Environmental-friendly energy saving tunnel wax removal kiln

A tunnel kiln, environmental protection and energy saving technology, applied in the direction of furnace, furnace cooling, furnace type, etc., to prevent internal frying, save production costs, and achieve huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

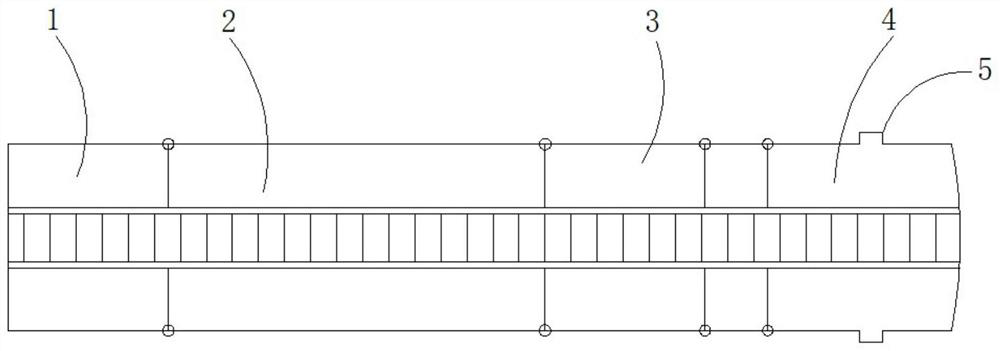

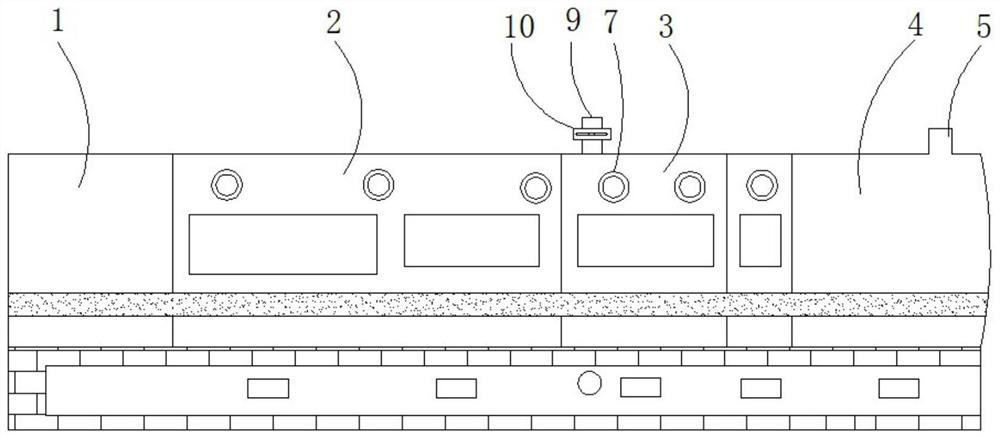

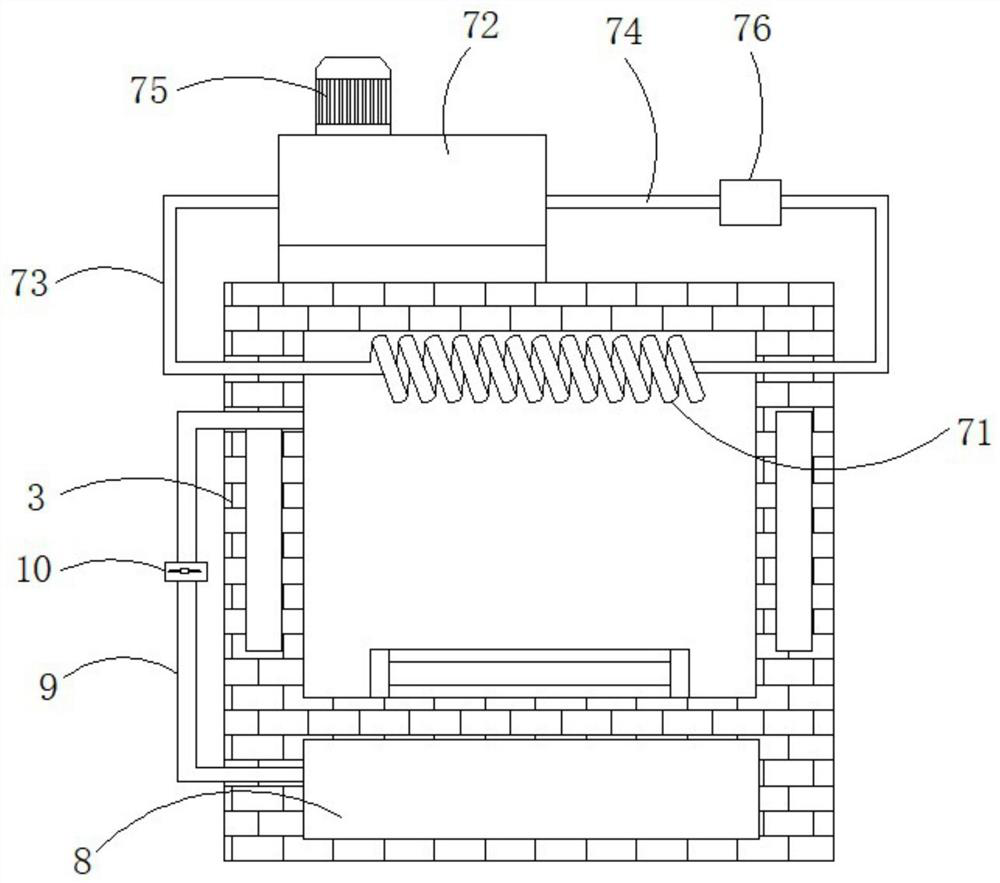

[0039] refer tofigure 1 with figure 2 , an environmental protection and energy-saving tunnel wax discharge kiln, comprising a linearly distributed charging area 1, a preheating tunnel kiln 2, a wax discharge tunnel kiln 3 and a sintering tunnel kiln 4, the preheating tunnel kiln 2 and The product inlet end of the wax discharge tunnel kiln 3 is connected, and the product output end of the sintering tunnel kiln 4 is connected with the wax discharge tunnel kiln 3. The charging area 1, the preheating tunnel kiln 2, and the wax discharge tunnel The kiln 3 and the sintering tunnel kiln 4 share a propulsion assembly, which is a transport piece used in the prior art for the kiln to transport the sintering bowl. The length of the charging area 1 is 3 meters, the length of the preheating tunnel kiln 2 is 7 meters, the length of the wax discharge tunnel kiln 3 is 4.2 meters, and the middle temperature wax discharge area is 1.2 meters. 4 is 11 meters. In this embodiment, the ratio of th...

Embodiment 2

[0048] In this example, refer to Figure 7 , the product outlet of the preheating tunnel kiln 2 is directly connected with the product inlet of the wax discharge tunnel kiln 3, and a corner is set between the preheating tunnel kiln 2 and the wax discharge tunnel kiln 3, which can effectively prevent wax discharge The open flame spreads to the preheating tunnel kiln 2 to keep the preheating temperature of the preheating tunnel kiln 2 stable.

Embodiment 3

[0050] In this example, refer to Figure 8 , the product outlet of the preheating tunnel kiln 2 and the product inlet of the wax discharge tunnel kiln 3 are indirectly connected through the corner tunnel kiln 6, and the preheating tunnel kiln 2 and the wax discharge tunnel kiln 3 are arranged in parallel , It can also effectively prevent the wax discharge open flame from spreading to the preheating tunnel kiln 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com