Adjustable liquid metal antenna array based on magnetic control voltage transformation technology

A liquid metal, antenna array technology, applied in the direction of antenna array, antenna, antenna coupling, etc., can solve the problems of the influence of the array signal, can only be used vertically, and the influence is very huge, to reduce electromagnetic interference, realize automatic control, and can Strong control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

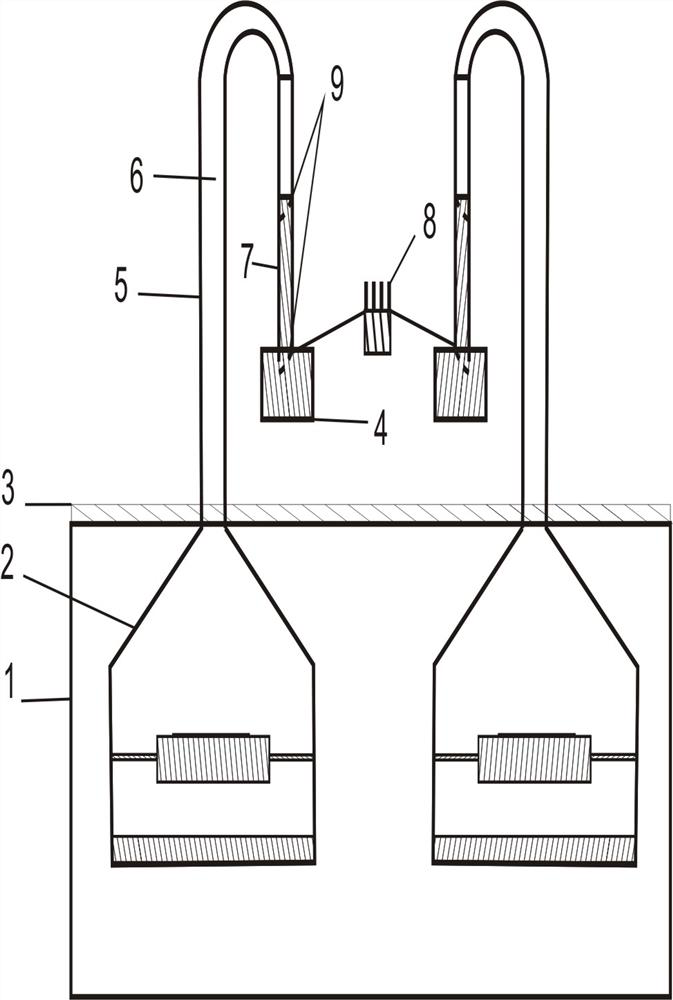

[0027] Such as figure 2 As shown in the schematic diagram of the magnetic control device of the present invention, the magnetic control device 2 comprises an air chamber 2-1, a rubber valve 2-2, an electromagnet 2-3, a magnet 2-4 and a control circuit 2-5, and the magnetic control device 2 passes through the pipeline 5 communicates with the liquid metal antenna, the upper part of the gas chamber 2-1 is encapsulated, and the lower part communicates with the outside world. The rubber valve 2-2 is a film installed in a circular ring, one end is fixed inside the air chamber 2-1, and the other end is fixed on the electromagnet 2-3. The air chamber is filled with inert gas (such as nitrogen), and the inert gas acts as a protection. Liquid metal is not oxidized, by controlling the current in the electromagnet 2-3, the magnetic force between the electromagnet 2-3 and the magnet 2-4 is controlled, and when the electromagnet 2-3 receives the control signal, it goes down ( or upward) m...

Embodiment 2

[0029] Such as image 3 The schematic diagram of the pipeline cut-off valve structure is shown. Calculate the length of the liquid metal antenna according to the required frequency of the antenna, open the pipeline shut-off valve 9 at both ends of the pipeline, start the magnetic control device 2, and use the air pressure change in the pipeline 5 to adjust the liquid metal 7 in the pipeline. After the regulation is over, close the shut-off valves at both ends of the pipeline. The pipeline shut-off valve 9 and the magnetic control device 2 are turned on or off through the control circuit. In order to avoid the influence of the pipeline shut-off valve 9 on the antenna, it is necessary to cut off the liquid metal storage tank 4 in the pipeline. The connection with the liquid metal 7, the cut-off valves 9 at both ends of the pipeline are made of non-conductive materials such as polymers, and the pipeline 5 is made of flexible non-conductive materials. The liquid metal antenna and ...

Embodiment 3

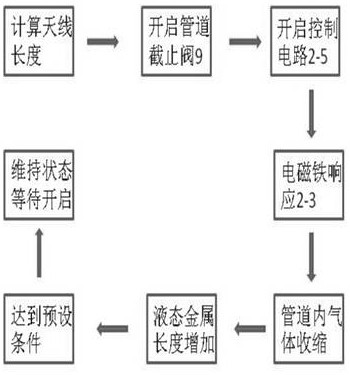

[0031] Such as Figure 4 The workflow diagram of the control module shown is based on the control method of the liquid metal regulated array, including the following steps:

[0032] Calculate the required length of the liquid metal antenna; open the pipeline stop valve 9 through the control circuit 2-5; open the magnetic control device 2, the electromagnet 2-3 attracts the magnet 2-4, and the length of the liquid metal 7 changes under the action of gas pressure , to reach the desired antenna length. Close the magnetic control device 2, close the upper and lower pipeline stop valves 9, and complete the regulation of the liquid metal antenna array. The inert gas effectively prevents the oxidation of the liquid metal 7; the system is highly adjustable and can realize automatic control of large-scale antenna arrays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com