Energy-saving and environment-friendly limestone-gypsum wet flue gas desulfurizing tower

A wet flue gas desulfurization, energy saving and environmental protection technology, applied in the field of flue gas desulfurization, can solve the problems of inconvenient waste water backflow, inconvenient addition of limestone reactants, reactant consumption, etc., to improve efficiency, uniform and complete contact, and improve the degree of reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

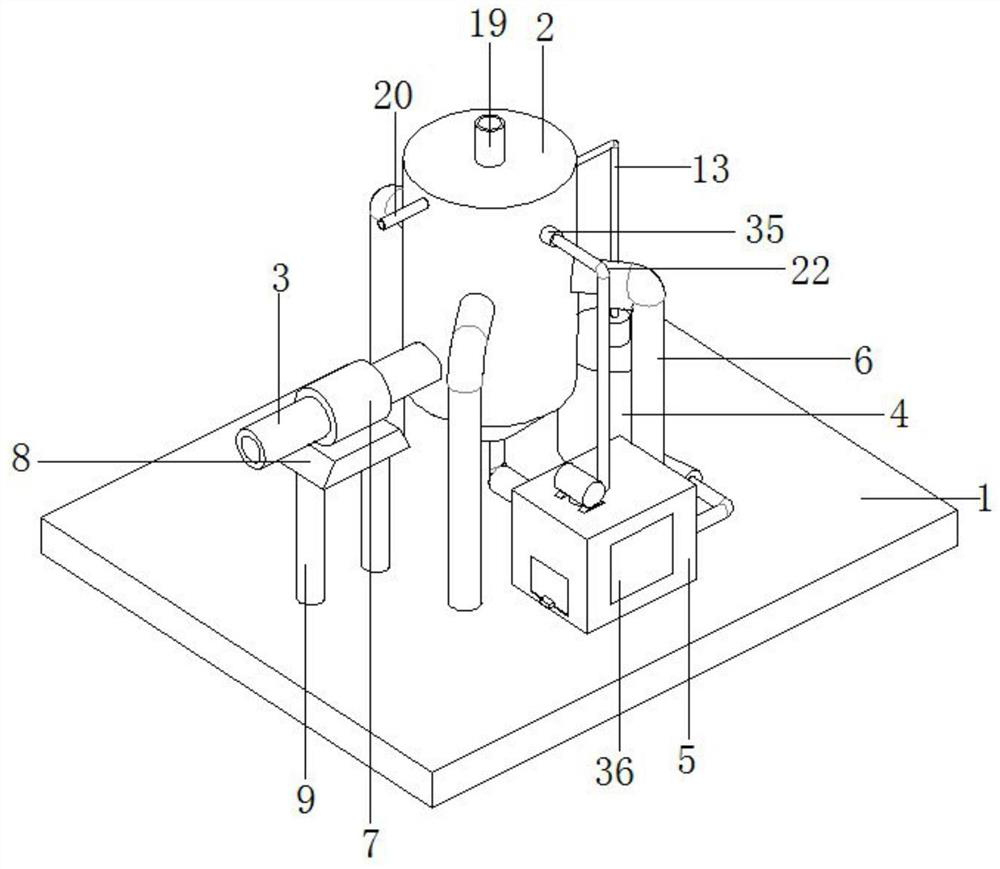

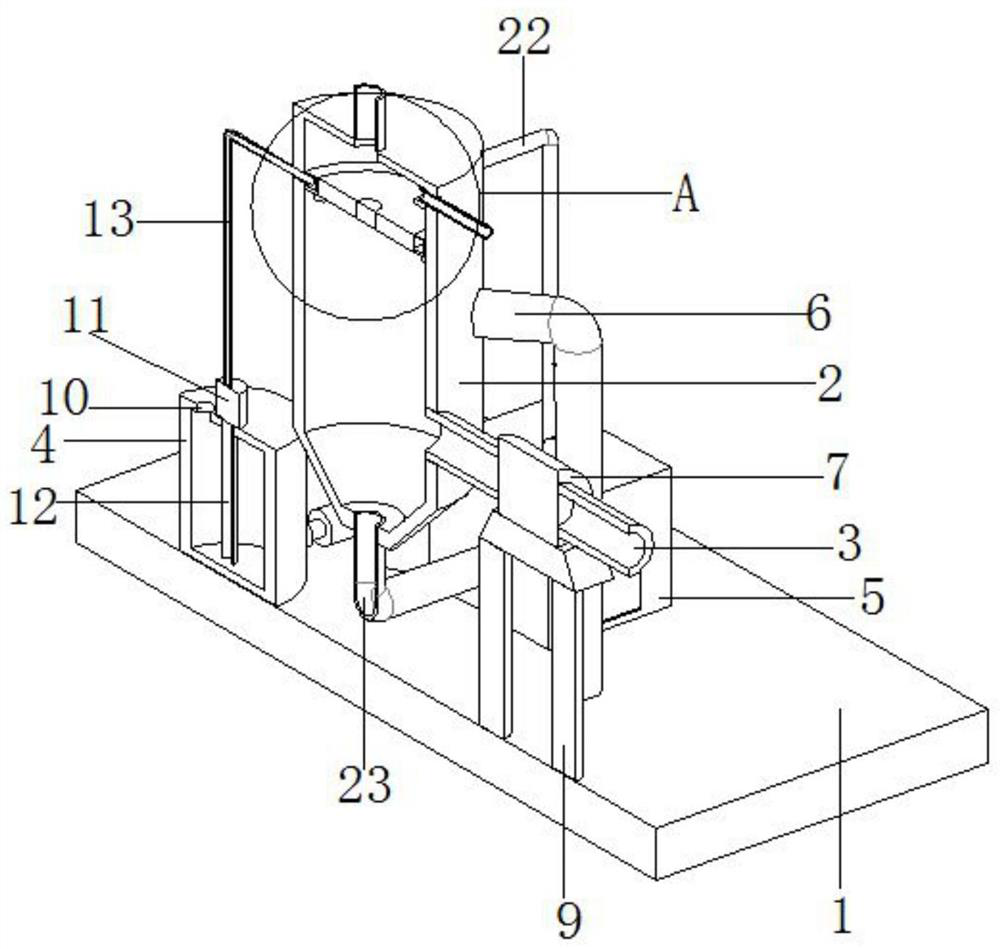

[0033] Such as figure 1 , figure 2 with Figure 7 As shown, an energy-saving and environment-friendly limestone-gypsum wet flue gas desulfurization tower includes a base 1, a desulfurization tower 2, a flue gas pipe 3, a limestone slurry tank 4 and an oxidation treatment box 5. The desulfurization tower 2 includes a cylindrical part and In the cone part, the flue gas pipe 3 runs through the upper part of the bottom of the cylinder part, the length of the part where the flue gas pipe 3 runs through the desulfurization tower 2 is equal to the wall thickness of the desulfurization tower 2, and the side wall of the oxidation treatment box 5 is provided with an observation window 36 , the area of the observation window 36 is greater than half of the area of the side wall of the oxidation treatment box 5 where it is located, the end of the flue gas pipe 3 is connected and set through the side wall of the desulfurization tower 2, the limestone slurry tank 4 and the oxidation tr...

Embodiment 2

[0035] Such as image 3 with Figure 4 As shown, embodiment two is a further improvement on embodiment one.

