Fermentation production apparatus for edible fungus fermented food

A technology for fermented food and production equipment, applied in the field of food fermentation equipment, can solve the problems of small contact area, affect quality, low fermentation efficiency, etc., and achieve the effects of increasing contact area, improving fermentation degree, and improving fermentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

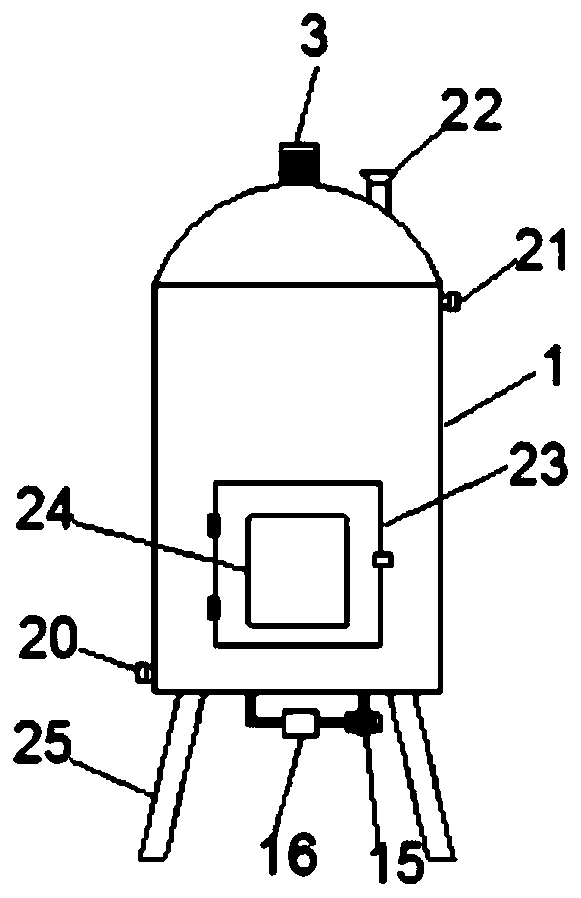

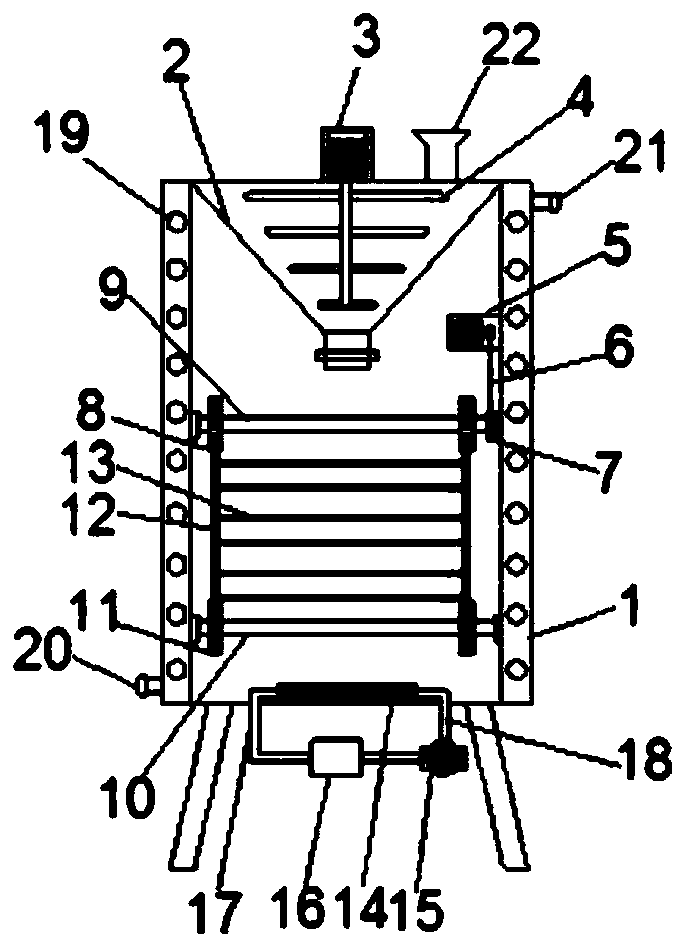

[0044] Such as Figure 1-4 As shown, a fermentation production device for edible mushroom fermented food includes a housing 1, a stirring bucket 2, and a layered fermentation mechanism; the mixing bucket 2 is arranged above the inside of the housing 1, and the top of the housing 1 is provided with A motor 3, the output shaft of the first motor 3 runs through the housing 1 and is connected with the stirring teeth 4, the first motor 3 drives the stirring teeth 4 to stir, and the bottom of the stirring bucket 2 is provided with a feeding port; the bottom of the stirring bucket 2 A layered fermentation mechanism is provided; the side wall of the housing 1 is provided with a dodge door 23, the dodge door 23 is hingedly connected with the housing 1, and the dodge door 23 is provided with a transparent observation window 24; the dodge door 23 and the housing 1 is sealed and connected by a sealing strip; the housing 1 has a double-layer structure, and a water bath heating system is pr...

Embodiment 2

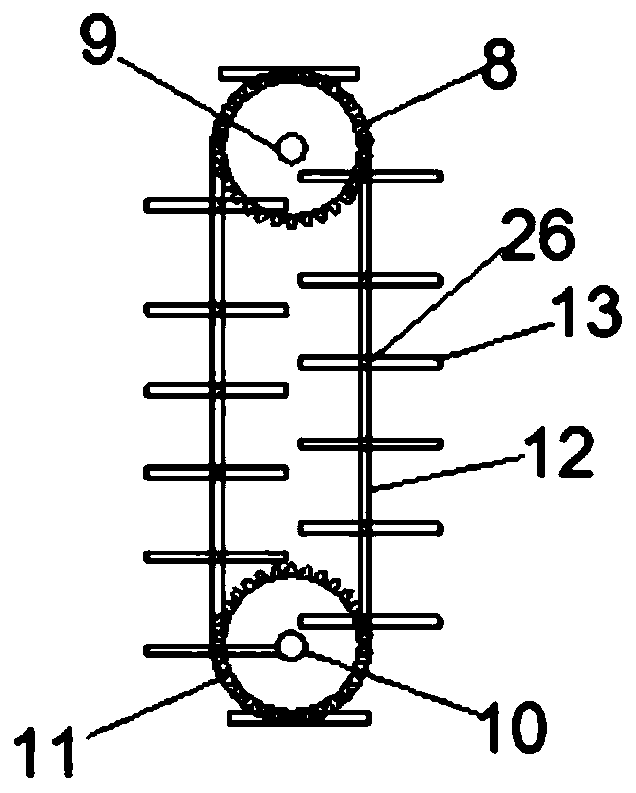

