Repair system for concrete cracks

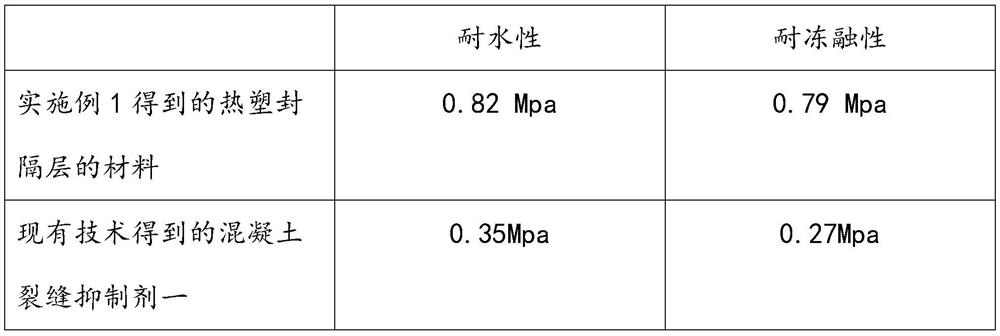

A concrete and crack technology, applied in the field of concrete crack repair system, can solve the problems of bottom wall deformation and fission, insufficient freeze-thaw resistance, bottom wall cracks, etc., to prevent thermal stress, better shear strength, and water resistance. and better freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

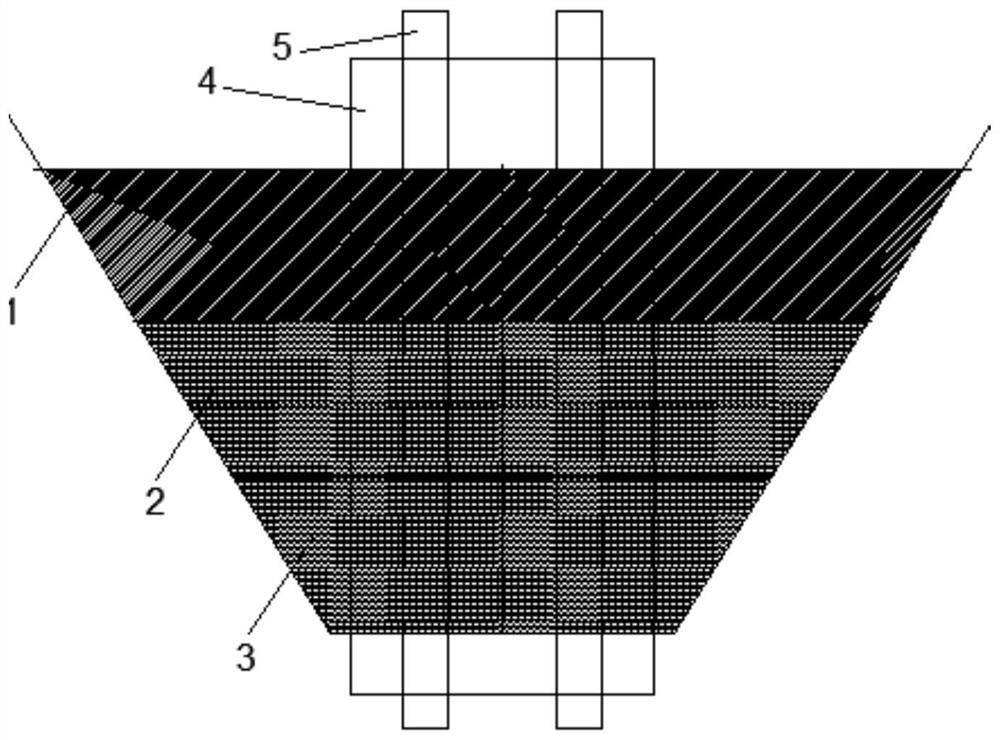

[0041] Such as figure 1 As shown, the repair system for concrete cracks includes an epoxy resin layer 1, a thermoplastic sealing layer 2, and a base encapsulation growth layer 3 that are sequentially arranged from the crack surface along the crack depth direction to the bottom wall in the crack;

[0042] It also includes an auxiliary thermal layer 4 penetrating through the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the base package growth layer 3 .

[0043] The thickness ratio of the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the substrate packaging growth layer 3 is: 1:1:1.

[0044] The material of the base encapsulation growth layer 3 is a concrete crack inhibitor, and the preparation method of the concrete crack inhibitor comprises the following steps:

[0045] (1) Synthesis of β-cyclodextrin powder containing multiple double bonds: first disperse β-cyclodextrin in anhydrous dimethyl sulfoxide, and gradually add dropwise acryloyl chloride ...

Embodiment 2

[0079] A repair system for concrete cracks, including an epoxy resin layer 1, a thermoplastic sealing layer 2, and a substrate encapsulation growth layer 3, which are sequentially arranged from the crack surface along the crack depth direction to the bottom wall of the crack;

[0080] It also includes an auxiliary thermal layer 4 penetrating through the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the base package growth layer 3 .

[0081] The thickness ratio of the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the substrate packaging growth layer 3 is: 1:1:1.

[0082] The material of the base encapsulation growth layer 3 is a concrete crack inhibitor, and the preparation method of the concrete crack inhibitor comprises the following steps:

[0083] (1) Synthesis of β-cyclodextrin powder containing multiple double bonds: first disperse β-cyclodextrin in anhydrous dimethyl sulfoxide, and gradually add dropwise acryloyl chloride containing 10wt% mass...

Embodiment 3

[0116] A repair system for concrete cracks, including an epoxy resin layer 1, a thermoplastic sealing layer 2, and a substrate encapsulation growth layer 3, which are sequentially arranged from the crack surface along the crack depth direction to the bottom wall of the crack;

[0117] It also includes an auxiliary thermal layer 4 penetrating through the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the base package growth layer 3 .

[0118] The thickness ratio of the epoxy resin layer 1 , the thermoplastic sealing layer 2 and the substrate packaging growth layer 3 is: 1:1:1.

[0119] The material of the base encapsulation growth layer 3 is a concrete crack inhibitor, and the preparation method of the concrete crack inhibitor comprises the following steps:

[0120] (1) Synthesis of β-cyclodextrin powder containing multiple double bonds: first disperse β-cyclodextrin in anhydrous dimethyl sulfoxide, and gradually add dropwise acryloyl chloride containing 10wt% mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com