Ultrafast laser cutting method and device for transparent materials

A transparent material, ultra-fast laser technology, used in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as processing limitations, and achieve the effect of ensuring quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

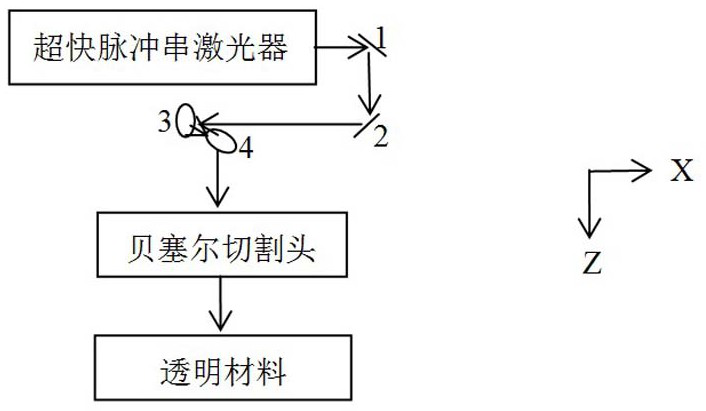

[0030] Example 1: see figure 2 As shown, an ultrafast laser cutting device for transparent materials includes an ultrafast pulse train laser, a light steering component, a Bessel cutting head, and a working platform, and the transparent material to be processed is placed on the working platform.

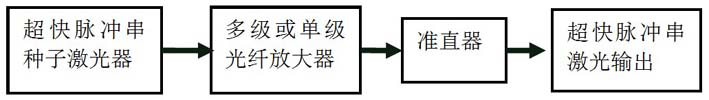

[0031] like figure 1 As shown, in the ultrafast pulse train laser, the ultrafast pulse train seed laser is composed of a semiconductor laser, a multi-stage or single-stage fiber amplifier and a collimator are arranged, and the semiconductor laser provides a pulse train with a wavelength between 1020 nanometers and 1090 nanometers. The seed laser, after being amplified by the fiber amplifier, enters the collimator and outputs ultrafast pulse train laser. Wherein, each laser pulse train includes at least four laser pulses, the pulse width of each laser pulse is less than 60ps, the peak power of the pulse is greater than 1MW, and the time between adjacent laser pulses in the pulse tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com