Pure electric drive crawler-type field fresh tobacco leaf carrying machine

A pure electric drive, crawler technology, applied to tracked vehicles, electric power devices, motor vehicles, etc., can solve the problems of large undulating slopes, hidden dangers of soil pollution, narrow ridge spacing, etc., and achieve strong climbing ability and equipment Simple structure, stable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

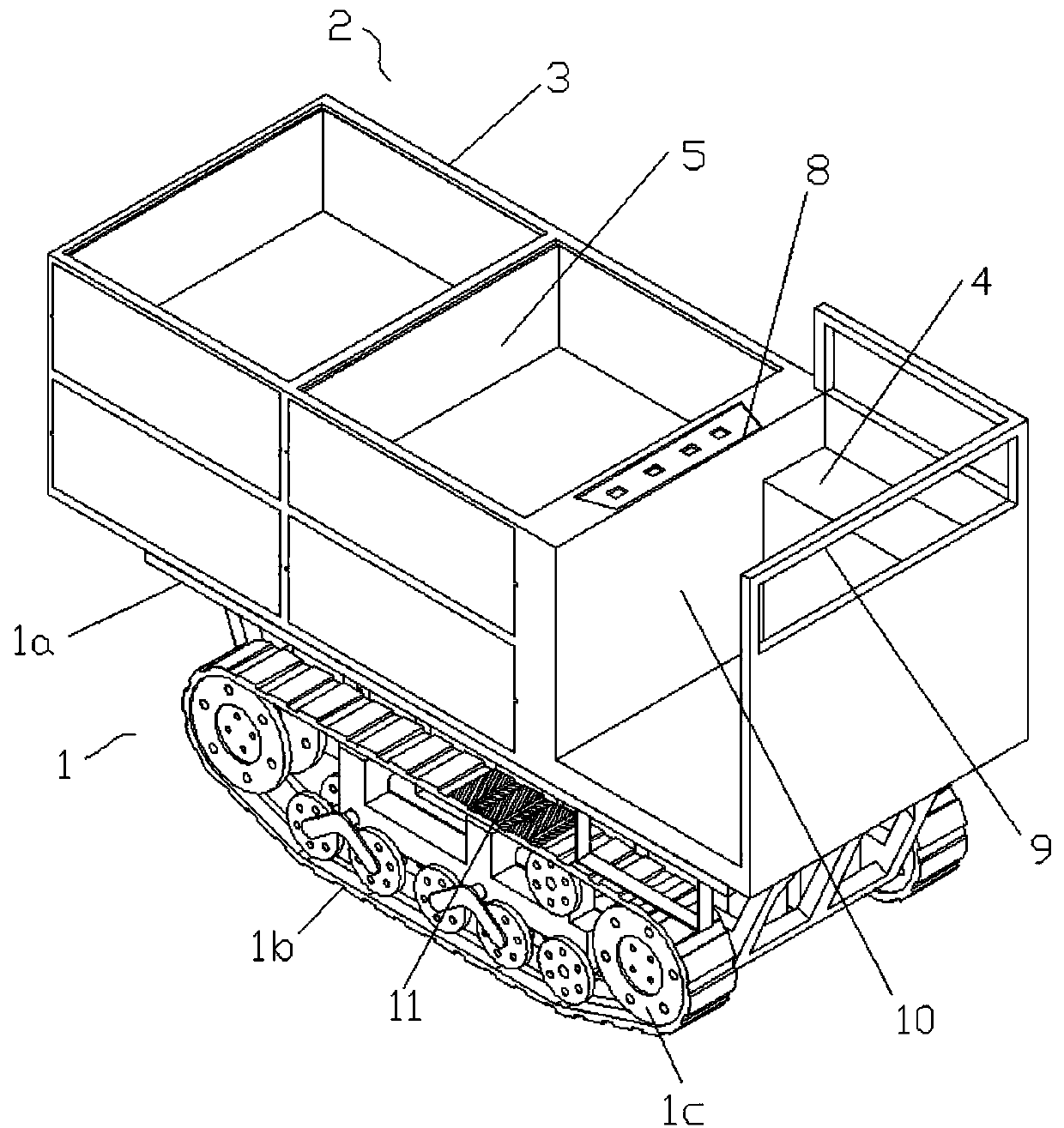

