Method for preparing crystal high-purity phosphorous acid by purifying byproduct phosphorous acid in pivaloyl chloride production

A technology of pivaloyl chloride and phosphorous acid, applied in phosphorous acid, phosphorus oxyacid and other directions, can solve the problems of imperfect cooling function, rising temperature of the outer wall of the device, slow heat dissipation of materials, etc., to improve the utilization value and ensure uniformity. Good effect of sex and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of pivaloyl chloride production by-product phosphorous acid purifies the method for crystal high-purity phosphorous acid, comprises the steps:

[0042] Step 1: Dilute phosphorous acid, a by-product of pivaloyl chloride production, with evaporating condensed water to a content of 60%-70% of phosphorous acid. Phosphorous acid, a by-product of pivaloyl chloride production, is not limited to the low-concentration by-product phosphorous acid produced in this industry, including the synthesis of dichloropropanol by glycerin chlorination, propylene oxide, propionyl chloride and other industries; the diluted concentration of phosphorous acid 60%-70% is particularly important for the filtration of impurities. If the concentration is too high, it is not conducive to filtering impurities. Of course, if the concentration is too low, it will consume a lot of heat energy during subsequent concentration.

[0043] In step 1, diluting low-concentration industrial by-product phosp...

Embodiment 2

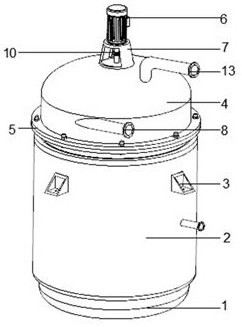

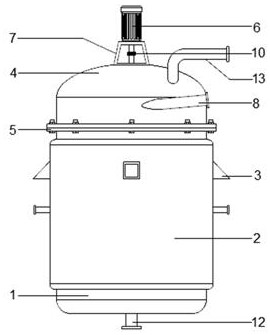

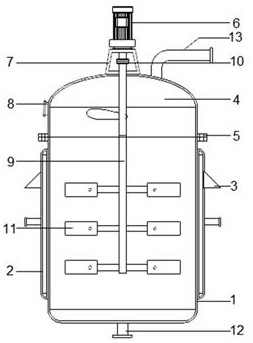

[0051] as attached Figure 1-3 As shown, the evaporation and concentration kettle with stirring function includes: the first kettle body 1, the jacket 2, the fixing seat 3, the kettle cover 4, the flange 5, the driving motor 6, the motor support 7, the feeding pipe 8, Stirring shaft 9, coupling 10, paddle 11, discharge pipe 12, connecting pipe 13; the outer side of the first kettle body 1 is provided with a jacket 2, and the first kettle body 1 and the jacket 2 are connected by welding ; The fixed seat 3 is arranged on the side of the jacket 2, and the fixed seat 3 is connected with the jacket 2 by welding; Connected by the flange 5; the drive motor 6 is arranged on the top of the kettle cover 4, and the drive motor 6 is connected with the kettle cover 4 through the motor support 7; the feed pipe 8 is arranged on one side of the kettle cover 4, and the feeding The pipe 8 is connected with the kettle cover 4 by welding; the stirring shaft 9 is arranged at the bottom of the ket...

Embodiment 3

[0057] as attached Figure 4-6 As shown, the cooling kettle with stirring function includes the second kettle body B1, the kettle cover B101, the inner cylinder B102, the installation plate B2, the display B3, the feed port B4, the discharge port B5, the water inlet B6, and the drain port B7 , temperature sensor B8, geared motor B9, rotating shaft B10, helical blade B11, casing B12.

[0058] The two parts on the upper side of the second kettle body B1 are respectively provided with a kettle cover B101, and the second kettle body B1 and the kettle cover B101 are connected by welding; It is connected with the kettle cover B101 by welding; the installation plate B2 is arranged on the outside of the second kettle body B1, and the installation plate B2 is connected with the second kettle body B1 by welding; the display B3 is set on the front side of the second kettle body B1 On the left, and the display B3 is connected with the second kettle body B1 by means of bolt fixing; the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com