Device and method for measuring lightning impact force and lightning fracture damage of carbon fiber laminates

A carbon fiber layer, measuring device technology, applied in the direction of measuring device, force/torque/work measuring instrument, measuring electricity, etc., can solve the problem that the instantaneous relationship cannot be accurately given, the impact force dispersion is large, and the lightning impact force cannot be fully characterized. Aircraft structure impact force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

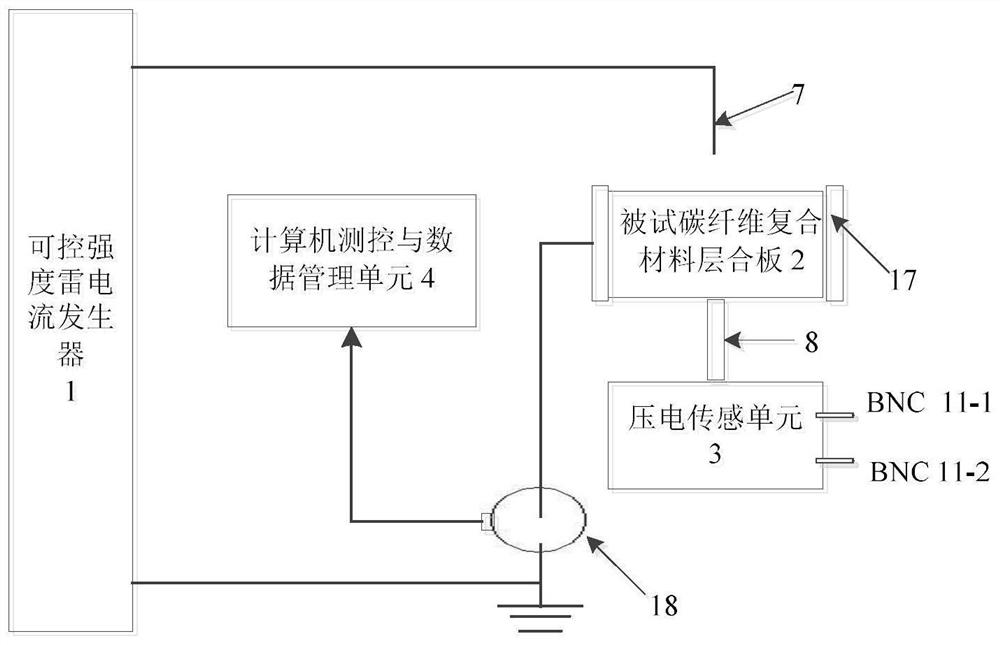

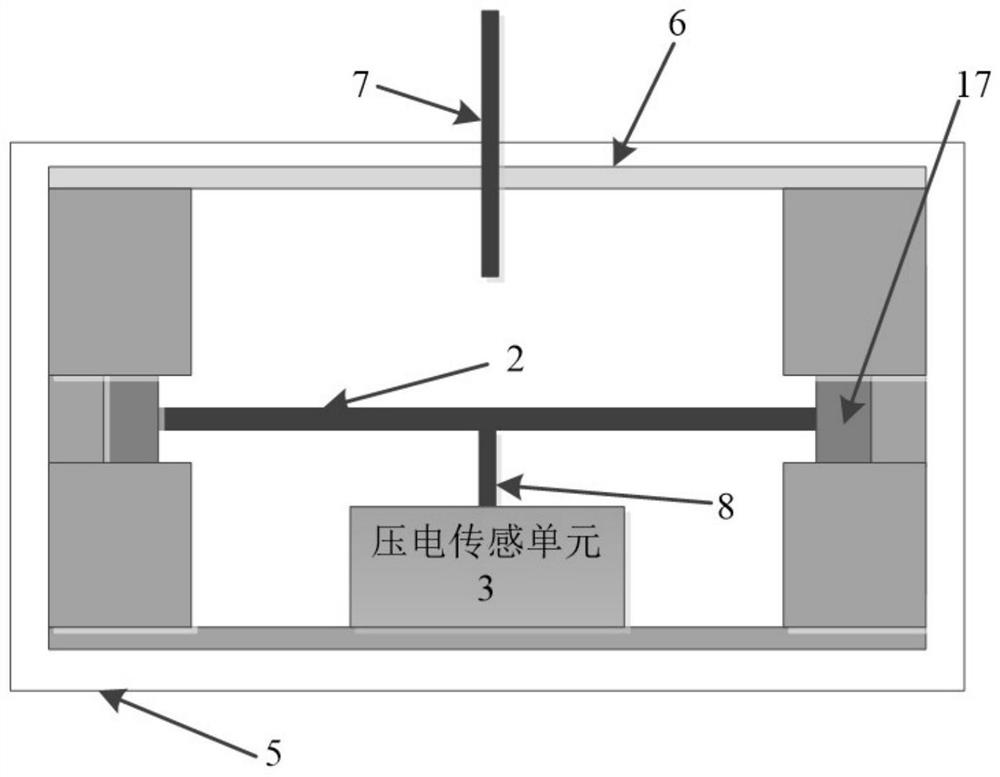

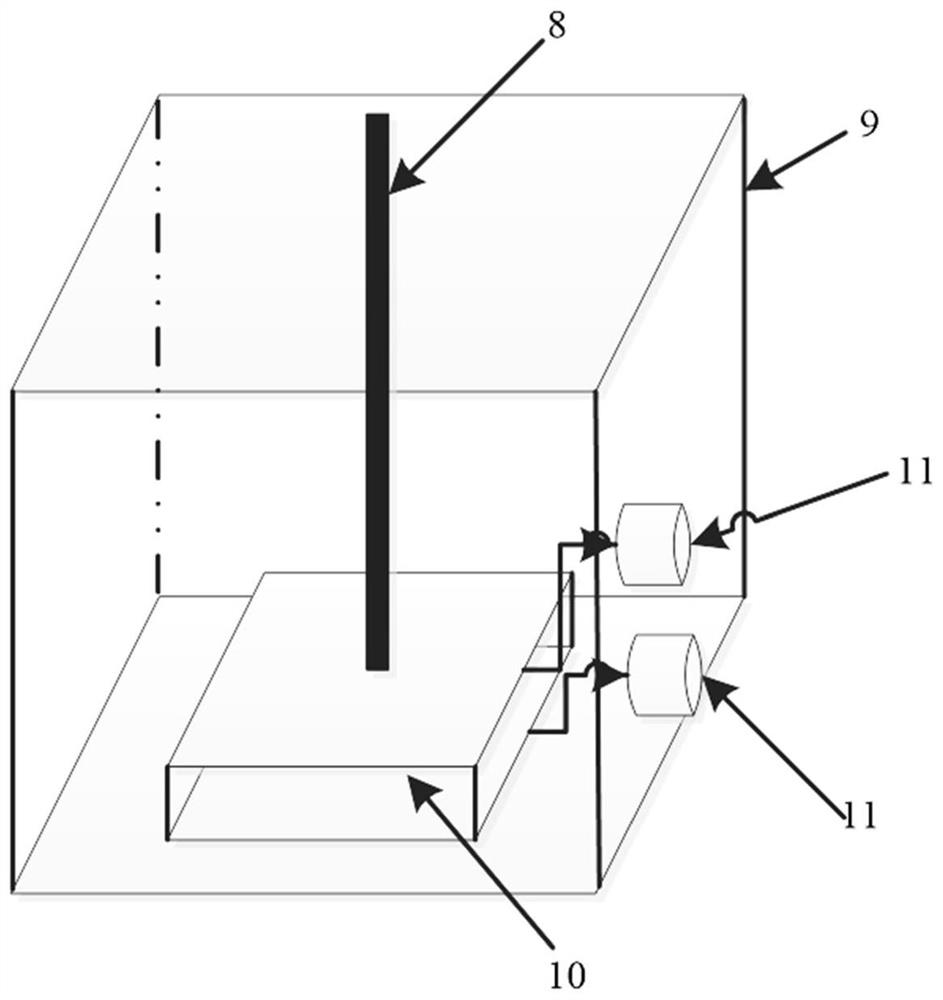

[0038] see figure 1 , the measuring device of lightning strike impact force and carbon fiber lightning fracture damage with common mode interference suppression performance under strong electromagnetic interference of the present invention includes a controllable intensity lightning current generator 1, a carbon fiber composite material laminate 2 to be tested, a piezoelectric sensor Unit 3 and computer measurement and control and data management unit 4. The high-voltage end of the controllable intensity lightning current generator 1 is connected to the metal rod-shaped electrode 7 installed on the insulating cover plate 6 in the experimental fixture 5, and the metal rod-shaped electrode 7 is perpendicular to the upper surface of the carbon fiber composite laminate 2 to be tested. For the center of the tested carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com