Lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and batteries, which is applied in the field of lithium-ion batteries, can solve problems such as battery performance deterioration, increased production costs, and wall rupture, achieving both safety and electrical performance, and the effect of controlling manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

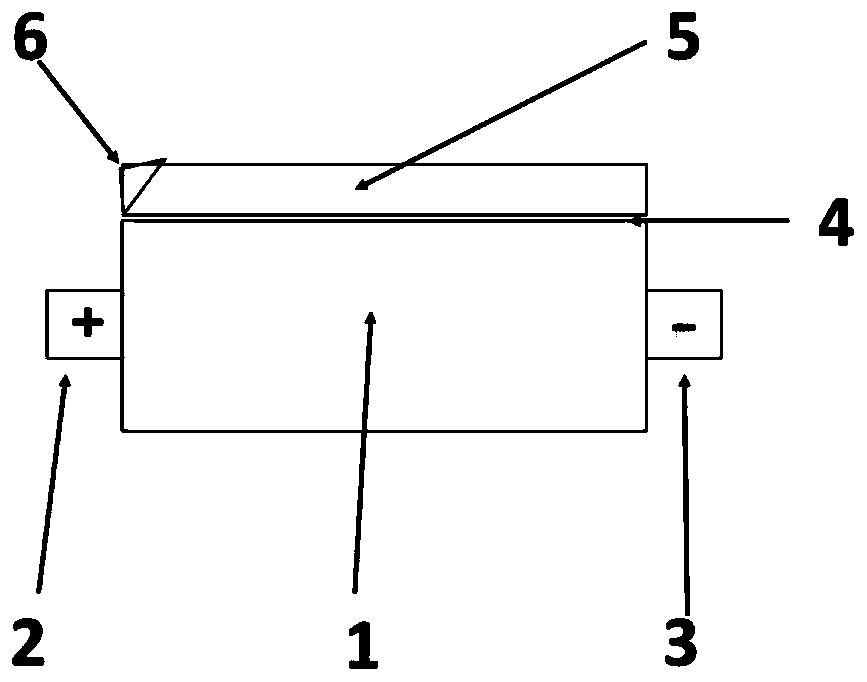

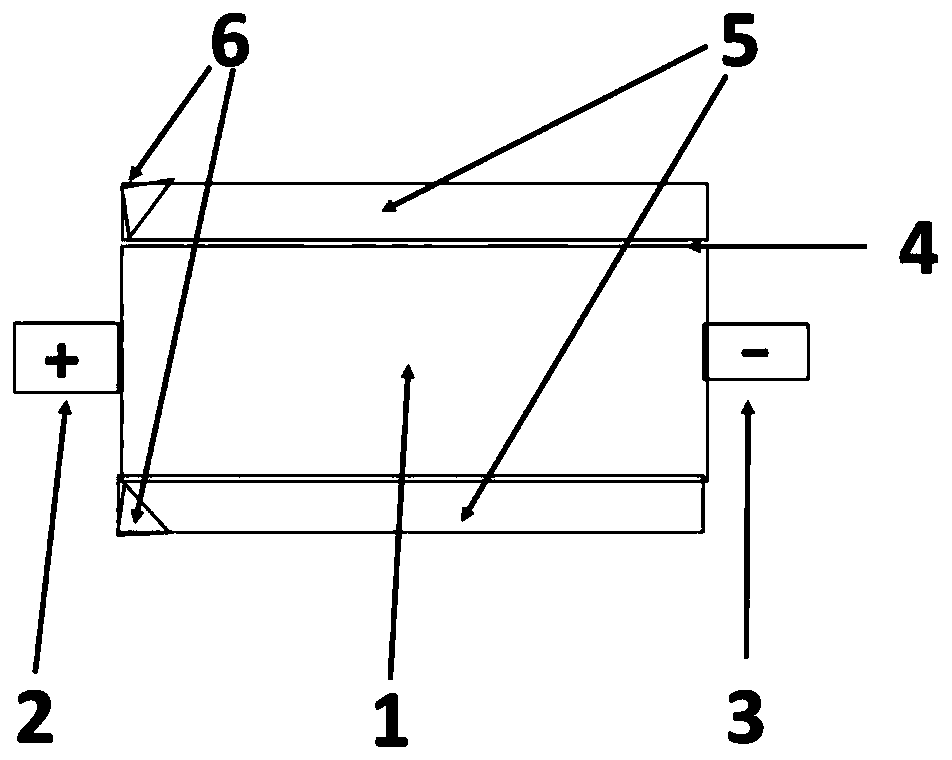

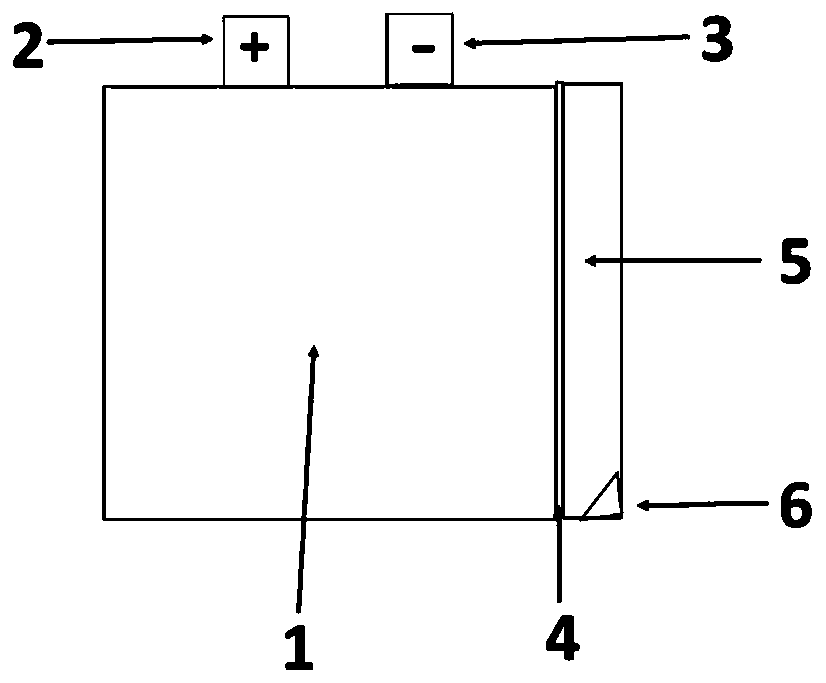

Image

Examples

preparation example Construction

[0030] The preparation process of lithium-ion batteries mainly includes the preparation of pole pieces, preparation of batteries, packaging, liquid injection, chemical formation and other processes. After the positive and negative electrodes are prepared, the positive electrode, negative electrode and separator are laminated or wound to make a bare cell (cell body), and then the cell body is packaged with aluminum-plastic film and other packaging films. Then inject the electrolyte into the packaged cell body. After the lithium-ion battery is packaged, an air bag will be set on one side of the cell body, and the air bag is connected to the cell body. When injecting liquid, the electrolyte is injected into the cell body from the opening of the air bag. After the liquid injection is completed, a certain amount of gas will be generated inside the cell body during the formation process, and the gas will enter the air bag. The existing lithium-ion battery preparation process will p...

Embodiment 1

[0036] The preparation method of the lithium-ion battery of the present embodiment comprises the following steps:

[0037] Preparation of positive electrode sheet: use ternary nickel-cobalt-manganese NCM111 as the positive electrode active material, disperse the positive electrode active material, binder (PVDF) and conductive agent (conductive carbon black) in N-methylpyrrolidone, and prepare a uniform positive electrode slurry The content of each solid material in the positive electrode slurry is as follows: NCM111 is 96wt%, PVDF is 2wt%, and conductive carbon black is 2wt%; the positive electrode slurry is evenly coated on both sides of the aluminum foil, and dried at 90 to 130°C for 6 Hours later, compact with a roller press to obtain the positive electrode sheet;

[0038] Prepare the negative electrode sheet: use graphite as the negative electrode active material, mix and disperse the negative electrode active material and binder (styrene-butadiene rubber), thickener (sodi...

Embodiment 2

[0045] The difference between this example and Example 1 is that: NCM523 is used as the positive electrode active material, and the rest of the steps and parameters are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com