[0048] On the basis of Embodiment 1, the layered fermentation mechanism includes a second motor 5, the second motor 5 is connected to the housing 1, the output shaft of the second motor 5 is connected with a pulley 7, and the pulley 7 A belt 6 is matched and connected, and the other end of the belt 6 is connected with a driving shaft 9 through a pulley 7, and the two ends of the driving shaft 9 are rotationally connected with the housing 1 through bearings; the driving shaft 9 is provided with driving wheels near both ends. Disk 8.

[0049] A driven shaft 10 is provided below the driving shaft 9, and the two ends of the driven shaft 10 are rotationally connected with the housing 1 through provided bearings; the positions close to both ends of the driven shaft 10 are provided with driven wheels 11: Two transmission chains 12 are arranged symmetrically between the driving pulley 8 and the driven pulley 11 .

[0050] The two transmission chains 12 are provided with a plurality o...

Embodiment 3

[0053] On the basis of Example 1, in order to fully mix food and edible fungi, and further improve the degree of fermentation and fermentation quality, the length L of the stirring teeth 4 ranges from 23 to 60 cm; the distance between the volume V of the stirring bucket 2 and the diagonal line V / L is greater than or equal to 37 and less than or equal to 98; in order to further improve the fermentation rate and fermentation effect, the value range of the speed n1 of the first motor 3 is 1500-3500rpm; the value range of the speed n2 of the second motor 5 is 500-1500rpm , the diameter L of the stirring tooth 4, the volume V, n1, n2 of the stirring bucket 2, and the running time t satisfy the following relationship:

[0054] L=α·(n1 / Vt+n2 / Vt)1 / 2;

[0055] In the above formula, α is the value range of the relationship factor 0.646-7.253; the unit of L is centimeter; the unit of n1 and n2 is rpm, the unit of V is cm3; the unit of t is second.

[0056] The outer side of the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com