A control method for automatic bolting of hard rock tunneling machine

A technology for a hard rock roadheader and a control method, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve problems such as mechanical structure damage, steel arch collision, safety hazards, etc. Certainty, the effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

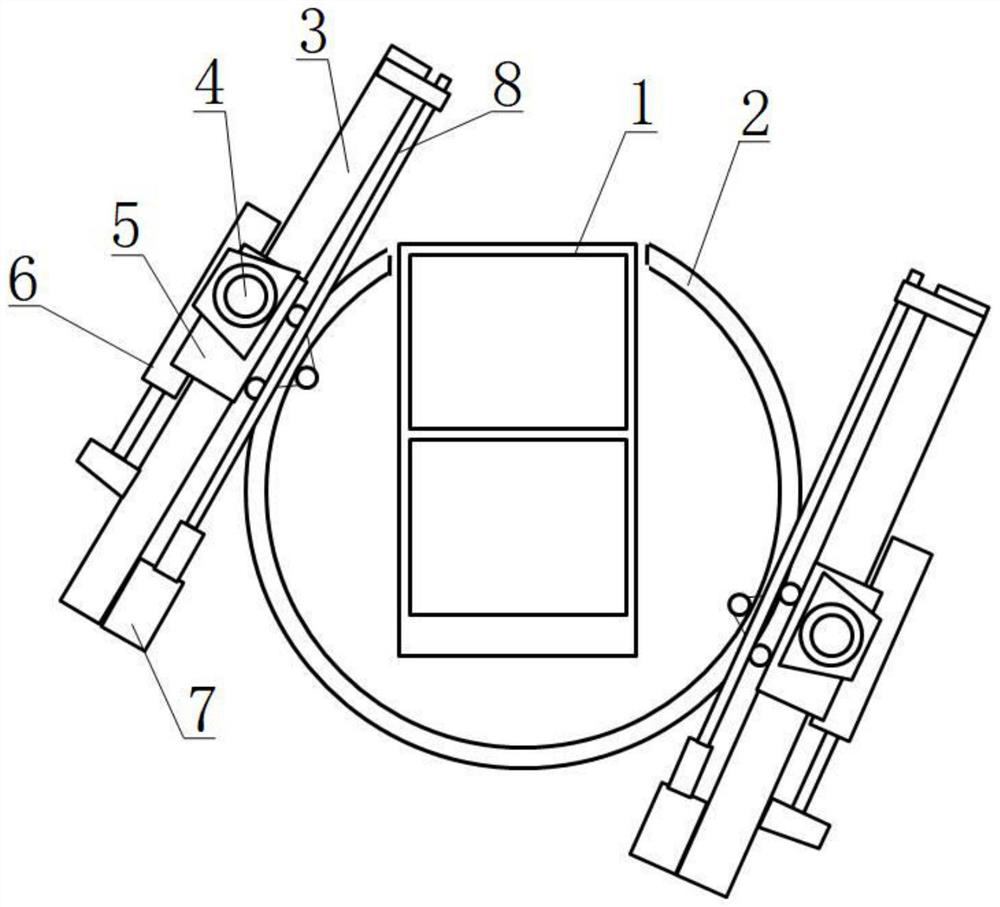

[0038] see Figure 1 ~ Figure 4 , TBM bolter system, including the main beam 1 of the roadheader, the arc ring gear 2, the push beam 3 connected to the arc ring gear, the swing cylinder 4 for adjusting the angle of the push beam, and the crawling trolley 5 for adjusting the position of the push beam , propulsion beam oil cylinder 6, rock drill 7 and bolt 8 installed on the propulsion beam; bolter system such as figure 1 shown.

[0039] On the bolter system, assemble the forward and backward travel travel sensor, crawler trolley encoder, swing cylinder encoder, propulsion beam oil cylinder pressure sensor, rock drill propulsion pressure sensor, and rock drill propulsion flow sensor.

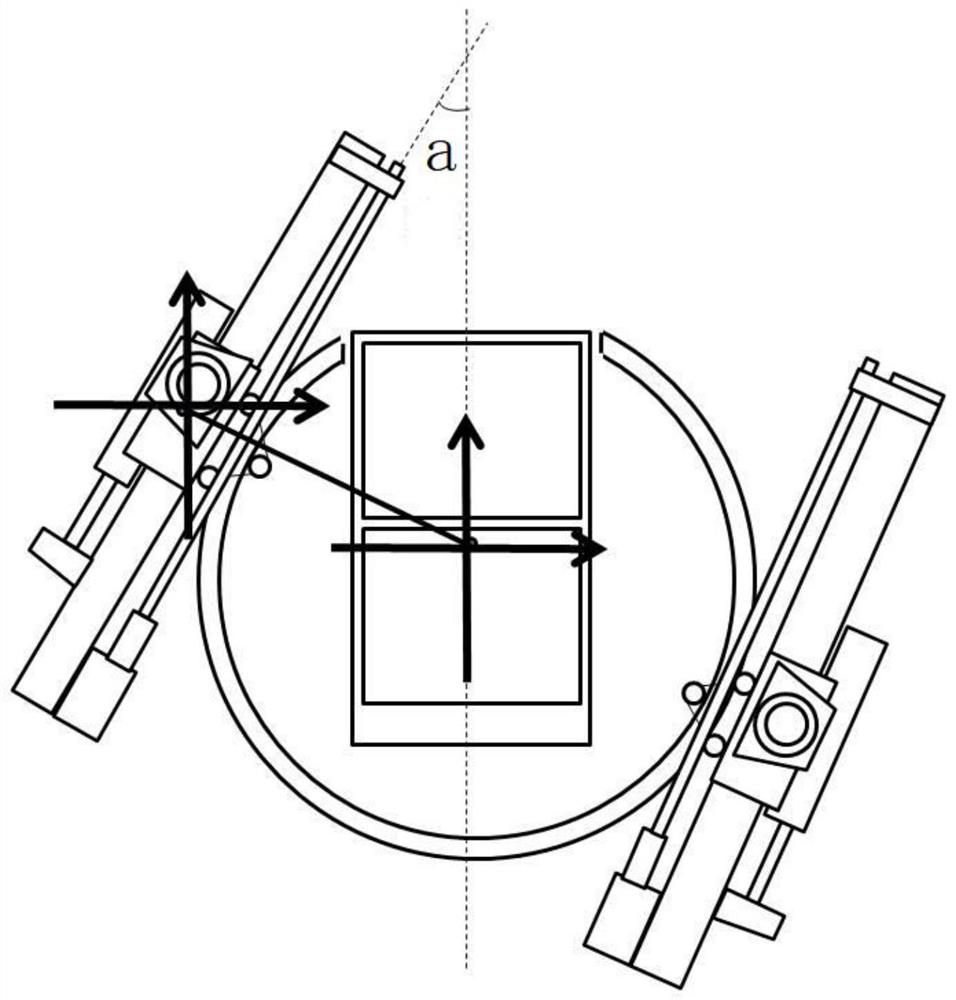

[0040] Set the positional relationship between the bolt hole and the tunnel axis, the number of bolts, the depth of the bolt and other parameters on the main controller, click start, and the TBM bolter system starts to drill the bolt automatically.

[0041] A method for controlling automatic bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com