Full-automatic servo straight edge sealing machine

An edge banding machine, fully automatic technology, used in multi-purpose machinery, forming/shaping machines, special forming/shaping machines, etc., can solve the problems of low degree of automation, danger, slow speed, etc. The effect of high degree of automation and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

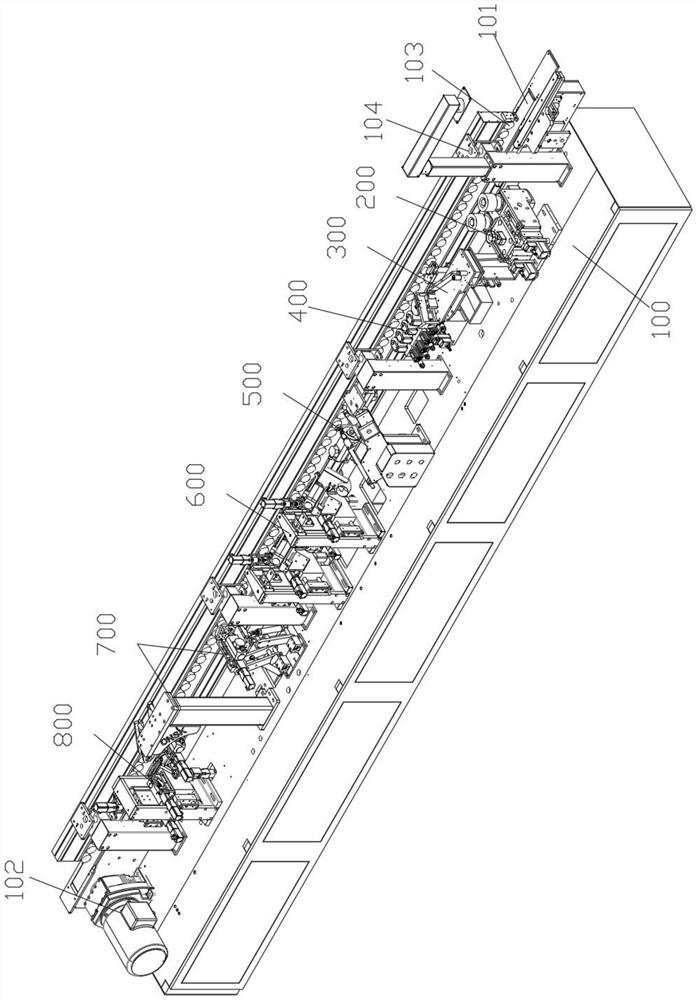

[0042] Such as figure 1 As shown, it includes a workbench 100, a conveyor belt arranged on the workbench, and a PLC control system, and the conveyor belt is used to transport wood; the conveyor belt is driven by a conveyor belt 101 and connected to the conveyor belt. The motor 102 and the uniform array are composed of several conveying rollers 103 correspondingly arranged on the top of the conveyor belt. On the side of the conveyor belt, several groups of pneumatic pressure plates 104 are also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com