Field portable carbonization furnace for in-situ resource utilization of agricultural waste and graded preparation of biochar

A portable technology for agricultural waste, applied in the field of resource utilization of agricultural waste, can solve problems such as agricultural production troubles, uneven pyrolysis, unaffordable, etc., to improve resource efficiency and environmental protection significance, and improve crushing efficiency , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

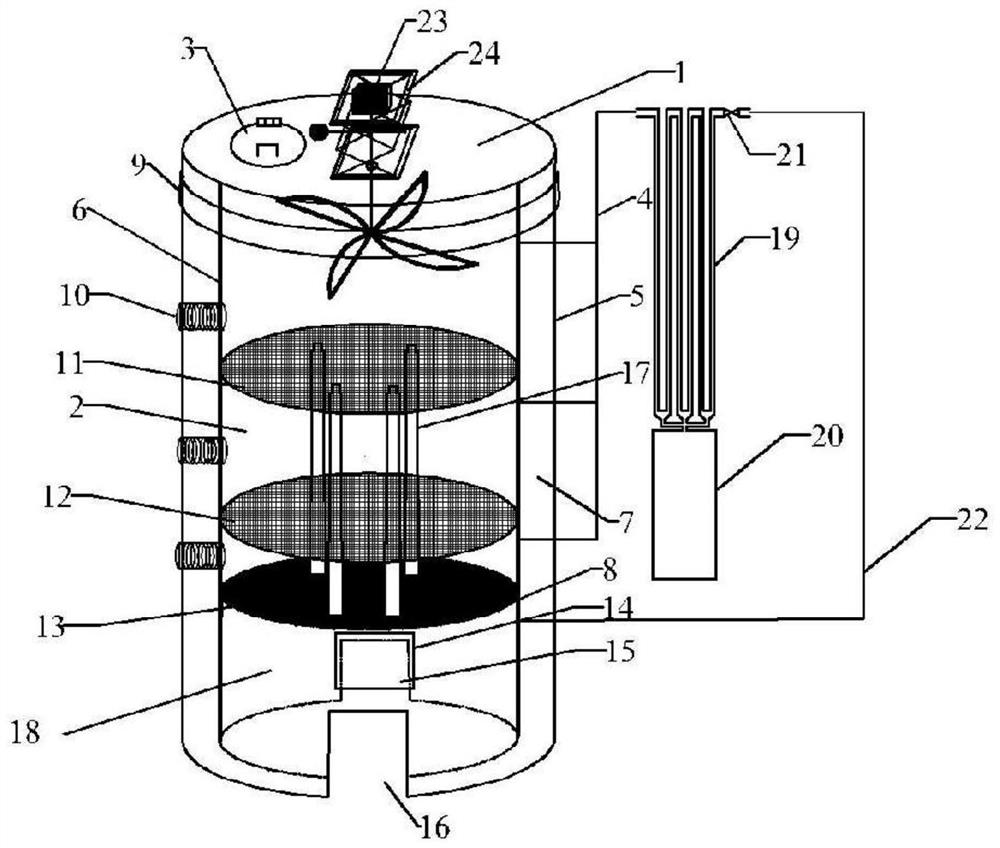

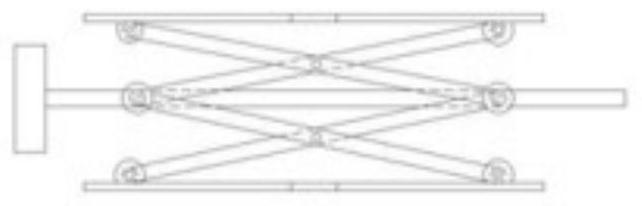

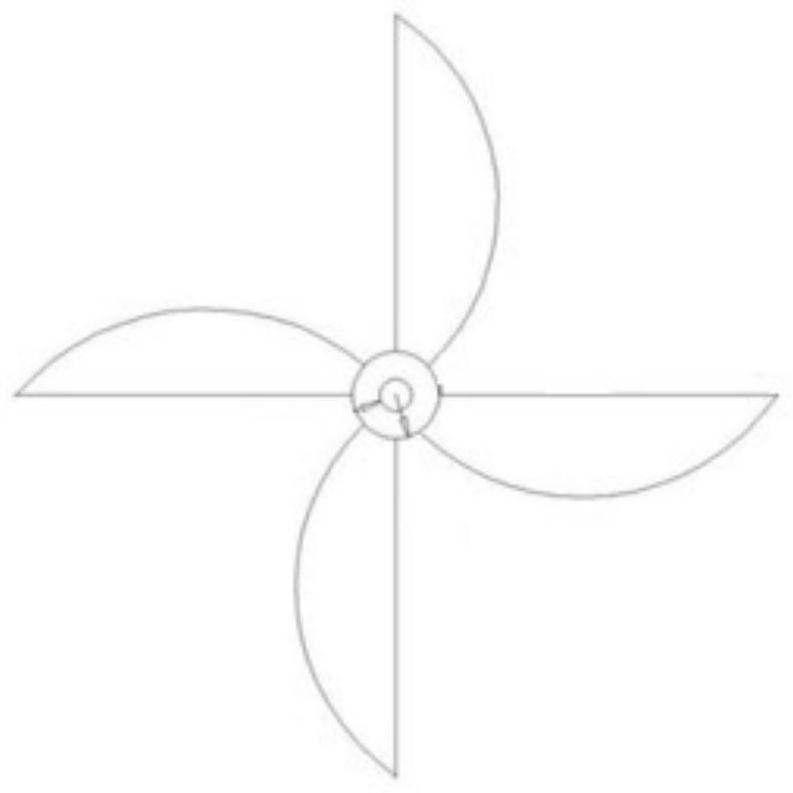

[0035] A field portable carbonization furnace for in-situ resource utilization of agricultural waste to prepare biochar in stages, such as figure 1 , 2 , 3, 4, 5, 6, including cover 1, furnace body 2, material inlet 3, exhaust pipe 4, stainless steel outer layer 5, carbonization area 6, heat insulation layer 7, fixing piece 8, fixing ring 9, A temperature sensor 10, a 5-mesh screen 11, a 10-mesh screen 12, a heating partition 13, an air-limiting slide cover 14, a vent 15, a feed port 16, three heat pipes 17, a heating zone 18, a condensation pipe 19, Exhaust gas collection chamber 20, one-way ventilation valve 21, exhaust gas duct 22, crushing fan 23, lifting frame 24, non-closed fixed half casing 25, insert 26, bolt 27, nut 28;

