A method for quasi-continuous synthesis of single-atom catalysts

A catalyst and quasi-continuous technology, applied in the field of materials science and engineering, can solve the problems of low efficiency and achieve the effects of simple preparation method, increased output, good scalability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

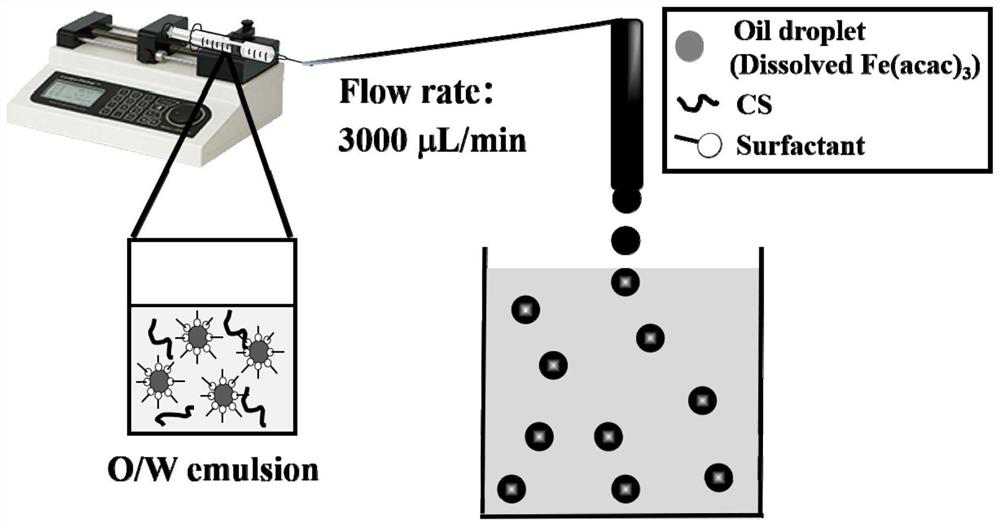

[0030] Chitosan was dissolved in 300 mL of deionized water as the continuous phase, and 1.5 g of iron acetylacetonate was dissolved in 30 mL of ethyl acetate as the dispersed phase. Then the dispersed phase was added dropwise to the continuous phase solution and sheared at 13000 rpm for 5 min. The emulsion was injected into a quartz capillary device (550 μm in outer diameter) at a flow rate of 2000 μL / min using a syringe pump, and then dropped into a coagulation bath containing 2 w / v% SDS to form microcapsules. After continuous synthesis for 1 h, the microcapsules were washed with deionized water and then freeze-dried with a freeze dryer. The obtained microcapsules were in N 2 900 under the protection of atmosphere o C pyrolysis for 2 h. then at 80 o C with 0.5 MH 2 SO 4 The iron single-atom catalyst can be obtained after washing for 12 hours and drying.

Embodiment 2

[0032] Chitosan was dissolved in 300 mL of deionized water as the continuous phase, and 1.5 g of iron acetylacetonate was dissolved in 30 mL of ethyl acetate as the dispersed phase. Then the dispersed phase was added dropwise to the continuous phase solution and sheared at 13000 rpm for 5 min. The emulsion was injected into a quartz capillary device (550 μm in outer diameter) at a flow rate of 2000 μL / min using a syringe pump, and then dropped into a coagulation bath containing 2 w / v% SDS to form microcapsules. After continuous synthesis for 2 h, the microcapsules were washed with deionized water and then freeze-dried with a freeze dryer. The obtained microcapsules were in N 2 900 under the protection of atmosphere o C pyrolysis for 2 h. then at 80 o C with 0.5 MH 2 SO 4 The iron single-atom catalyst can be obtained after washing for 12 hours and drying.

Embodiment 3

[0034] Chitosan was dissolved in 300 mL of deionized water as the continuous phase, and 0.9 g of cobalt acetylacetonate was dissolved in 30 mL of ethyl acetate as the dispersed phase. Then the dispersed phase was added dropwise to the continuous phase solution and sheared at 13000 rpm for 5 min. The emulsion was injected into a quartz capillary device (550 μm in outer diameter) at a flow rate of 2000 μL / min using a syringe pump, and then dropped into a coagulation bath containing 2 w / v% SDS to form microcapsules. After continuous synthesis for 1 h, the microcapsules were washed with deionized water and then freeze-dried with a freeze dryer. The obtained microcapsules were in N 2 900 under the protection of atmosphere o C pyrolysis for 2 h. then at 80 o C with 0.5 MH 2 SO 4 The cobalt single-atom catalyst can be obtained after washing for 12 hours and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com