Open pit mine steep slope ecological restoration structure and restoration method

A technology for ecological restoration and mining, applied in infrastructure engineering, botanical equipment and methods, excavation, etc., can solve the problems of dead vegetation and inability to retain soil moisture and nutrients, so as to improve survival rate and alleviate soil water shortage Agglomeration, the effect of ensuring plant survival rate and growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

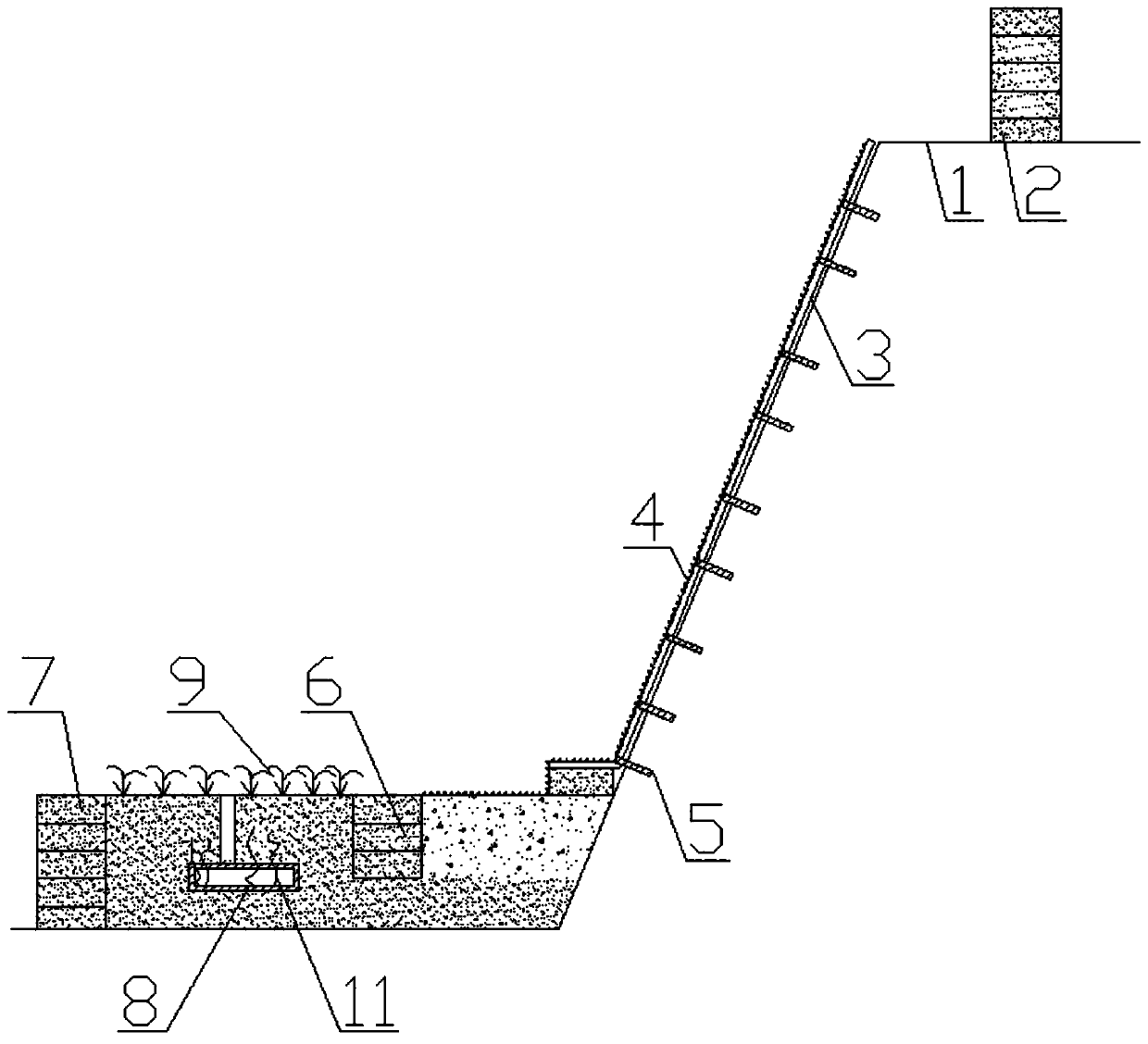

[0022] Basic as attached figure 1 Shown: an open-pit mine steep slope ecological restoration structure, including the first planting bag 2 at the top and bottom of the slope 1, the first planting bag 2 at the top of the slope 1 is set one meter away from the top of the slope 1, and two A whole piece of steel wire mesh 3 is laid on the slope 1 between the first planting bags 2. The steel wire mesh 3 is made of flexible galvanized steel wire mesh or plastic coated steel wire mesh, and the steel wire mesh 3 is made of high-quality low-carbon steel wire. The mesh surface is flat and the structure is firm. Even if the wire mesh 3 is partially cut or partially subjected to pressure, it will not loosen. The mesh shape of the wire mesh 3 can be diamond, oval, quadrilateral, Hexagonal and other shapes.

