Grounding grid system construction method

A construction method and grounding grid technology, applied in the field of grounding grid system construction, can solve the problems that the grounding grid cannot take into account corrosion resistance, current dissipation effect and heat dissipation effect, and achieve good heat dissipation effect, large surface area and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A method for constructing a grounding grid system, comprising the following steps:

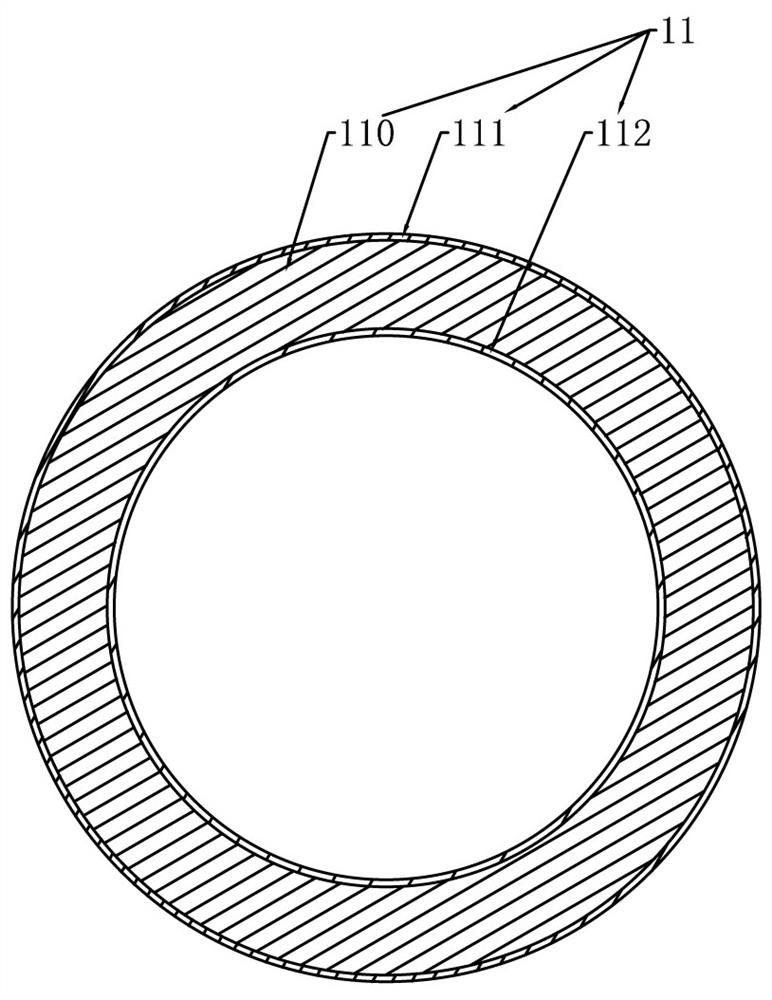

[0040] Buried vertical ground electrodes, figure 1 A vertical grounding electrode is shown, the conductor part of the vertical grounding electrode is composed of a first conductor 11, the first conductor 11 is a hollow pure aluminum conductor or a hollow aluminum alloy conductor, the cross section of the first conductor 11 is circular, The outer diameter of the ring is 40 mm to 50 mm, the wall thickness of the ring is 3.5 mm to 5.0 mm, and the outer surface of the first conductor 11 is treated with a conductive oxidation method to form a conductive protective layer 111;

[0041] Lay horizontal ground electrodes, Figure 5 A horizontal ground electrode is shown, the horizontal ground electrode includes a third conductor 21 and a fourth conductor 20, the third conductor 21 is covered on the surface of the fourth conductor 20 and is non-detachably connected with the fourth c...

Embodiment 2

[0043] Embodiment 2: A method for constructing a grounding grid system, comprising the following steps:

[0044] Buried vertical ground electrodes, figure 1 A vertical grounding electrode is shown, the conductor part of the vertical grounding electrode is composed of a first conductor 11, the first conductor 11 is a hollow pure aluminum conductor or a hollow aluminum alloy conductor, the cross section of the first conductor 11 is circular, The outer diameter of the ring is 40 mm to 50 mm, the wall thickness of the ring is 3.5 mm to 5.0 mm, and the outer surface of the first conductor 11 is treated with a conductive oxidation method to form a conductive protective layer 111;

[0045] Lay horizontal ground electrodes, Figure 4A horizontal ground electrode is shown, the horizontal ground electrode includes a third conductor 21, the third conductor 21 is a solid pure aluminum conductor or a solid pure aluminum alloy conductor, the cross section of the third conductor 21 is circu...

