A production control method for film thickness of high-precision color-coated sheet

A production control method and technology for color-coated boards, which are applied in the directions of coatings, devices for coating liquid on surfaces, pre-treatment of surfaces, etc., can solve the problems of paint waste, inconsistent performance of color-coated boards, etc., and achieve simple and effective operation methods. The production parameters are easy to adjust and the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

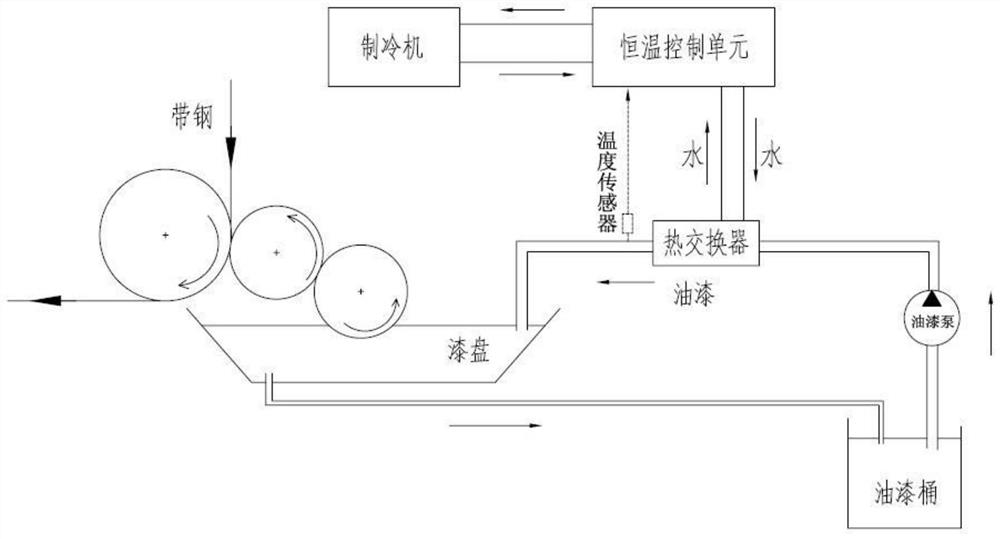

Method used

Image

Examples

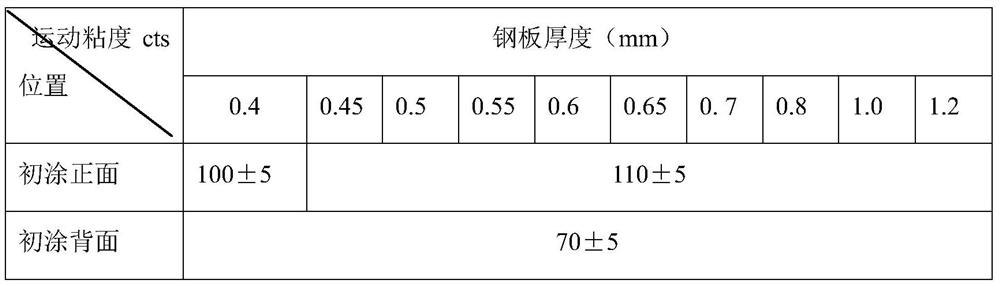

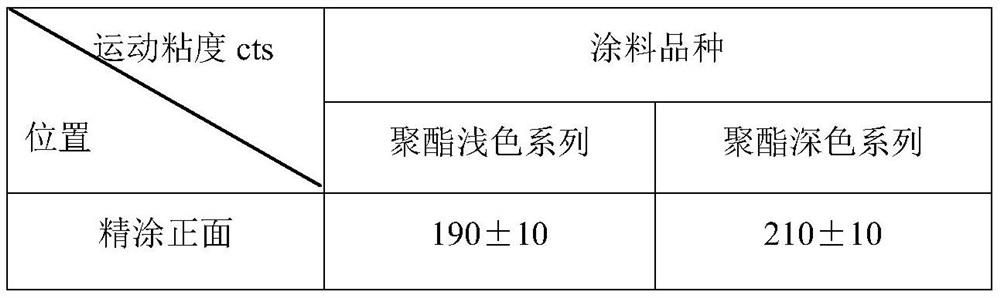

Embodiment 1

[0045] The coating temperature is 35 °C, the color coating varieties are epoxy primer, polyester light color series (white ash) topcoat, the thickness of the steel plate is 0.5mm, and the unit speed is 120m / min. The viscosity value of the front of the first coating is 107.4cts, the viscosity value of the back of the first coating is 66.4cts, the viscosity value of the front of the fine coating is 194.2cts, and the viscosity value of the back of the fine coating is 75.5cts; the roll speed of the first coating front with material is 52.4m / min, the roll speed of the coating roller is 140.2m / min, the roll speed of the back of the first coating is 50.6m / min, and the roll speed of the coating roller is 141.5m / min; the pressure of the tape roller on the front of the first coating is 1820kg. The pressure of the coating roller is 220kg, the roll speed of the fine coating front strip roll is 60.3m / min, the roll speed of the coating roller is 139.1m / min, the roll speed of the fine coating ba...

Embodiment 2

[0047] The coating temperature is 35 °C, the color coating variety is epoxy primer, polyester light color series (white ash) topcoat, the thickness of the steel plate is 0.5mm, and the unit speed is 135m / min. The viscosity value of the front side of the first coating is 109.5cts, the viscosity value of the back of the first coating is 67.9cts, the viscosity value of the front of the fine coating is 196.3cts, and the viscosity value of the back of the fine coating is 74.9cts; the roll speed of the first coating front with material is 50.1m / min, the roll speed of the coating roller is 153.2m / min, the roll speed of the back of the first coating is 50.4m / min, and the roll speed of the coating roller is 152.3m / min; the pressure of the tape roller on the front of the first coating is 1815kg. The pressure of the coating roller is 215kg, the roll speed of the fine coating front strip roll is 60.8m / min, the roll speed of the coating roller is 153.2m / min, the roll speed of the fine coating ...

Embodiment 3

[0049]The coating temperature is 33 °C, the color coating varieties are epoxy primer, polyester dark series (sea blue) topcoat, the thickness of the steel plate is 0.5mm, and the unit speed is 120m / min. The viscosity value of the front side of the first coating is 108.2cts, the viscosity value of the back side of the first coating is 70.6ts, the viscosity value of the front side of the fine coating is 210.3cts, and the viscosity value of the back of the fine coating is 78.3cts; the roll speed of the first coating front with material is 51.3m / min, the roll speed of the coating roller is 139.2m / min, the roll speed of the back of the first coating is 49.2m / min, and the roll speed of the coating roller is 141.2m / min; the pressure of the tape roller on the front of the first coating is 1780kg. The pressure of the coating roller is 216kg, the roll speed of the fine coating front strip roll is 61.1m / min, the roll speed of the coating roller is 141.2m / min, the roll speed of the fine coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com