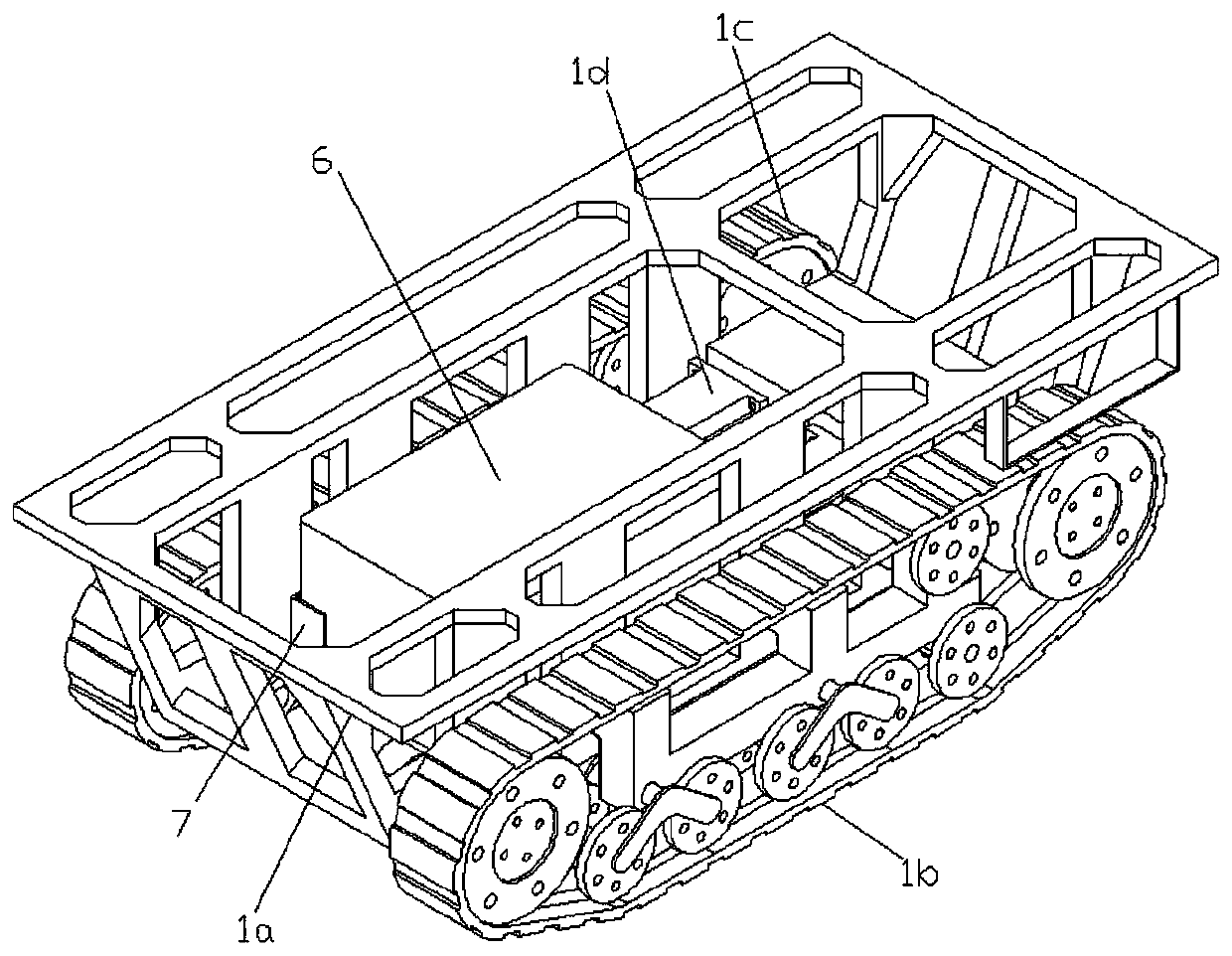

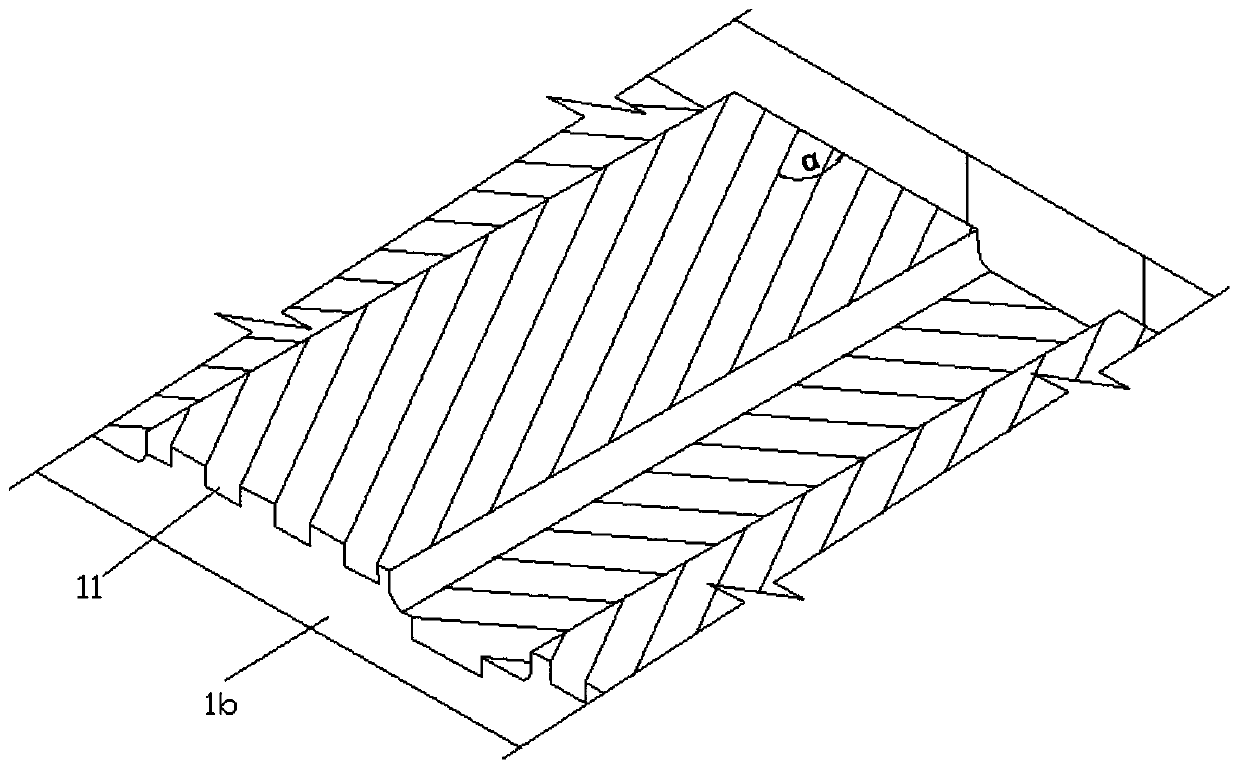

[0028] Example. A pure electric drive crawler-type fresh tobacco leaf transporter in the field, which is composed of Figure 1-Figure 3 As shown, it includes a chassis assembly 1, a vehicle frame 2 is arranged on the chassis assembly 1, and the vehicle frame 2 is respectively provided with a cigarette frame storage rack 3 and a control room 10 along the moving direction; the control room 10 is provided with a control seat 4, and the smoke A smoke frame 5 is movable in the frame storage frame 3; the chassis assembly 1 includes a chassis main frame 1a, the upper part of the chassis main frame 1a is connected with the vehicle frame 2, and crawler belts 1b are respectively provided on both sides of the lower side, and the two crawler belts 1b are respectively passed through The driving wheel 1c is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com