Application of a graphene oxide nanofiltration membrane under high operating pressure

A technology of operating pressure and graphene, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as limiting the application range of graphene nanofiltration membranes, and achieve the goal of improving water flux and acyl chloride. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

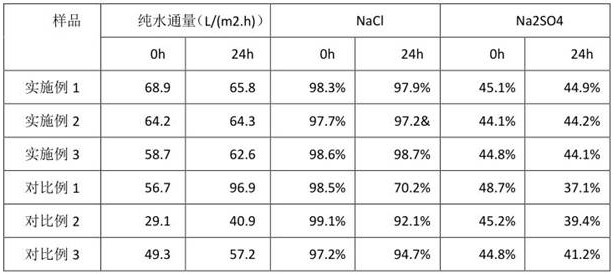

Examples

Embodiment 1

[0022] (1) Preparation of support by blending method

[0023] Mix PVDF, dimethylacetamide, polyethylene glycol, and NaA molecular sieve (silicon-aluminum ratio of 1) according to the mass ratio of 10:120:1:3, stir, and stand for degassing to form a casting solution, and cast it on the glass After scraping the film on the sheet, put it in water to solidify to form a film, soak it in deionized water, dry at 60°C, and then form a film as a support for later use;

[0024] (2) Modification of the acid chloride of the support

[0025] Immerse the surface of the support prepared in step (1) in n-hexane containing 0.5wt% isophthaloyl chloride for 2 hours. After the immersion, remove the surface solution and dry it at 60°C;

[0026] (3) Preparation of graphene oxide nanofiltration membrane

[0027] The modified support prepared in step (2) was immersed in an amino-modified graphene oxide aqueous solution (0.5wt%, adjusted to PH to 11 with NaOH) for 10 minutes, and then impregnated ag...

Embodiment 2

[0029] (1) Preparation of support by blending method

[0030] Mix PVDF, dimethylacetamide, polyethylene glycol, and ZSM-5 molecular sieve (silicon-aluminum ratio of 40) according to the mass ratio of 10:120:1:3, stir, stand for defoaming, and form a casting solution, and After scraping the film on the glass sheet, put it in water to solidify to form a film, soak it in deionized water, dry it at 60°C, and then form a film as a support for later use;

[0031] (2) Modification of the acid chloride of the support

[0032] Immerse the surface of the support prepared in step (1) in n-hexane containing 0.5wt% isophthaloyl chloride for 2 hours. After the immersion, remove the surface solution and dry it at 60°C;

[0033] (3) Preparation of graphene oxide nanofiltration membrane

[0034] The modified support prepared in step (2) was immersed in an amino-modified graphene oxide aqueous solution (0.5wt%, adjusted to PH to 11 with NaOH) for 10 minutes, and then impregnated again in an a...

Embodiment 3

[0036] (1) Preparation of support by blending method

[0037] Mix PVDF, dimethylacetamide, polyethylene glycol, and NaY molecular sieve (silicon-aluminum ratio of 6) according to the mass ratio of 10:120:1:3, stir, and stand for degassing to form a casting solution, and cast it on the glass After scraping the film on the sheet, put it in water to solidify to form a film, soak it in deionized water, dry at 60°C, and then form a film as a support for later use;

[0038] (2) Modification of the acid chloride of the support

[0039] Immerse the surface of the support prepared in step (1) in n-hexane containing 0.5wt% isophthaloyl chloride for 2 hours. After the immersion, remove the surface solution and dry it at 60°C;

[0040] (3) Preparation of graphene oxide nanofiltration membrane

[0041] The modified support prepared in step (2) was immersed in an amino-modified graphene oxide aqueous solution (0.5wt%, adjusted to PH to 11 with NaOH) for 10 minutes, and then impregnated ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com