Refined modeling simulation method for two-dimensional plain woven fiber reinforced composite material

A composite material and fiber-reinforced technology, applied in design optimization/simulation, computer-aided design, special data processing applications, etc., can solve difficult and complex microstructure problems, reduce design and development costs, shorten development cycle, reduce Effect of Actual Number of Experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

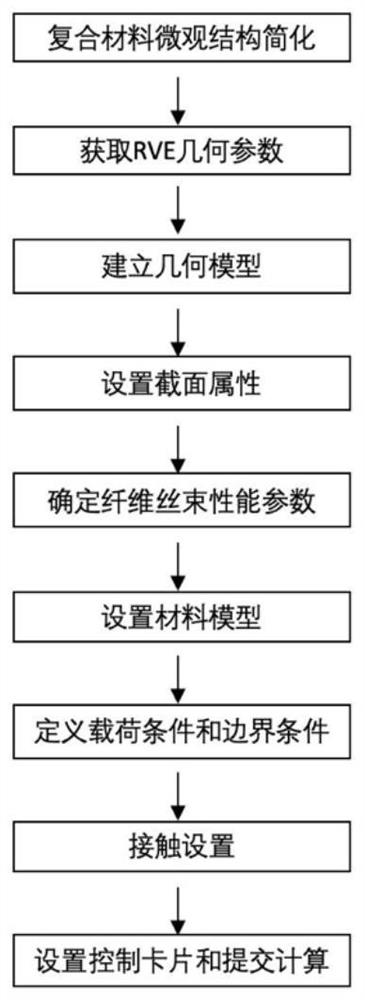

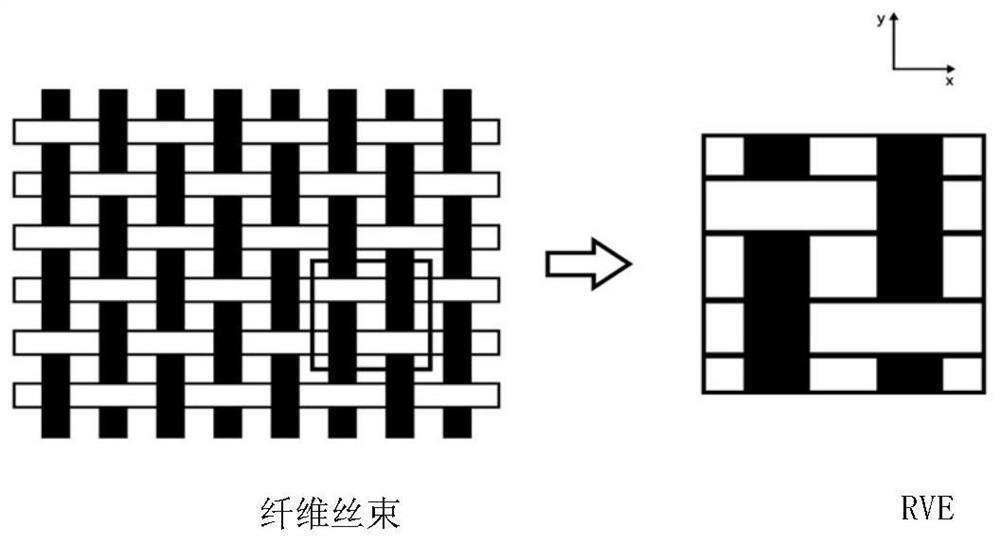

[0103] The following will take the construction of two-dimensional plain weave composite materials as an example to introduce the implementation process of fine modeling of fiber-reinforced composite materials.

[0104] 1. Simplification of the microstructure of the two-dimensional plain weave composite material and acquisition of geometric parameters In the embodiment, the geometric parameters of the RVE model of the two-dimensional plain weave composite material are shown in Table 2.

[0105] Table 2 RVE geometric parameters

[0106]

[0107] II. Setting of material model

[0108] The mechanical parameters of SC-15 epoxy resin and S-2 glass fiber in reference [1] are shown in Table 3, and the settings for each component material in the model are as follows.

[0109] Table 3 Material properties

[0110]

[0111] III. Determination of performance parameters of fiber tow

[0112] As mentioned above, the mechanical properties of the fiber tow in the Y direction (Y t va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com