Low-cost wrought magnesium alloy strengthened by light rare earth elements Ce and Sm and preparation method of low-cost wrought magnesium alloy

A technology of light rare earth elements and deformed magnesium alloys, applied in the field of magnesium alloy materials, can solve the problems of low price of light rare earth elements, underutilization of value, high cost and large-scale application, so as to promote dynamic recrystallization behavior and promote small horn crystals Boundaries and dislocations, the effect of refining the extruded grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

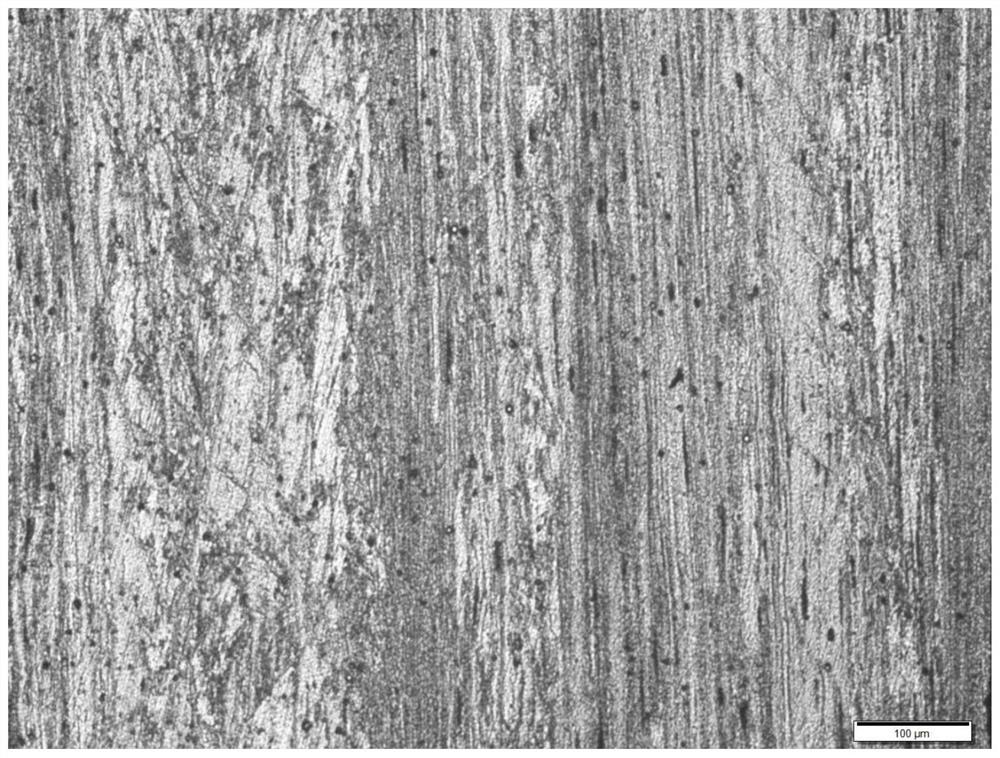

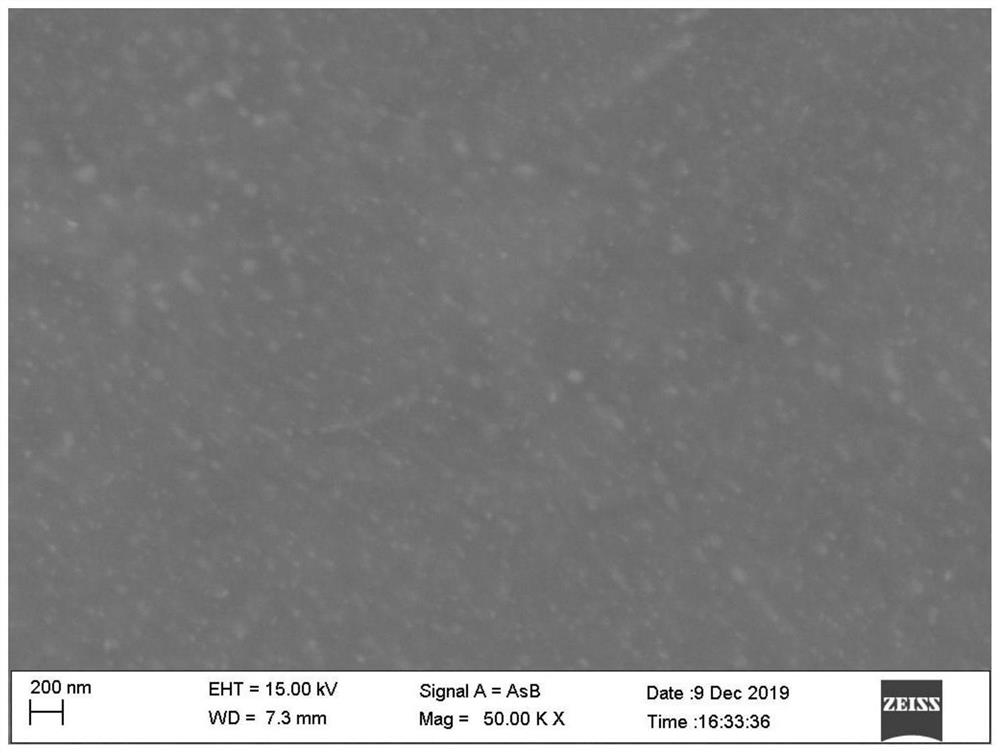

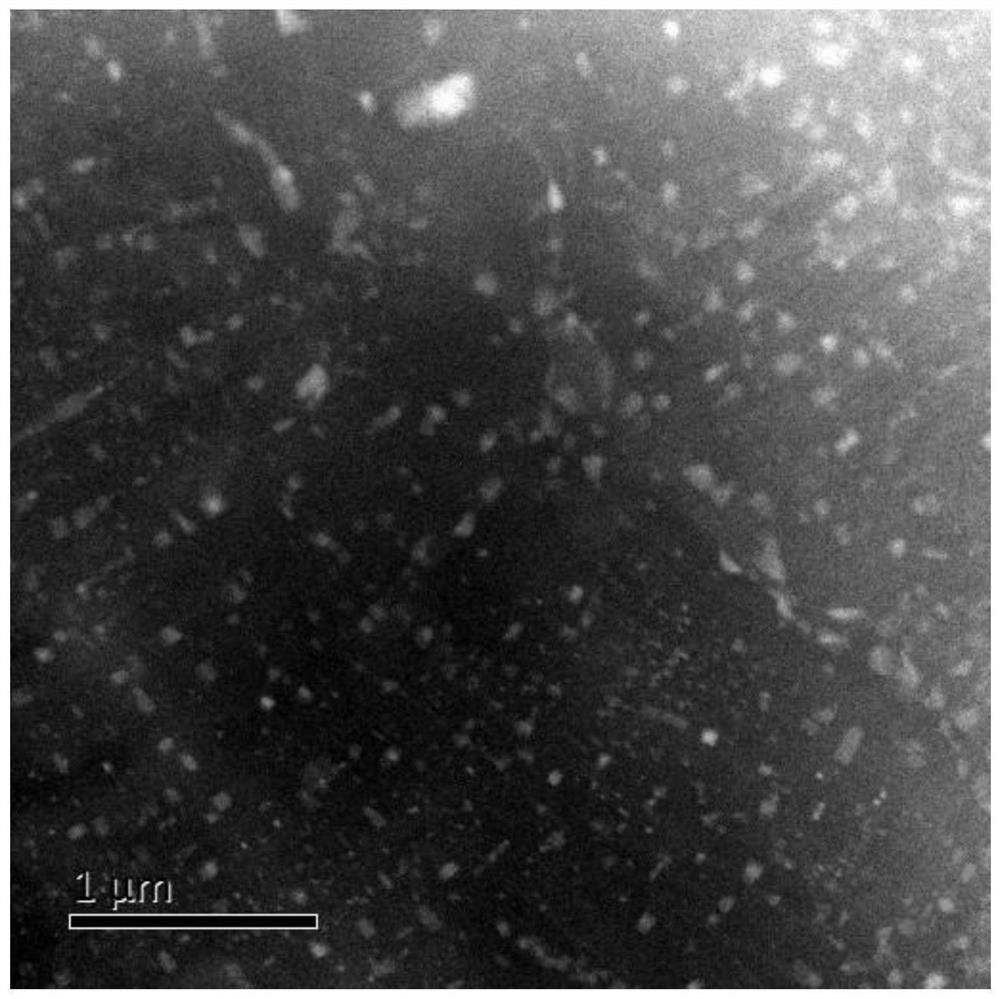

Image

Examples

Embodiment 1

[0024] High-strength wrought magnesium alloy Mg-0.2Ce-0.5Sm containing light rare earth elements, the components are: 0.2wt.% Ce, 0.5wt.% Sm, and the balance is Mg.

[0025] The preparation method of the high-strength wrought magnesium alloy containing light rare earth elements of this embodiment is:

[0026] (1) Weigh the following components according to mass percentage: 0.2 wt.% cerium, 0.5 wt.% samarium, the balance is magnesium, cerium is pure cerium or magnesium cerium master alloy, samarium is pure samarium or magnesium samarium master alloy;

