Semiconductor structure and forming method thereof, and semiconductor device

A technology of semiconductor and device area, applied in the field of semiconductor structure and its formation method, and semiconductor device field, can solve the problems of difficult channel and poor control ability of gate structure to channel, and achieve the effect of large etching amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

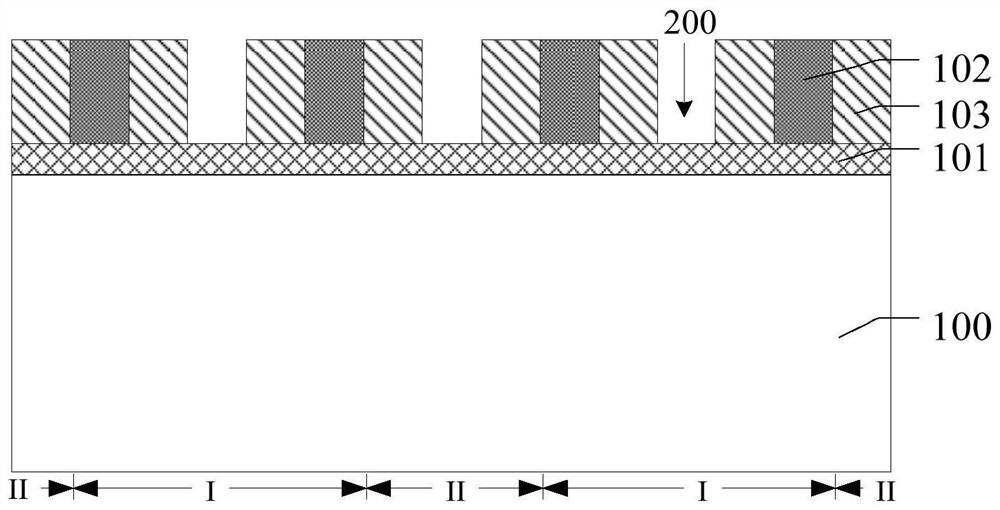

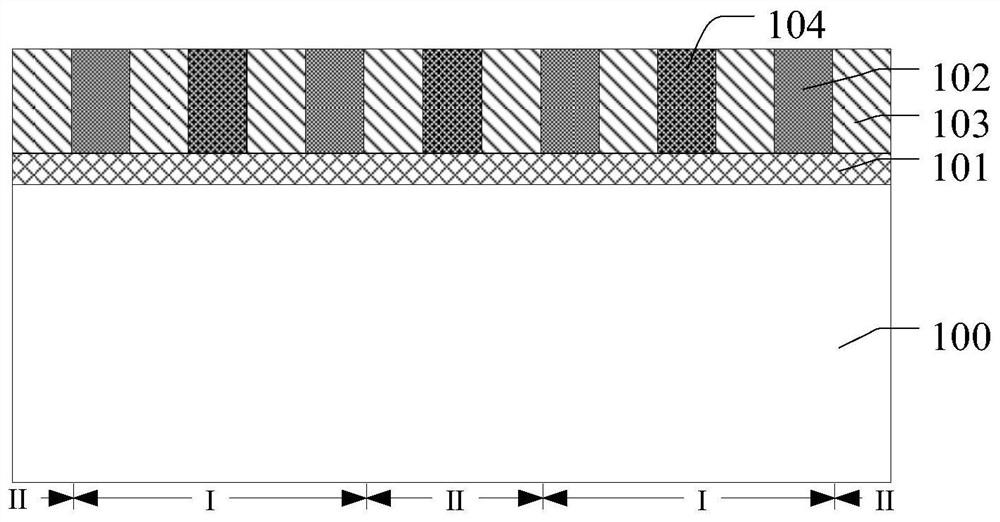

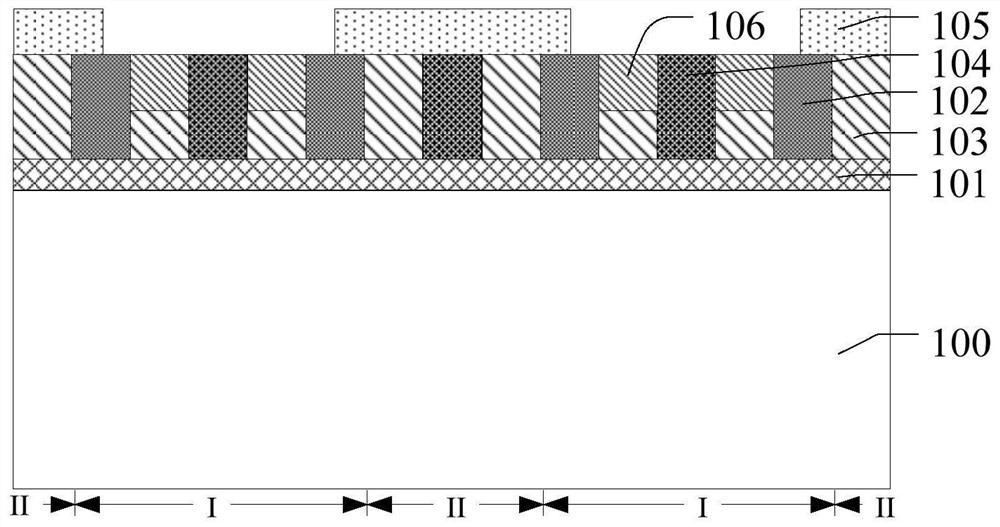

[0014] With the development of technology in the field of semiconductor manufacturing, a new method is urgently needed to form grooves with different depths in the substrate to meet the process requirements.

[0015] In order to solve the technical problem, in the embodiment of the present invention, in the step of etching the etching buffer layer and the partial thickness of the substrate in the same step, the substrate in the first region can only be processed after removing the etching buffer layer. performing etching, the substrate of the second region is etched for a longer period of time and the amount of etching is larger than that of the substrate of the first region, thereby forming a first substrate in the remaining substrate of the first region After the second groove is formed in the remaining substrate of the second region, the depth of the first groove is smaller than the depth of the second groove, so that the groove formed in the substrate can have different de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com