Embodiment 3

[0047] Embodiment 3: A method for constructing a grounding grid system, comprising the following steps:

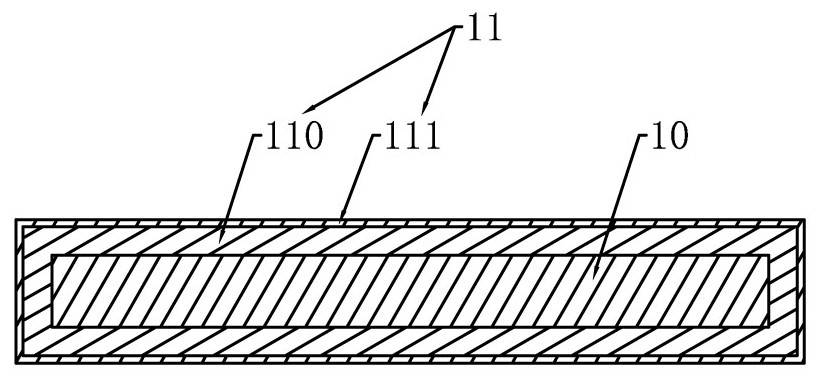

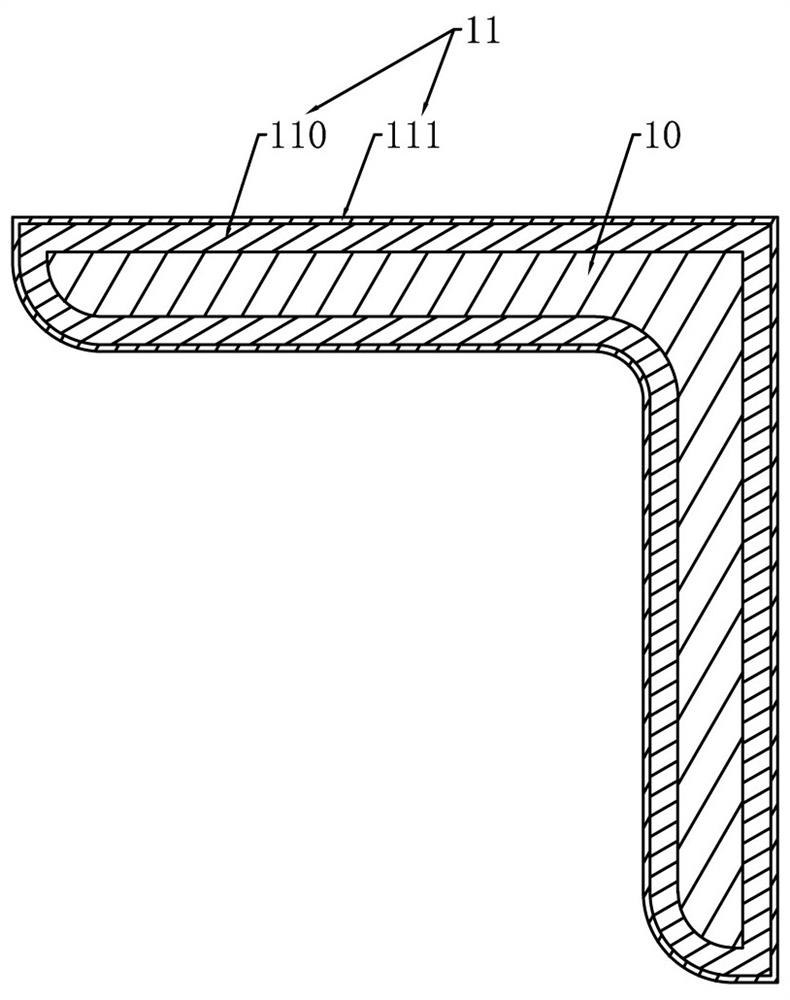

[0048] Buried vertical ground electrodes, figure 2 , image 3 A vertical ground electrode is shown respectively, see figure 2 , the vertical grounding electrode includes a first conductor 11 and a second conductor 10, the first conductor 11 is covered on the surface of the second conductor 10 and is indetachably connected with the second conductor 10, the first conductor 11 is a hollow pure aluminum conductor or a hollow aluminum alloy The second conductor 10 is flat steel, the thickness of the first conductor 11 is 0.2 mm to 0.5 mm, and the outer surface of the first conductor 11 is treated with a conductive oxidation method to form a conductive protective layer 111; see image 3 , the vertical grounding electrode includes a first conductor 11 and a second conductor 10, the first conductor 11 is covered on the surface of the second conductor 10 and is indetachably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com