Fluid control device and fluid control method

A control method and fluid manipulation technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of aerosol pollution, increase system volume and cost, difficulty in quantifying trace fluids, etc., and achieve simplification Operation, avoid contaminant leakage, solve the effect of quantitative difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

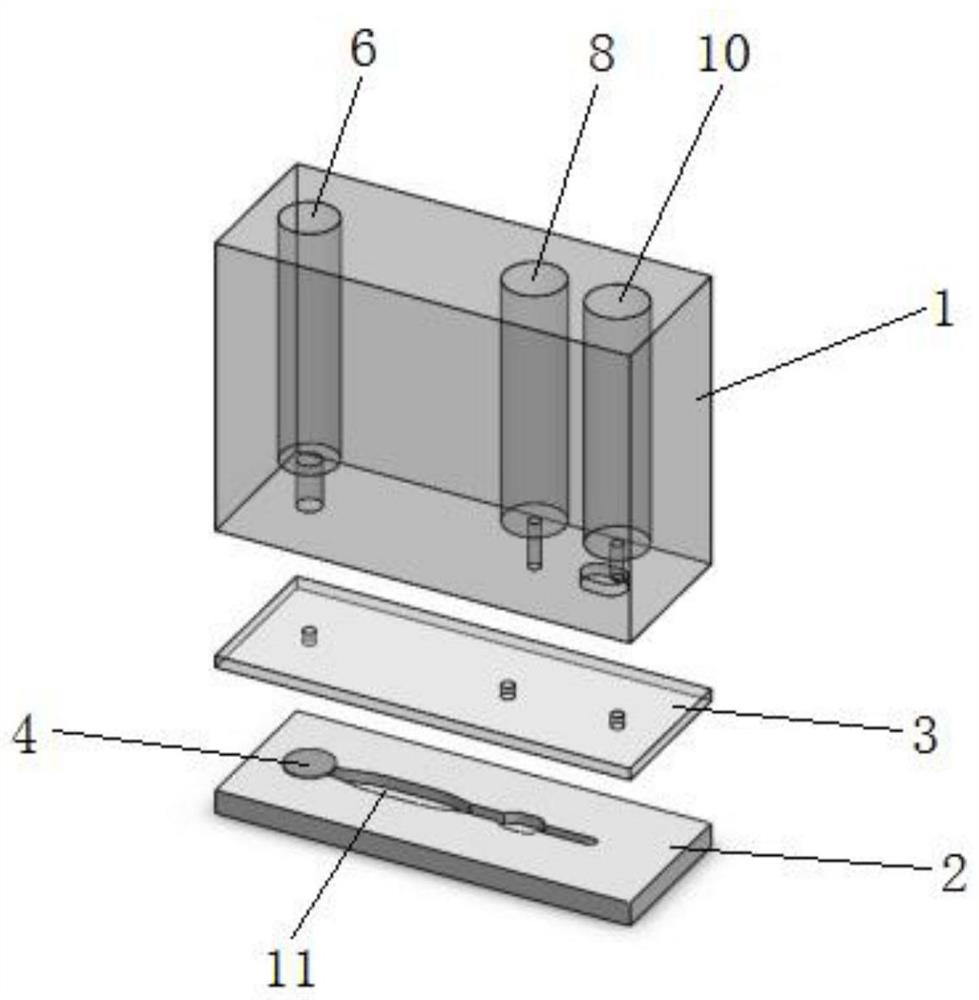

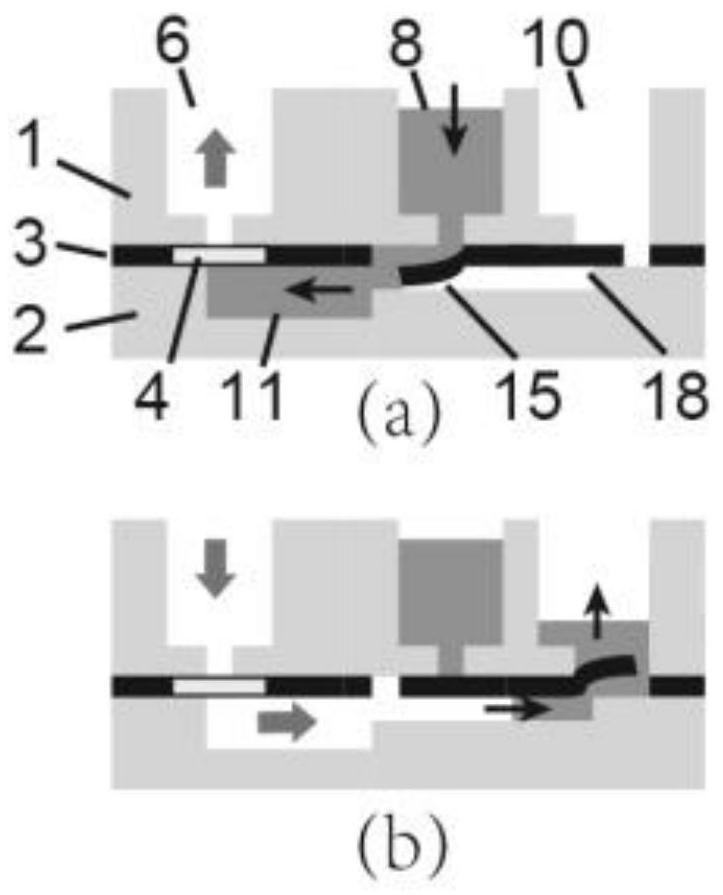

[0030] figure 1 , figure 2 The fluid manipulation device that can realize the quantitative function of microfluid provided according to the first embodiment of the present invention is shown. The fluid manipulation device includes: a cartridge 1, on which a control chamber 6, a reagent chamber 8 and a recovery chamber 10 are formed, and The bottom of the control chamber 6 , the reagent chamber 8 and the recovery chamber 10 are all formed with an opening; the lower chip 2 is formed with a quantitative pool 11 ; the elastic film 3 is used to bond the lower chip 2 to the cartridge 1 The bottom, and the elastic film 3 is provided with the same number of through holes as the bottom openings of the cartridge 1, wherein the opening of the control chamber 6 coincides with the through holes on the