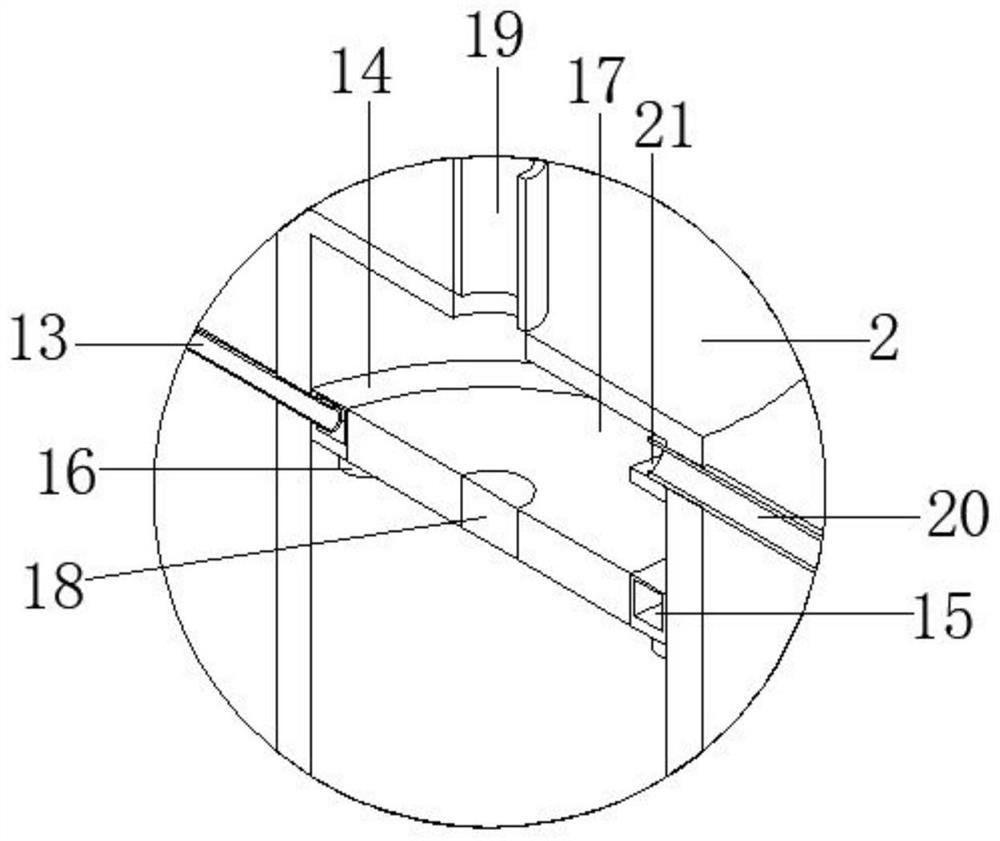

[0036] The inner cavity of the desulfurization tower 2 is fixed with an installation ring plate 14 at the penetrating position of the end of the infusion tube 13. The end of the infusion tube 13 is sealed and penetrates the installation ring plate 14 and is installed deep inside the flow cavity 15. The installation ring plate 14 is installed in the desulfurization tower 2 The inner wall of the cavity is close to the top. The side wall of the installation ring plate 14 and the inner cavity of the desulfurization tower 2 are sealed and fixed. The atomization nozzle 16 is evenly arranged on the bottom of the installation ring plate 14, and the atomization nozzle 16 is connected to the flow cavity 15. A partition 17 is fixed on the inner wall of the installation ring plate 14, and a water-proof and breathable layer 18 is embedded in the center of the partition 17. , the ...

Embodiment 3

[0038] Such as Figure 5 , Image 6 with Figure 8 As shown, embodiment three is a further improvement on embodiment two.

[0039] The center of the bottom end of the desulfurization tower 2 is connected with a delivery pipe 23. The position where the delivery pipe 23 runs through the side wall of the oxidation treatment box 5 is located in the center of the side wall of the oxidation treatment box 5. The end of the delivery pipe 23 and the side wall passing through the oxidation treatment box 5 are located vertical The surface is the same vertical surface, the end of the delivery pipe 23 is connected to the oxidation treatment box 5, and the top of the oxidation treatment box 5 is provided with an oxygen supply blower 24, and the bottom end of the oxygen supply blower 24 is provided with an oxygen supply pipe 25, and the oxygen supply pipe 25 runs through The top of the oxidation treatment box 5 is arranged, and the bottom end of the center line of the side wall of the oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com