Microbial fertilizer fermentation device

A microbial fertilizer and fermentation device technology, applied in fertilization devices, organic fertilizers, organic fertilizer equipment, etc., can solve the problems of continuous use of machines, reduced production efficiency, and uneven mixing, so as to achieve uniform heating, improve work efficiency, and improve The effect of fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

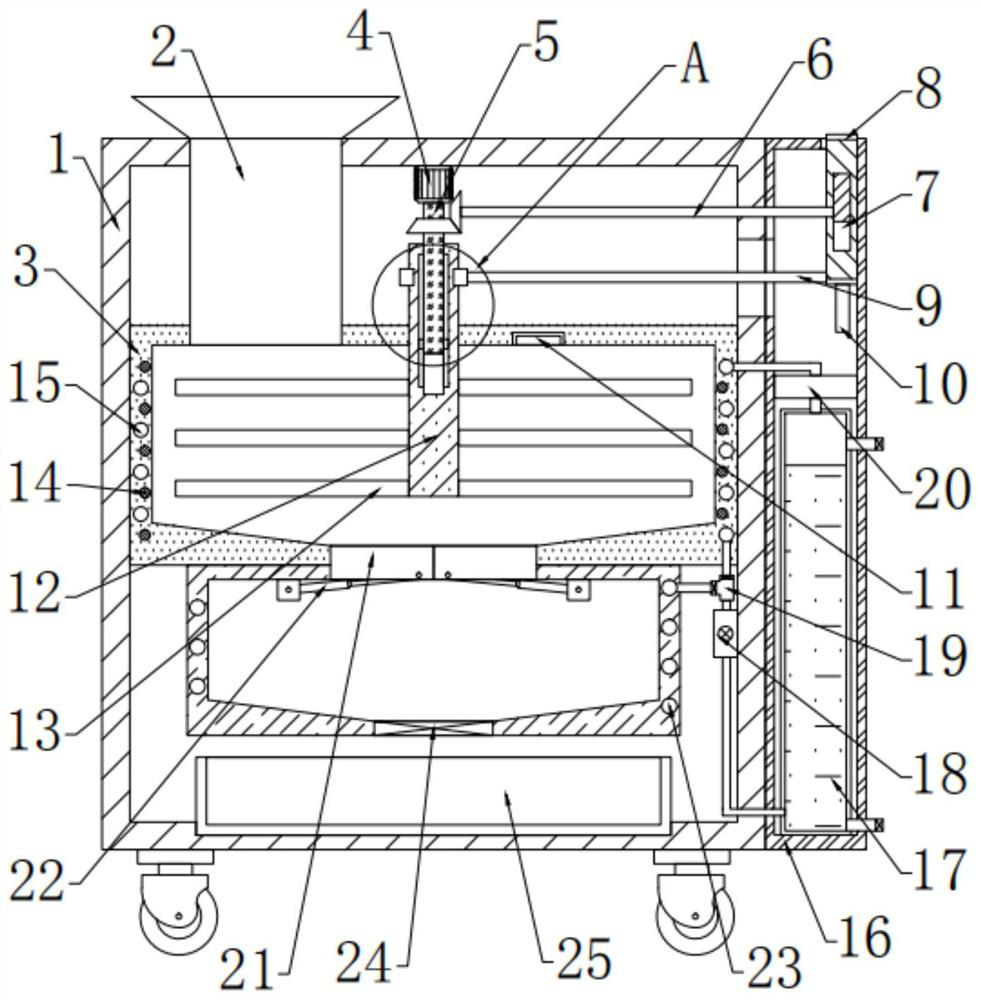

[0024] see Figure 1-3 , in an embodiment of the present invention, a microbial fertilizer fermentation device includes a housing 1, a fermentation tank 3 is fixedly connected to the inside of the housing 1, and a feed pipe 2 is fixedly connected to the top of the fermentation tank 3. A stirring mechanism is arranged inside the fermentation box 3 , and a cooling box is fixedly connected to the bottom of the fermentation box 3 , and both the cooling box and the fermentation box 3 are connected with a temperature adjustment mechanism arranged outside the housing 1 .