[0036]The cover 1 is arranged on the top of the furnace body 2, and the cover 1 is fixedly arranged on the top of the furnace body 2 through a fixing ring 9. The fixing ring 9 includes an unclosed fixed semi-sleeve 25, an insert 26, a bolt 27, and a...

Embodiment 2

[0047] A field portable carbonization furnace for in-situ resource utilization of agricultural waste to prepare biochar by classification, including a cover 1, a furnace body 2, a material inlet 3, a smoke exhaust pipe 4, a stainless steel outer layer 5, a carbonization area 6, and a thermal insulation layer 7. Fixed ring 9, a temperature sensor 10, heating partition 13, air-limiting sliding cover 14, vent 15, feed port 16, three heat pipes 17, heating area 18, condensation pipe 19, waste gas collection chamber 20, single Air vent valve 21, exhaust pipe 22, a screen, non-closed fixed semi-sleeve 25, insert 26, bolt 27, nut 28;

[0048] The cover 1 is arranged on the top of the furnace body 2, and the cover 1 is arranged on the top of the furnace body 2 through a fixing ring 9. The fixing ring 9 includes an unclosed fixed semi-sleeve 25, an insert 26, a bolt 27, and a nut 28. The unclosed fixed Both ends of the interface of the half casing 25 are provided with inserts 26, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com