Heat treatment process of alloy spring steel

A spring steel and alloy technology, applied in the field of heat treatment, can solve the problems of easy occurrence of micro-cracks, reduce the surface hardness of spring steel billets, stress concentration, etc., and achieve the effects of good comprehensive mechanical properties, reduction of quenching stress, and reduction of deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

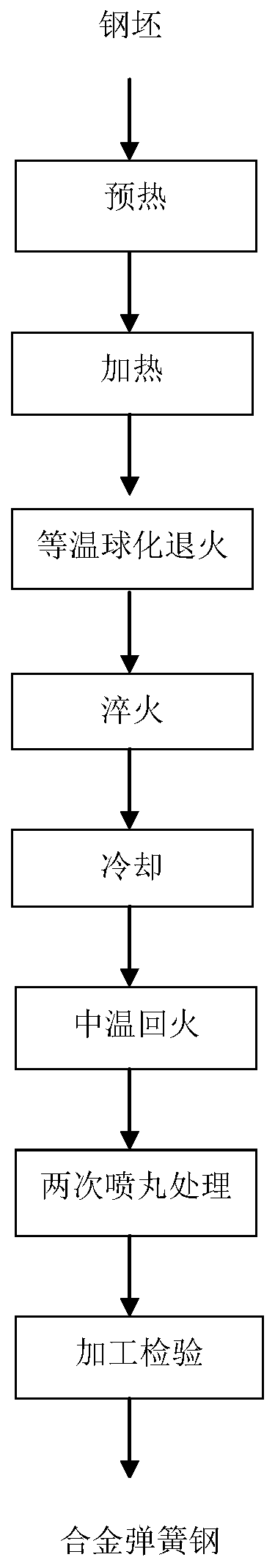

[0029] The invention provides a heat treatment process for alloy spring steel, which includes preheating, heating, isothermal spheroidizing annealing, quenching, cooling, medium temperature tempering, two shot peening treatments and processing inspection for a billet, specifically including the following steps:

[0030] (1) The alloy spring steel billet used in the preheating section is 50CrVA or other steel billets containing Cr and V.

[0031] (2) The temperature in the preheating section is controlled at 670°C and kept for 20 minutes;

[0032] (3) Heating the steel slab to 800°C in a tube furnace or resistance furnace and keeping it warm for 30 minutes. Nitrogen gas is introduced during the process. The flow rate of nitrogen gas is 4L / h to reduce the decarburization of the steel surface and ensure the service life of the steel;

[0033] (4) cooling the billet to 650°C at a cooling rate of 100°C / h, and then performing isothermal spheroidizing annealing at 650°C for 2.5 hours...

Embodiment 2

[0040] The invention provides a heat treatment process for alloy spring steel, which includes preheating, heating, isothermal spheroidizing annealing, quenching, cooling, medium temperature tempering, two shot peening treatments and processing inspection for a billet, specifically including the following steps:

[0041] (1) The alloy spring steel billet used in the preheating section is 50CrVA or other steel billets containing Cr and V.

[0042] (2) The temperature in the preheating section is controlled at 700°C and kept for 30 minutes;

[0043] (3) Heating the steel slab to 800°C in a tube furnace or resistance furnace and keeping it warm for 60 minutes. Nitrogen gas is introduced during the process. The flow rate of nitrogen gas is 4.5L / h to reduce the decarburization of the steel surface and ensure the service life of the steel;

[0044] (4) cooling the billet to 680°C at a cooling rate of 110°C / h, and then performing isothermal spheroidizing annealing at 680°C for 2 hours...

Embodiment 3

[0051] The invention provides a heat treatment process for alloy spring steel, which includes preheating, heating, isothermal spheroidizing annealing, quenching, cooling, medium temperature tempering, two shot peening treatments and processing inspection for a billet, specifically including the following steps:

[0052] (1) The alloy spring steel billet used in the preheating section is 50CrVA or other steel billets containing Cr and V.

[0053] (2) The temperature in the preheating section is controlled at 750°C and kept for 40 minutes;

[0054] (3) Heating the steel slab to 840°C in a tube furnace or resistance furnace and keeping it warm for 50 minutes. Nitrogen gas is introduced during the process. The flow rate of nitrogen gas is 5 / h to reduce the decarburization of the steel surface and ensure the service life of the steel;

[0055] (4) cooling the billet to 700°C at a cooling rate of 120°C / h, and then performing isothermal spheroidizing annealing at 700°C for 2 hours;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com