Embodiment 2

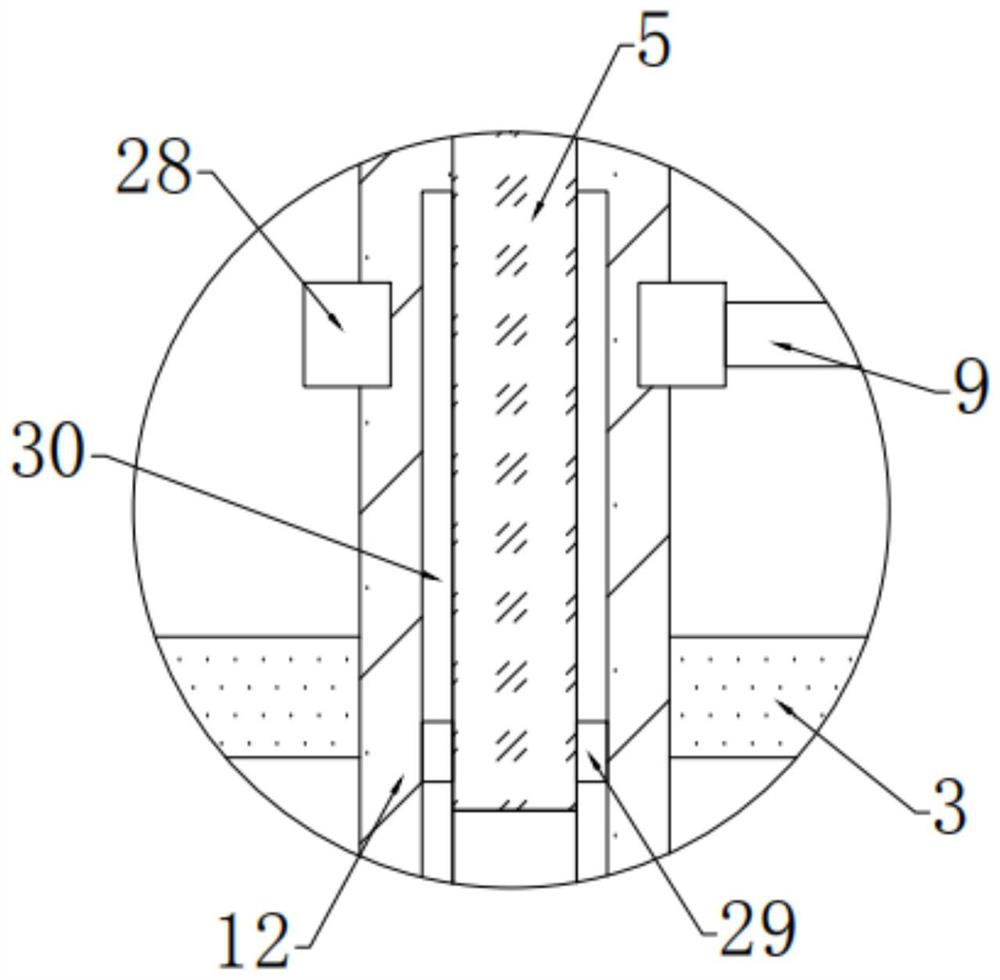

[0026] In this embodiment, the stirring mechanism includes a motor 4 that is bolted to the top of the inner side of the housing 1, the output end of the lower side of the motor 4 is connected to the rotating rod 5, and a movable rod 12 is provided outside the bottom end of the rotating rod 5 The movable rod 12 is fixedly connected with a number of stirring rods 13 on the outside of the inner part of the fermentation box 3, and the outer side of the rotating rod 5 is fixedly connected with a number of limit blocks 29, and the inside of the movable rod 12 is provided with a limit block. 29 is slidingly connected to the limit slot 30, and a transmission mechanism is arranged between the rotating rod 5 and the movable rod 12.

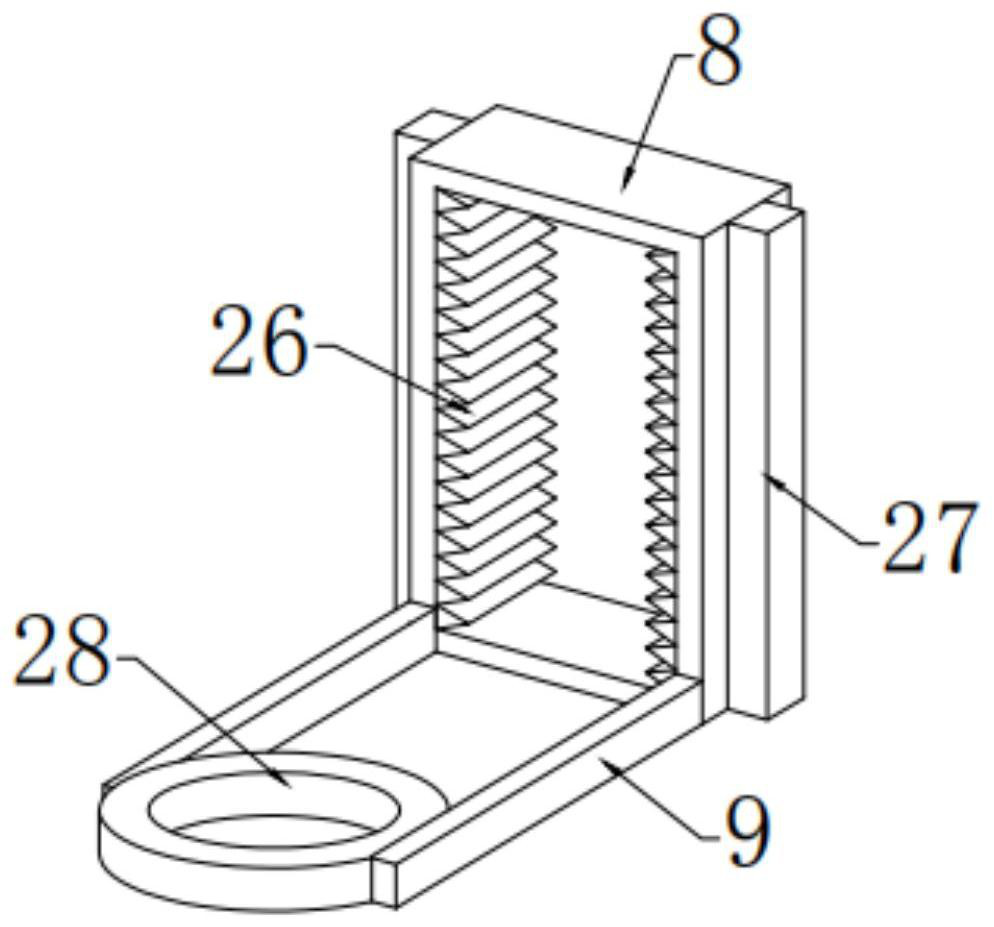

[0027] In this embodiment, the transmission mechanism includes a fixed frame 16 fixedly connected to the right side of the housing 1, the inner side of the fixed frame 16 is slidingly connected with a connecting frame 8, and the front and rear ends of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap