agent used is consistent with that of Embodiment 1, the difference is that the printing material used is a single white cardboard 7, and the coating equipment used is a single coating equipment, so the detection step It is also different, including the following steps:

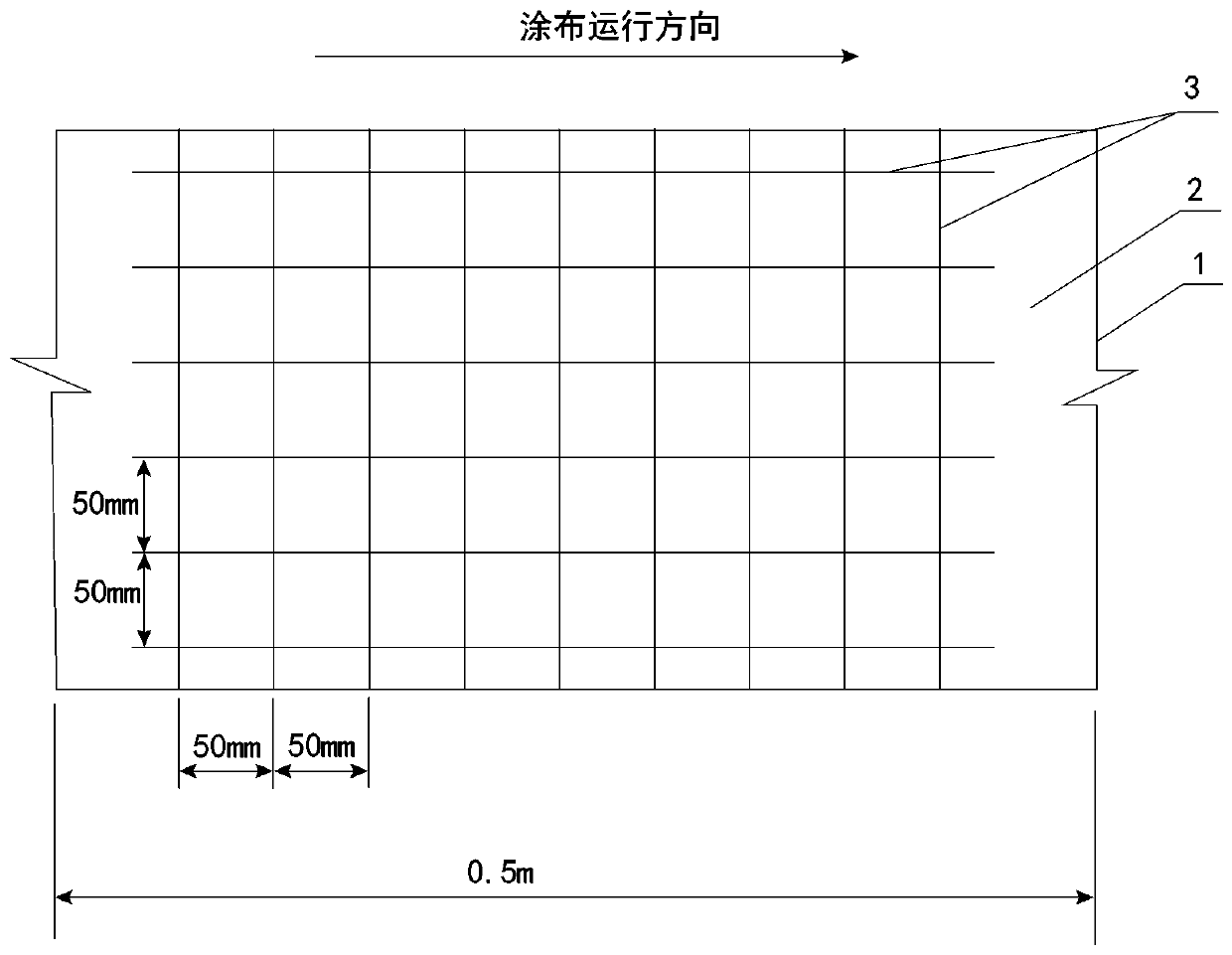

[0069] S1. Prepare the test sample: use the single-sheet coating equipment to uniformly apply a layer of digital printing water-based coating solution on the surface of the single-sheet white cardboard 7 according to the normal coating production process, and dry it with hot air on the single-sheet white cardboard A precoat 2 is formed on the surface of the paper 7;

