Deep-hole processing device for semiconductor material

A processing device and semiconductor technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of damage to the drill, loose drill, cracking of the installation base, etc., to reduce rigid meshing friction, prolong the Long service life and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

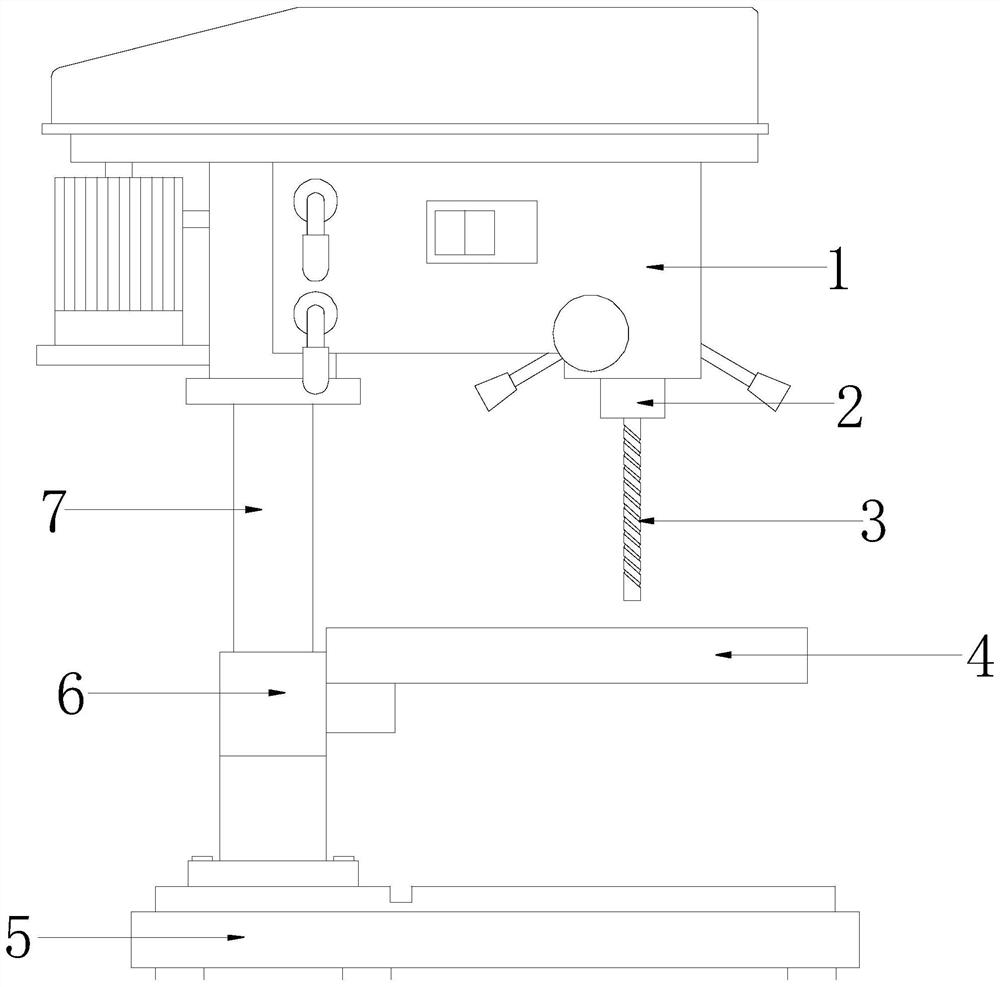

[0037] see Figure 1-5 , the present invention provides a technical scheme of a semiconductor material deep hole processing device: its structure includes an organic body 1, a mounting head 2, a deep hole drill 3, a workbench 4, a base 5, a nut lifting seat 6, a screw rod 7, and the base 5 Connected with the body 1 by a screw 7, the screw 7 is connected with a nut lifting seat 6, and the nut lifting seat 6 is connected to the workbench 4, and the top of the workbench 4 is provided with a deep hole drill 3, and the deep hole drill 3 is connected to the installation head 2, and the installation head 2 is movably connected with the body 1.

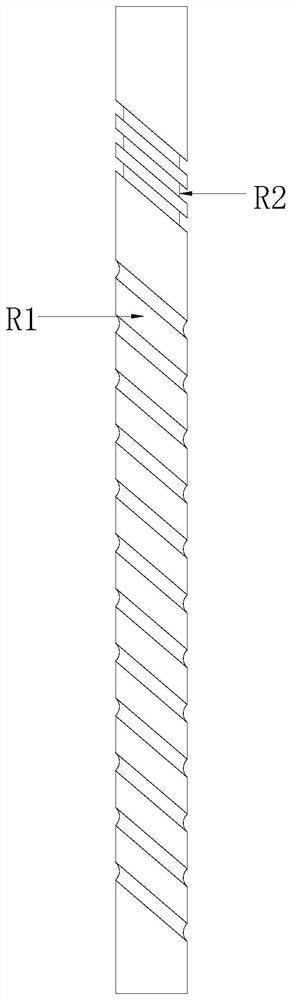

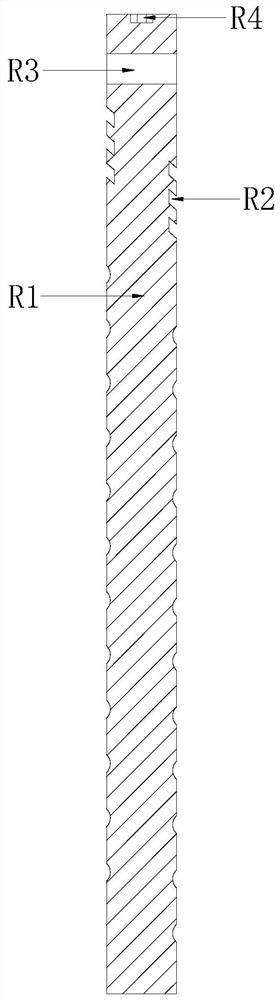

[0038]The deep hole drill bit 3 includes a cutter body R1, an inclined circular groove R2, a card track R3, and a positioning groove R4. The top surface of the cutter body R1 is provided with a positioning groove R4, and the cutter body R1 is also provided with a The card track R3, three inclined circular grooves R2 arranged equidistantly ar...

Embodiment 2

[0041] see Figure 6-7 , the base Q1 includes a base body Q11, an inclined hole Q12, an installation slot Q13, an annular cavity Q14, a through hole Q15, and a positioning column Q16, and the center of the base body Q11 is provided with a cylindrical installation slot Q13, and the installation The slot Q13 is provided with a positioning column Q16 which is an integral structure with the base body Q11, and the base body Q11 is also provided with an annular cavity Q14, and the annular cavity Q14 communicates with the through hole Q15 and the inclined hole Q12, and the inclined hole Q12, through The hole Q15 is arranged on the base body Q11, the rotating assembly Q3 and the power gear set Q5 are located in the annular chamber Q14, the regular triangular hole R41 is matched with the regular triangular prism of the positioning column Q16, and the isosceles triangular hole R42 is matched with the regular triangular prism of the positioning column Q16. The isosceles triangular prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com