A continuous production device and method for 1,1,3-trichloropropene

A technology of trichloropropene and production device, which is applied in the field of continuous production device of 1,1,3-trichloropropene, can solve the problems of reduced production efficiency, low yield, reduced reaction conversion rate, etc. The effect of improving the reaction yield and speeding up the circulation flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

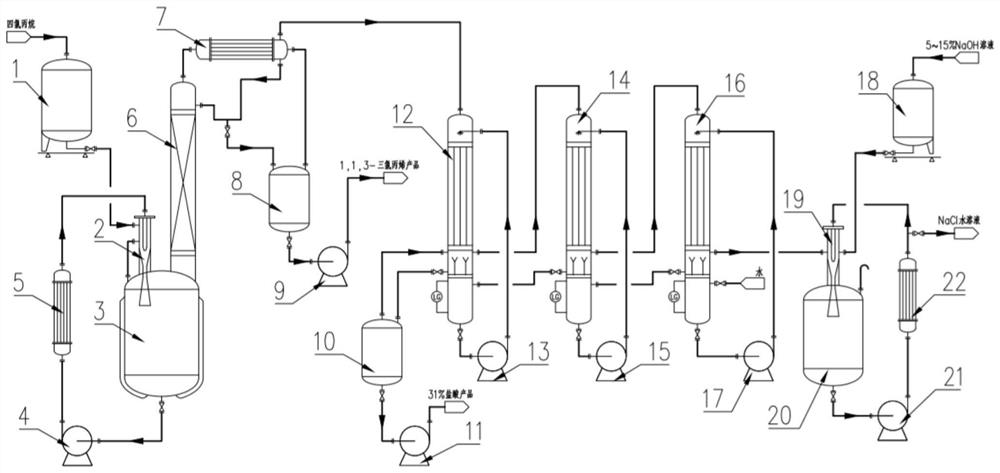

[0043] A continuous production device for 1,1,3-trichloropropene, the device comprises a tetrachloropropane metering tank 1, a venturi jet mixer 2, a reaction distillation still 3, a reaction circulation pump 4, a reaction heater 5, a reaction Rectification tower 6, rectification condenser 7, 1,1,3-trichloropropene receiving tank 8, 1,1,3-trichloropropene product pump 9, hydrochloric acid tank 10, hydrochloric acid product pump 11, primary falling film Absorption tower 12, primary hydrochloric acid pump 13, secondary falling film absorption tower 14, secondary hydrochloric acid pump 15, tertiary falling film absorption tower 16, tertiary hydrochloric acid pump 17, lye metering tank 18, lye vacuum ejector 19 , lye circulating tank 20, vacuum jet pump 21, lye cooler 22;

[0044] Described venturi jet mixer 2 is arranged on the upper end of reactive distillation still 3, and venturi jet mixer 2 suction port and reactive distillation still 3 side tops are communicated by air condu...

Embodiment 2

[0050] A continuous production device for 1,1,3-trichloropropene as described in Example 1, the difference is: the 1,1,3-trichloropropene product pump 9 and the hydrochloric acid product pump 11 are both high The vacuum pump can realize the continuous extraction of 1,1,3-trichloropropene products and hydrochloric acid products. The liquid level gauges are provided in the lower liquid collecting tanks of the falling film absorption towers 12, 14 and 16.

Embodiment 3

[0052] Utilize the method for continuous production of 1,1,3-trichloropropene by the production device described in embodiment 1 or 2, comprising the steps as follows:

[0053] (1) First, the tap water is injected into the liquid collecting tanks of the falling film absorption towers 12, 14 and 16 respectively from the tap water pipeline, and the hydrochloric acid pumps 13, 15 and 17 are turned on to form a circulating absorption circuit. Add a metered 5wt% to 15wt% sodium hydroxide aqueous solution from the alkali solution measuring tank 18 to the alkali solution circulation tank 20, turn on the vacuum jet pump 21, form a circulation neutralization loop, and maintain the negative pressure operating environment of the entire system, the system vacuum The degree is -0.6~-0.95MPa. Add the metered 1,1,1,3-tetrachloropropane from the tetrachloropropane metering tank 1 to the reaction distillation still 3, start the reaction circulation pump 4 to circulate, and form a spray reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com