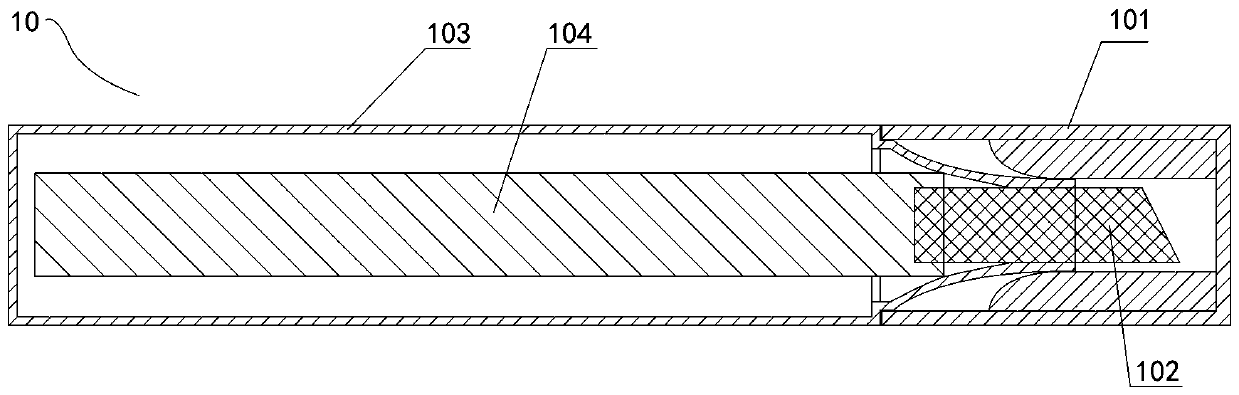

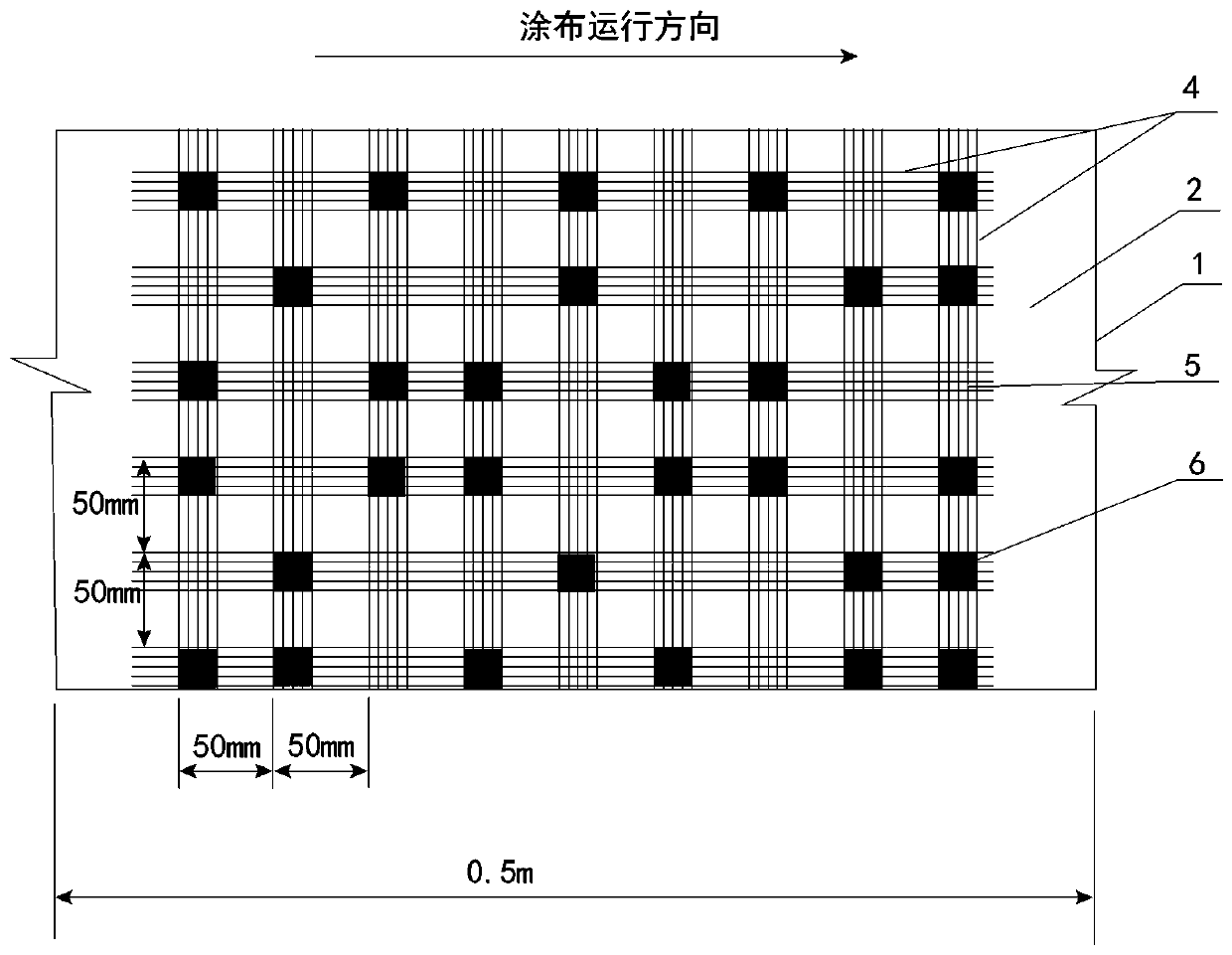

[0070] S2. Scratch detection agent: use the nib 102 of the detection pen 10 to pre-coat the single sheet of white cardboard 7 formed with the pre-coat 2 in the S1 step along the coating running direction and the direction perpendicular to the coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com