Comprehensive treatment device and method for aged resin

A comprehensive treatment and resin technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve problems such as low recovery efficiency, complicated operation, unclear composition separation, etc., to reduce treatment costs and improve treatment Ability to improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

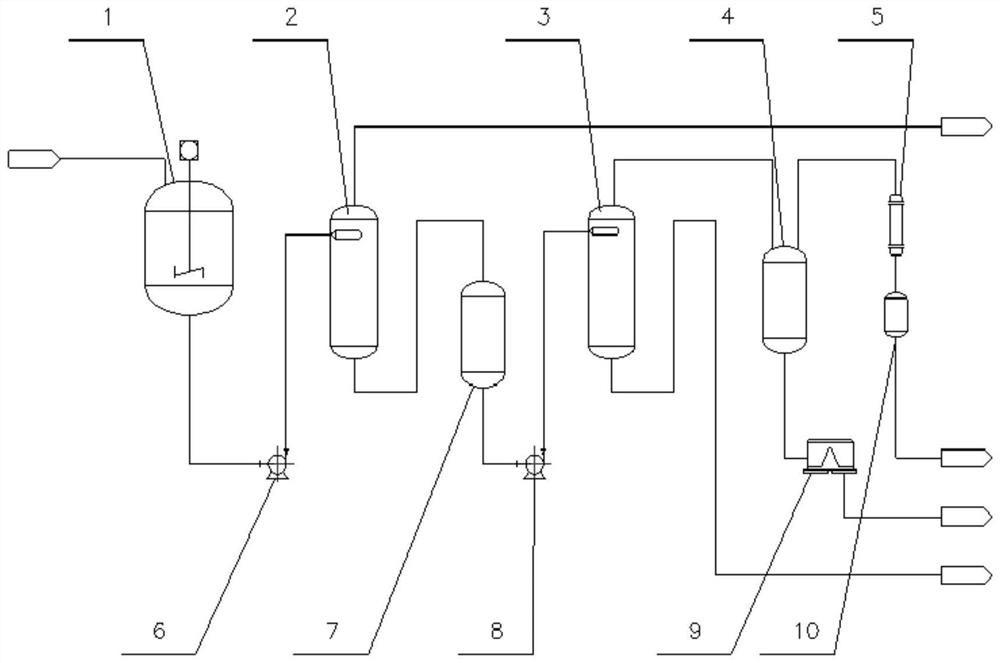

[0048] A method utilizing the comprehensive treatment device to process aged resin, the method comprising the steps of:

[0049] (1) Add back and forth water outside the device into the extraction kettle 1 through the feed port, heat, start stirring, and simultaneously add toluene and the aging resin to be treated to dissolve; wherein, the aging resin: toluene: the mass ratio of water is 1: 2:5; the heating temperature is 70°C, the extraction time is 30min, and the stirring speed is 400r / min.

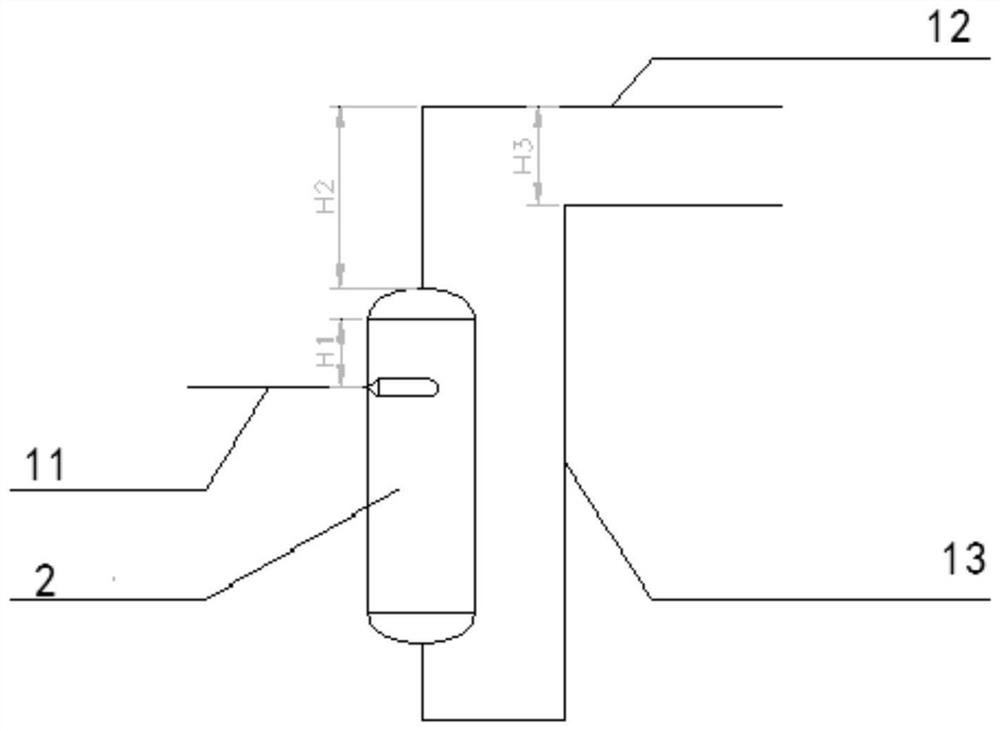

[0050](2) The mixed solution that has been extracted is transported to the phase separator-2 by means of tangential feeding through the material pump-6 for sedimentation and separation for 30 minutes. After the mixture settles and stratifies in the phase separator-2, it is divided into three phases , the upper layer is toluene resin clear liquid, the middle layer is aging resin, and the lower layer is waste water; the upper layer of toluene resin clear liquid passes through the top mate...

Embodiment 2

[0058] A method utilizing the comprehensive treatment device to process aged resin, the method comprising the steps of:

[0059] (1) Add back and forth water outside the device into the extraction kettle 1 through the feed port, heat, start stirring, and simultaneously add toluene and the aging resin to be treated to dissolve; wherein, the aging resin: toluene: the mass ratio of water is 1: 5:10; the heating temperature is 80°C, the extraction time is 200min, and the stirring speed is 300r / min.

[0060] (2) The mixed solution that has been extracted is transported to the phase separator-2 by means of tangential feeding through the material pump-6 for sedimentation and separation for 10 minutes. After the mixture settles and stratifies in the phase separator-2, it is divided into three phases , the upper layer is toluene resin clear liquid, the middle layer is aging resin, and the lower layer is waste water; the upper layer of toluene resin clear liquid passes through the top m...

Embodiment 3

[0068] A method utilizing the comprehensive treatment device to process aged resin, the method comprising the steps of:

[0069] (1) Add back and forth water outside the device into the extraction kettle 1 through the feed port, heat, start stirring, and simultaneously add toluene and the aging resin to be treated to dissolve; wherein, the aging resin: toluene: the mass ratio of water is 1: 4:10; the heating temperature is 90°C, the extraction time is 10min, and the stirring speed is 350r / min.

[0070] (2) The mixed solution that has been extracted is transported to the phase separator-2 by means of tangential feeding through the material pump-6 for sedimentation and separation for 20 minutes. After the mixture settles and stratifies in the phase separator-2, it is divided into three phases , the upper layer is toluene resin clear liquid, the middle layer is aging resin, and the lower layer is waste water; the upper layer of toluene resin clear liquid passes through the top ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com