A pressure test tubular mouth sealing device

A pressure test and sealing device technology, which is applied to the sealing of engines, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient operation and poor sealing effect, and achieve the advantages of convenient material acquisition, low cost and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

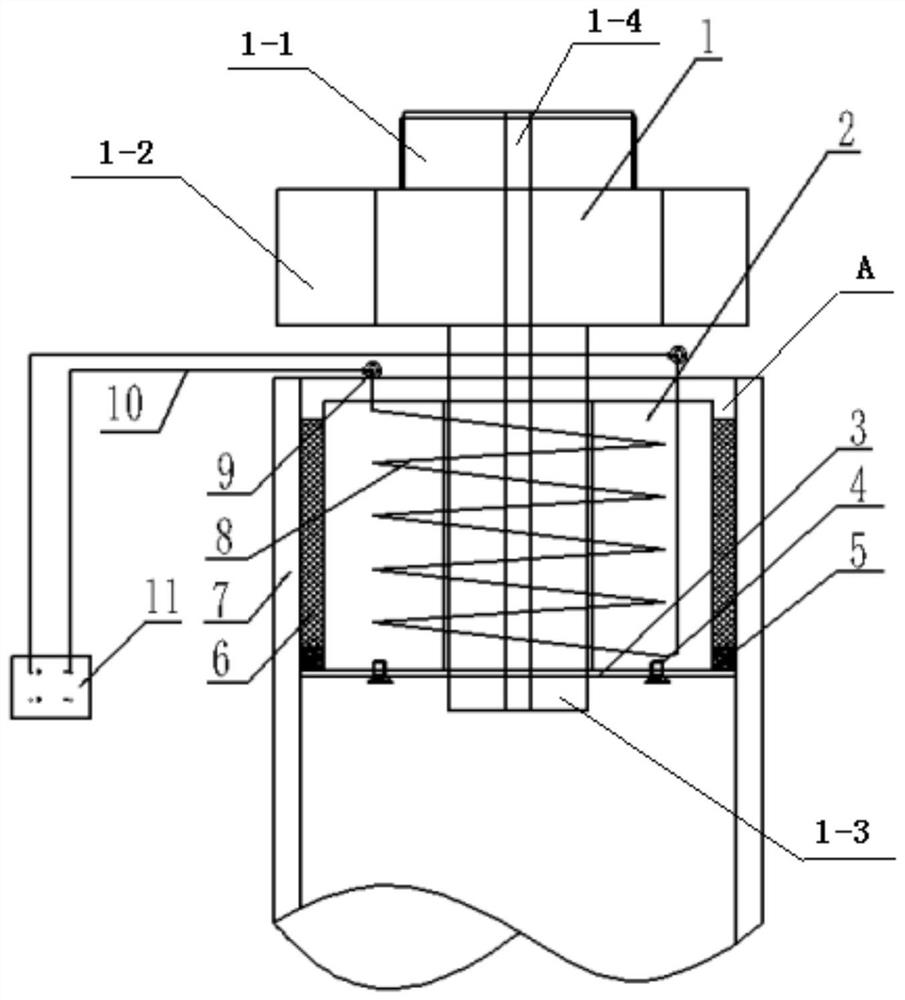

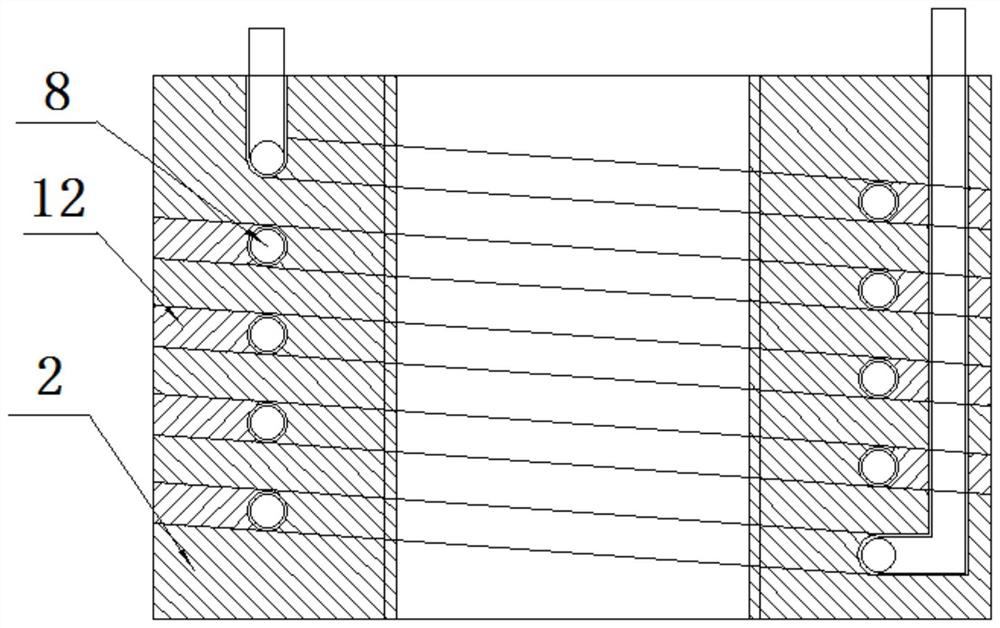

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, a pressure test tubular mouth sealing device of this embodiment includes an inner core 1, an outer core 2, an end piece 3, a sealing rope 5 and a sealing body 6, the outer core 2 is installed at the bottom of the inner core 1, and the outer The core 2 is embedded in the tubular mouth 7, the inner core 1, the outer core 2 and the tubular mouth 7 are arranged coaxially, a sealing gap A is left between the outer wall of the outer core 2 and the inner wall of the tubular mouth 7, and the end piece 3 can be It is disassembled and installed on the lower end surface of the outer core 2, and the end piece 3 is in interference fit with the inner side wall of the tubular mouth 7, and the sealing rope 5 and the sealing body 6 are sealed in the sealing gap A sequentially from bottom to top.

[0019] In this embodiment, the inner core 1 is connected to the outer core 2 by threaded connection.

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment, the inner core 1 of this embodiment comprises external connection segment 1-1, screw segment 1-2 and internal connection segment 1-3, external connection segment 1-1, screw segment 1-2 and internal connection Sections 1-3 are sequentially fixed and integrated from top to bottom, and the outer connection section 1-1, the screw section 1-2 and the inner connection section 1-3 are provided with a central through hole 1-4 along the axial direction. In this way, the external connection section 1-1 is an external thread structure for connecting with the outside, the internal connection section 1-3 is an external thread structure for connecting with the outer core 2, and the screw section 1-2 is for the convenience of Tightened hexagonal prism. Other compositions and connections are the same as in the first embodiment.

[0021] The central through hole 1-4 of this embodiment is used to inject pr...

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 This embodiment will be described. The end piece 3 of this embodiment is made of copper sheet, and the thickness of the end piece 3 is less than 1 mm. Such setting has elastic deformation, and the thickness of the end piece is less than 1mm, so that when the sealing body formed with the inner core 1 and the outer core 2 enters the tubular opening 7, it can be uniformly and freely deformed into a concave bottom shape, and when it encounters a gap smaller than the sealing member gap Foreign matter can pass through by itself, which increases the versatility, and other components and connections are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com