[0023] There are also vines 4 planted on the surface of the slope. The vines 4 can be vines such as creeper, linseed vine, ivy vine, trumpet creeper, honeysuckle, pueraria lobata, polygon...

Embodiment 2

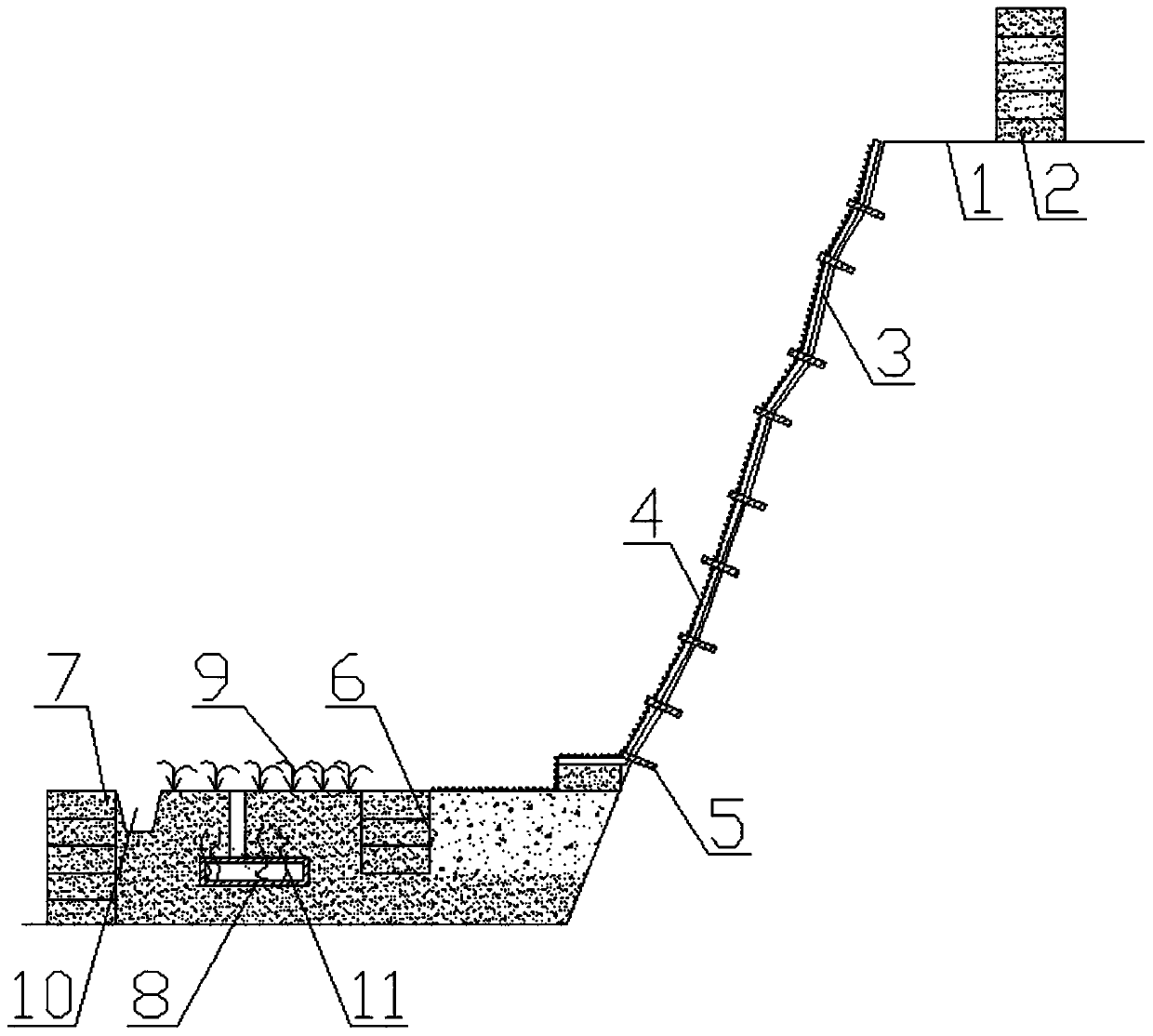

[0033] As attached figure 2 As shown, the difference between this embodiment and Embodiment 1 is only that it is aimed at the slope 1 with many steps, large height differences, and large water catchment surface. The repair structure in this embodiment only adds a drainage ditch 10. The intercepting drainage ditch 10 is arranged on the cultivated soil on the right side of the retaining wall 7, and drainage can be facilitated by the intercepting drainage ditch 10.

Embodiment 3

[0035] The difference between this embodiment and the first embodiment is that the retaining wall 7 adopts a stone cage. The diameter of the stones filled in the stone cage is between 20cm-40cm. Compared with the planting bag, the stone cage can enhance the stability of the retaining wall 7 , And the view of the gabion will be better than that of the plant bag, suitable for both sides of the road and sidewalk. For stone cages, there are usually many stones left on the side slope. If the retaining wall 7 adopts the stone cage, it can be used directly, which reduces the manufacturing cost of the retaining wall 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com