Ultra-precision concentrated sulfuric acid filtering device and filtering method

A filtration method, concentrated sulfuric acid technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems affecting the quality of concentrated sulfuric acid, achieve perfect instantaneous recoil effect, obvious effect, and uniform porosity and fine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention is described in further detail:

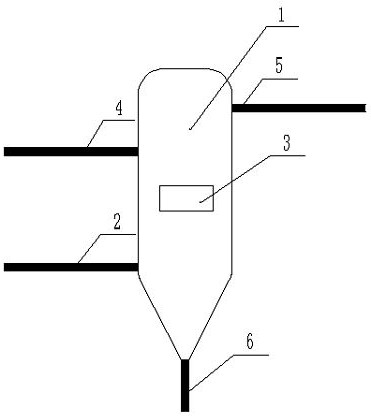

[0035] Such as Figure 1 to Figure 4 As shown, a device for ultra-precision filtering concentrated sulfuric acid includes a main body device 1, a first pipeline 2 for the inflow of concentrated sulfuric acid to be filtered is arranged on the lower side of the main body device 1, and a device for ultra-precision filtering the concentrated sulfuric acid to be filtered is arranged inside. The filter element 3, on one side of the upper part, is provided with the second pipe 4 for discharging the concentrated sulfuric acid overflowed after recoiling the filter element 3; There is a fourth pipeline 6 through which the filter residue filtered by the concentrated sulfuric acid is discharged, and the filtered filter residue is compressed into a filter cake, which can be used as raw fuel for sintering and realizes no waste discharge. The filter element 3 is provided with a PM membrane, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com