Method for improving charging efficiency of lead-acid storage battery

A lead-acid battery, charging efficiency technology, applied in lead-acid batteries, battery electrodes, secondary batteries, etc., can solve the problems of reduced utilization of active materials, increased internal resistance of batteries, weakened conductivity, etc., to reduce charging losses. , The effect of improving charging efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

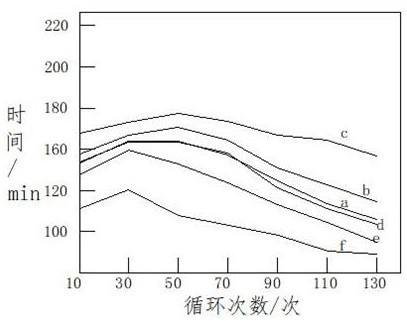

Image

Examples

Embodiment 1

[0066] A method for improving the charging efficiency of lead-acid batteries, preparing composite powder:

[0067] The tin powder and the zinc powder are sintered at high temperature in a carbon dioxide atmosphere to obtain a sintered material, and the mixing mass ratio of the tin powder and the zinc powder is 6:2. The high temperature sintering temperature is 680°C;

[0068] Add selenium powder treated with a coupling agent to the sintered material, grind it in the presence of a dispersant, and then dry it, then heat it at a high temperature in an aerobic atmosphere to obtain a high-temperature composite product. The high-temperature heating The treatment temperature is 250°C, and the selenium powder treated with the coupling agent is as follows: the selenium powder is evenly dispersed in the ethanol solution, heated to 40°C, and then the coupling agent is added to the ethanol solution, while adding While stirring, after the addition is complete, continue to stir for 1 hour,...

Embodiment 2

[0071] A method for improving the charging efficiency of lead-acid batteries, preparing composite powder:

[0072] The tin powder and the zinc powder are sintered at high temperature in a carbon dioxide atmosphere to obtain a sintered material, and the mixing mass ratio of the tin powder and the zinc powder is 10:3. The high temperature sintering temperature is 780°C;

[0073] Add selenium powder treated with a coupling agent to the sintered material, grind it in the presence of a dispersant, and then dry it, then heat it at a high temperature in an aerobic atmosphere to obtain a high-temperature composite product. The high-temperature heating The treatment temperature is 300°C, and the selenium powder treated with the coupling agent is as follows: the selenium powder is evenly dispersed in the ethanol solution, heated to 45°C, and then the coupling agent is added to the ethanol solution, while adding While stirring, after the addition is complete, continue to stir for 1 hour...

Embodiment 3

[0076] A method for improving the charging efficiency of lead-acid batteries, preparing composite powder:

[0077] The tin powder and the zinc powder are sintered at high temperature in a carbon dioxide atmosphere to obtain a sintered material, and the mixing mass ratio of the tin powder and the zinc powder is 8:2.5. The high temperature sintering temperature is 720°C;

[0078] Add selenium powder treated with a coupling agent to the sintered material, grind it in the presence of a dispersant, and then dry it, then heat it at a high temperature in an aerobic atmosphere to obtain a high-temperature composite product. The high-temperature heating The treatment temperature is 280°C, and the selenium powder treated with the coupling agent is as follows: the selenium powder is evenly dispersed in the ethanol solution, heated to 42°C, and then the coupling agent is added to the ethanol solution, while adding While stirring, after the addition is complete, continue to stir for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com