elastic film 3, so that the control chamber 6 is communicated with the quantitative pool 11. ; The openings of the reagent chamber 8 and the recovery chamber 10 do not overlap with the thro...

Embodiment 2

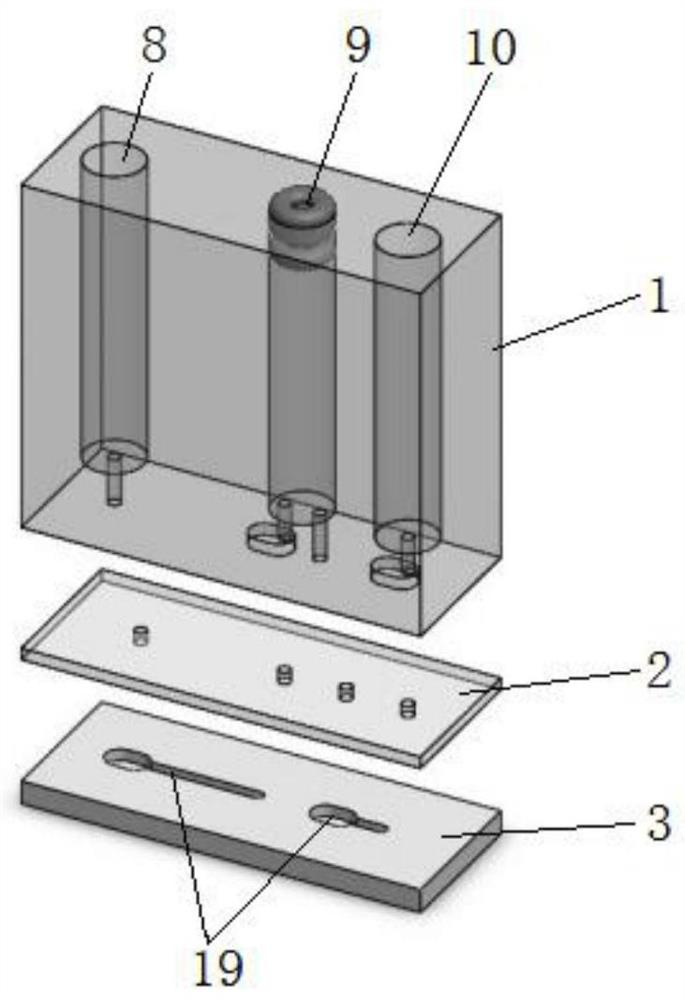

[0037] image 3 , Figure 4 The fluid manipulation device that can realize the one-step fluid mixing and transfer function provided according to the second embodiment of the present invention is shown. The fluid manipulation device includes: a cartridge 1, on which a reagent chamber 8, a mixing chamber 9 and a recovery chamber are formed. chamber 10, and the bottom of the reagent chamber 8 and the recovery chamber 10 is formed with an opening, the mixing chamber 9 is a closed chamber and its bottom is formed with an inlet and an outlet; the lower chip 2 is formed with at least two Disconnected fluid pipeline 19; elastic membrane 3, used to bond the lower chip 2 on the bottom of the cartridge 1, the elastic membrane 3 is provided with the same number of through holes as the bottom opening of the cartridge 1, and the reagent chambers 8, The mixing chamber 9 and the recovery chamber 10 do not coincide with the through holes on the elastic membrane 3, so that between the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com