Method for determining VOCs in packaging material through purging and trapping-gas chromatography-mass spectrometry

A purge and trap and gas chromatography technology, which is applied in the field of packaging material detection, can solve the problems of inaccurate chemical characterization, increase of interference factors, loss of substances to be tested, etc., to reduce the risk of false positives, small sample area, and enhanced characterization effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

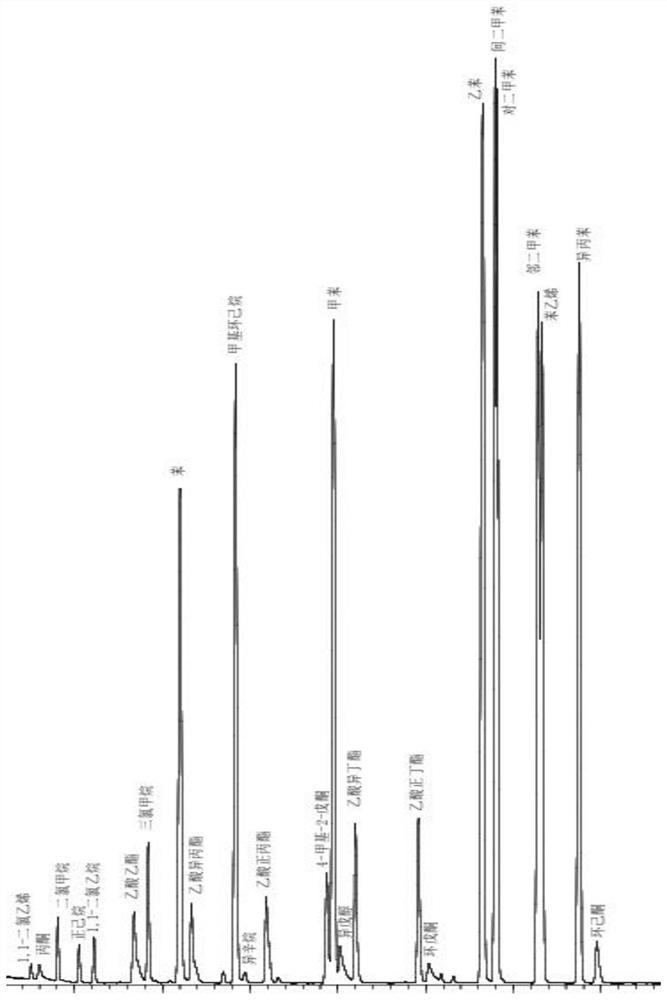

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0024] A method for measuring VOCs in packaging materials by purge and trap-gas chromatography-mass spectrometry, characterized in that: the steps of the method are:

[0025] 1) Sample preparation: sample: food packaging paper and plastic composite film bag; specification model: material: BOPET / PAPER / PE, size (mm): 380×295×0.145; sample description: incoming sample sealed package, sample surface Printed; test content: test food packaging materials VOCs. Cut out 10cm of the densely printed pattern area in the material 2 Sample, place the sample to be tested in a purge bottle, seal it and wait for the test;

[0026] 2) Purge and trap sampling: send the sample in step 1) into the purge and trap injector. The sampling conditions are: the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com