[0027] (2) Ingot smelting: Under the protection of high-purity argon, heat industrially pure magnesium until it melts, add alloy elements Ce and Sm, stir thoroughly after melting, remove the scum on the surface after standing still, and cast to preheated In the mould, an ingot of deformed magnesium alloy containing cerium is obtained;

[0028] (3) Homogenization treatment: Cover the ingot with graphite powder to isolate the air,...

Embodiment 2

[0032] High-strength wrought magnesium alloy Mg-0.5Ce-1Sm containing light rare earth elements, the components are: 0.5 wt.% Ce, 1.0 wt.% Sm, and the balance is Mg.

[0033] The preparation method of the high-strength wrought magnesium alloy containing light rare earth elements of this embodiment is:

[0034] (1) Weigh the following components according to mass percentage: 0.5 wt.% cerium, 1.0 wt.% samarium, the balance is magnesium, cerium is pure cerium or magnesium cerium master alloy, samarium is pure samarium or magnesium samarium master alloy;

[0035] (2) Ingot smelting: Under the protection of high-purity argon, heat industrially pure magnesium until it melts, add alloy elements Ce and Sm, stir thoroughly after melting, remove the scum on the surface after standing still, and cast to preheated In the mould, an ingot of deformed magnesium alloy containing cerium is obtained;

[0036] (3) Homogenization treatment: Cover the ingot with graphite powder to isolate the air,...

Embodiment 3

[0040] The high-strength wrought magnesium alloy Mg-1.2Ce-1Sm containing light rare earth elements is composed of 1.2wt.% Ce, 1.0wt.% Sm, and the balance is Mg.

[0041] The preparation method of the high-strength wrought magnesium alloy containing light rare earth elements of this embodiment is:

[0042] (1) Weigh the following components according to mass percentage: 1.2 wt.% cerium, 1.0 wt.% samarium, the balance is magnesium, cerium is pure cerium or magnesium cerium master alloy, samarium is pure samarium or magnesium samarium master alloy;

[0043] (2) Ingot smelting: Under the protection of high-purity argon, heat industrially pure magnesium until it melts, add alloy elements Ce and Sm, stir thoroughly after melting, remove the scum on the surface after standing still, and cast to preheated In the mould, an ingot of deformed magnesium alloy containing cerium is obtained;

[0044] (3) Homogenization treatment: Cover the ingot with graphite powder to isolate the air, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com