Graphene multifunctional synthetic fiber and animal-and-plant fiber blending non-woven fabric

A technology of synthetic fibers and fiber blending, applied in the direction of chemical characteristics of fibers, non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor compatibility and poor durability of efficacy, and achieve the effects of good quality, improved physical dispersion and good combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

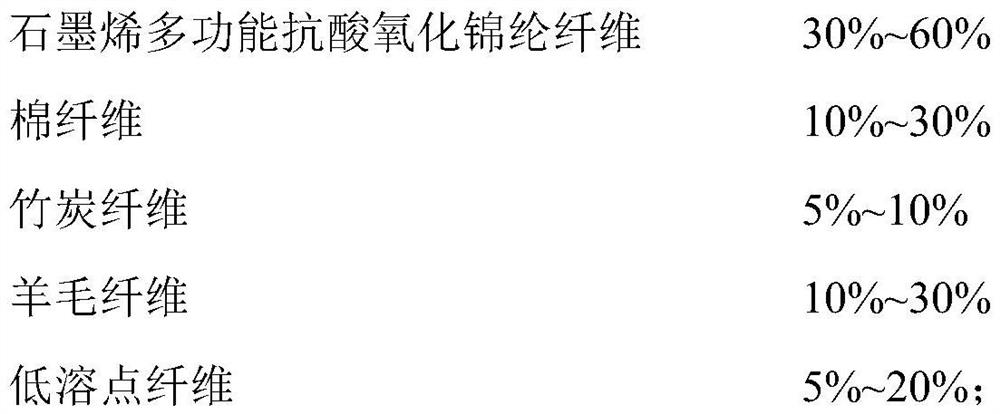

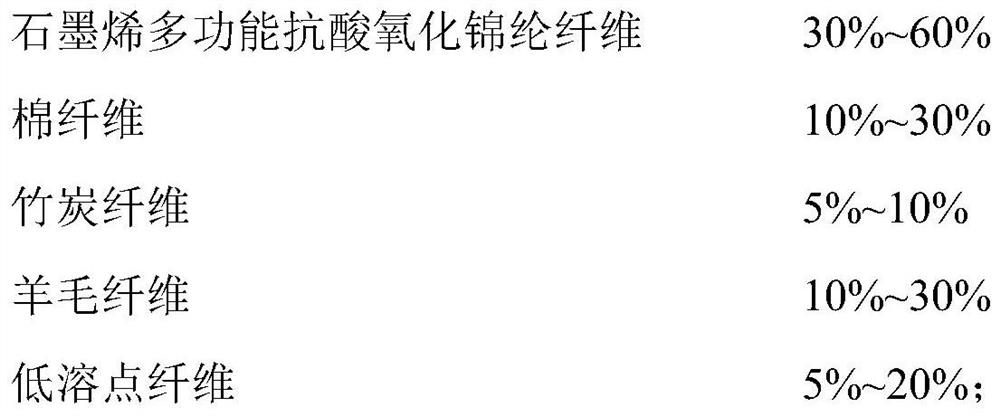

[0031] A kind of graphene multifunctional synthetic fiber and animal and plant fiber blended non-woven fabric of the present embodiment is prepared by the following method:

[0032] (1) Preparation of graphene far-infrared acid-resistant oxidation nylon fiber:

[0033] 28 parts by weight of far-infrared ceramic powder (ground to a particle size of 50-600 nm by high-energy ball milling before use) and 2 parts by weight of silane coupling agent 3-[3-carboxyacrylamide] propyltriethoxysilane in Humidity is 50%~90% air atmosphere and mixes uniformly in the high-speed mixer, then adds 4 parts by weight of carboxylated graphene (commercially purchased, before use, it is 50~600nm through high-energy ball milling to particle size), 65 parts by weight Nylon fiber chips and 1 part by weight of heat stabilizer pentaerythritol stearate are fully stirred and dispersed evenly, and then the mixture is extruded with a twin-screw extruder to obtain graphene far-infrared anti-acid oxidation modi...

Embodiment 2

[0037] A kind of graphene multifunctional synthetic fiber and animal and plant fiber blended non-woven fabric of the present embodiment is prepared by the following method:

[0038] (1) Preparation of Graphene Anion Anti-acid Oxidation Nylon Fiber:

[0039] Mix 18 parts of tourmaline anion powder (before use, through high-energy ball milling to a particle size of 50-600nm) and 2 parts of silane coupling agent 3-[3-carboxyacrylamido]propyltriethoxysilane at a humidity of Mix evenly in a high-speed mixer under an air atmosphere of 50% to 90%, then add 4 parts by weight of carboxylated graphene (commercially purchased, ground to a particle size of 50 to 600nm by high-energy ball milling before use), 75 parts of nylon fiber slices Fully stir and disperse evenly with 1 part of thermal stabilizer pentaerythritol stearate, then extrude the mixture with a twin-screw extruder to obtain graphene anion anti-acid oxidation modified masterbatch. Mix 30 parts by weight of the obtained nega...

Embodiment 3

[0043] A kind of graphene multifunctional synthetic fiber and animal and plant fiber blended non-woven fabric of the present embodiment is prepared by the following method:

[0044] (1) Preparation of graphene antibacterial and acid-resistant oxidized nylon fiber:

[0045] Mix 10 parts of antibacterial nano-zinc oxide and nano-titanium dioxide powder (ground to a particle size of 50-600nm by high-energy ball milling before use) and 1 part of silane coupling agent 3-[3-carboxyallylamide]propyltriethoxy Silane is mixed uniformly in a high-speed mixer under an air atmosphere with a humidity of 50% to 90%, and then 6 parts by weight of carboxylated graphene (commercially purchased, ground to a particle size of 50 to 600nm by high-energy ball milling before use), 82 1 part of nylon fiber chips and 1 part of heat stabilizer pentaerythritol stearate are fully stirred and dispersed evenly, and then the mixture is extruded with a twin-screw extruder to obtain graphene antibacterial and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com