Oil refining additive drying and conveying device

A conveying device and drying technology, which is applied in the directions of drying gas arrangement, drying solid materials, drying, etc., can solve the problems of uneven drying, heating, affecting drying effect, etc., and achieve the effect of improving efficiency and synchronizing drying degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

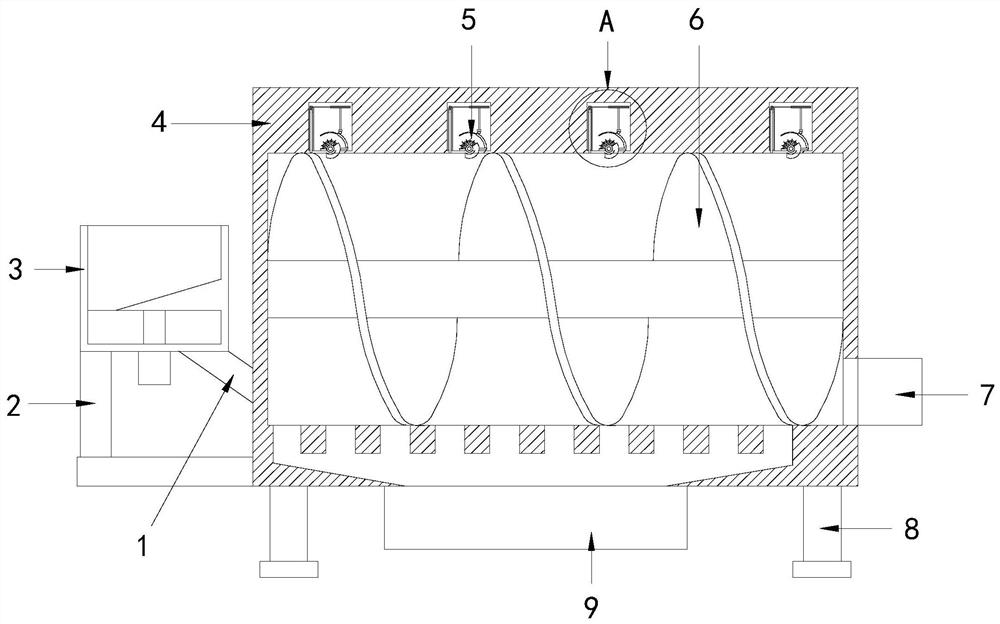

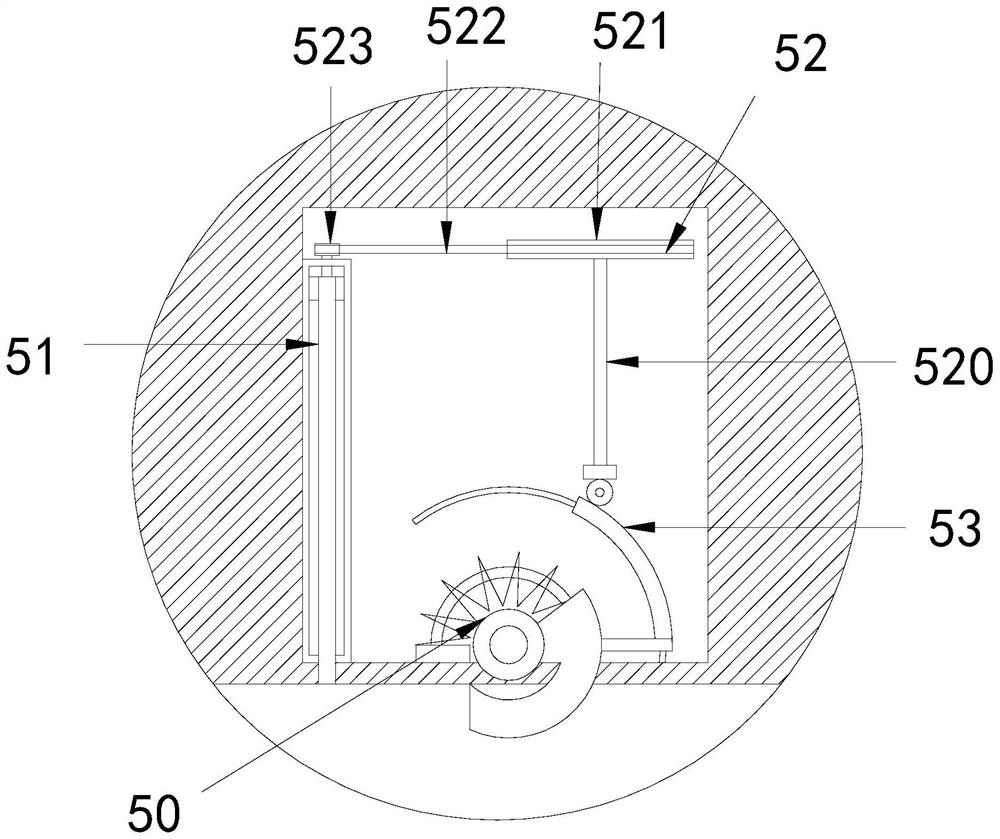

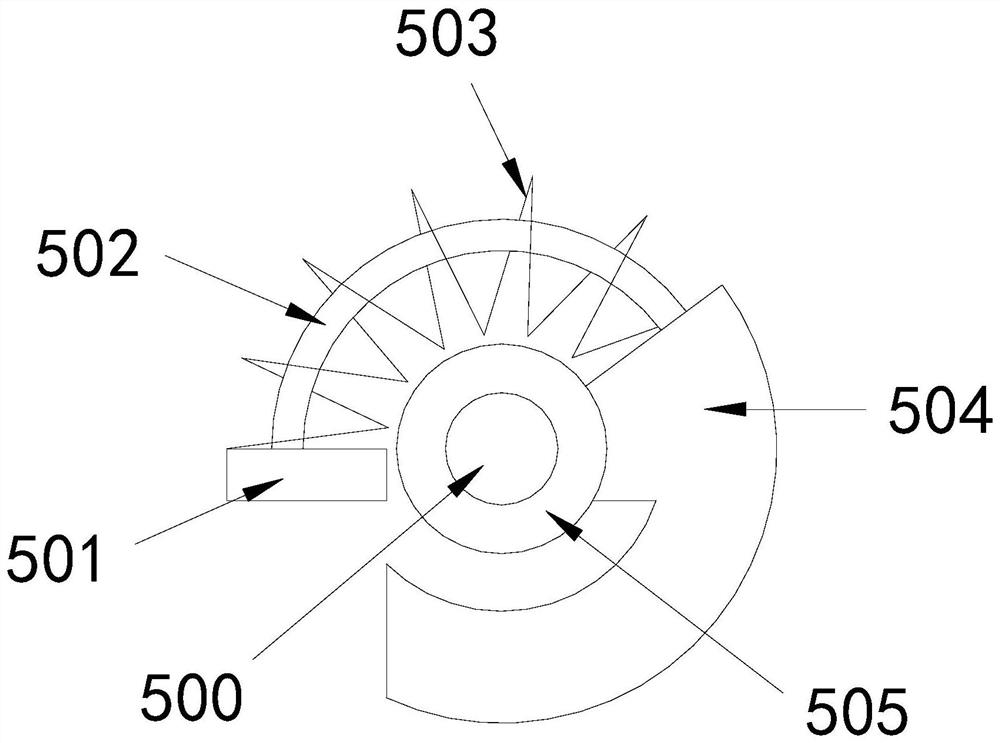

[0026] see Figure 1-5 , the present invention provides a technical solution for drying and conveying equipment for oil refining aids: its structure includes a feed pipe 1, a bracket 2, a material cylinder 3, a drying cylinder 4, an auxiliary structure 5, a screw rod 6, an outlet 7, a foot 8, and a heating device 9. The bottom of the drying cylinder 4 is connected with a heating device 9, the two ends of the drying cylinder 4 are welded with feet 8, one end of the drying cylinder 4 is provided with an outlet 7, and the other end is connected with the barrel 3 through the feeding pipe 1 , the barrel 3 is connected to the side of the drying barrel 4 through the bracket 2, the inner wall of the drying barrel 4 is provided with a mounting groove, and an auxiliary structure 5 is installed in the mounting groove, and the auxiliary structure 5 includes a power structure 50, a moving structure 51. Enlarging structure 52, transmission structure 53, the power structure 50 is connected t...

Embodiment 2

[0029] see Figure 1-5, the present invention provides a technical solution for drying and conveying equipment for oil refining aids: its structure includes a feed pipe 1, a bracket 2, a material cylinder 3, a drying cylinder 4, an auxiliary structure 5, a screw rod 6, an outlet 7, a foot 8, and a heating device 9. The bottom of the drying cylinder 4 is connected with a heating device 9, the two ends of the drying cylinder 4 are welded with feet 8, one end of the drying cylinder 4 is provided with an outlet 7, and the other end is connected with the barrel 3 through the feeding pipe 1 , the barrel 3 is connected to the side of the drying barrel 4 through the bracket 2, the inner wall of the drying barrel 4 is provided with a mounting groove, and an auxiliary structure 5 is installed in the mounting groove, and the auxiliary structure 5 includes a power structure 50, a moving structure 51. Enlarging structure 52, transmission structure 53, the power structure 50 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com