High-strength polytetrafluoroethylene cable film and preparation method thereof

A technology for preparing polytetrafluoroethylene and film, which is applied in the field of cable film, can solve the problems of easy deformation, poor tensile strength and fracture of microporous polytetrafluoroethylene insulation, and achieve good tensile strength and shrinkage resistance, The production process is environmentally friendly and the production process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

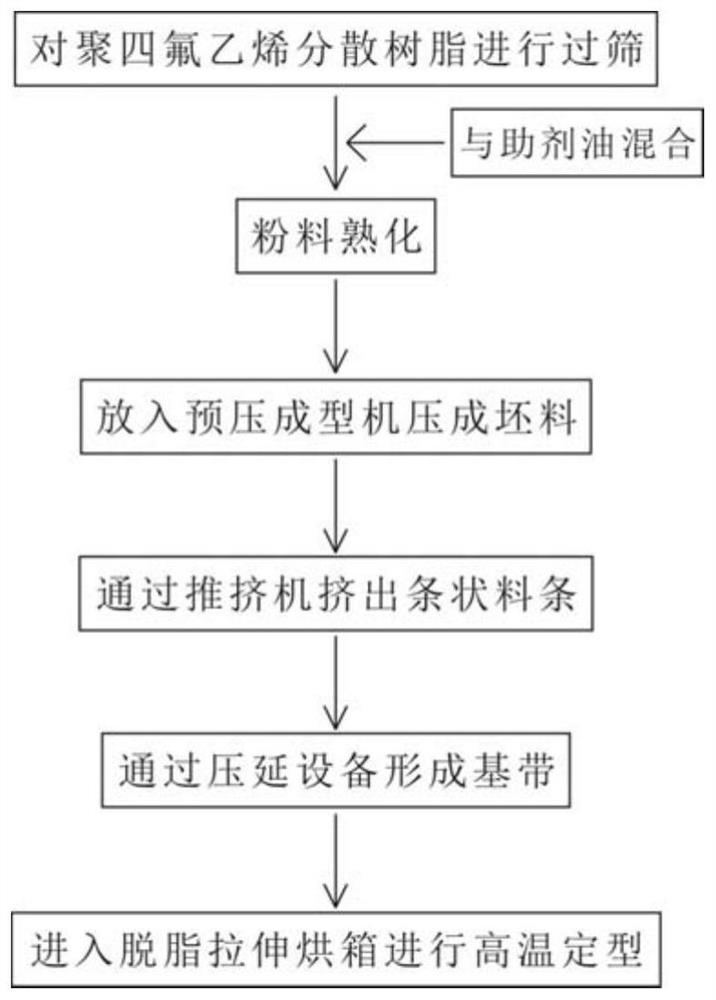

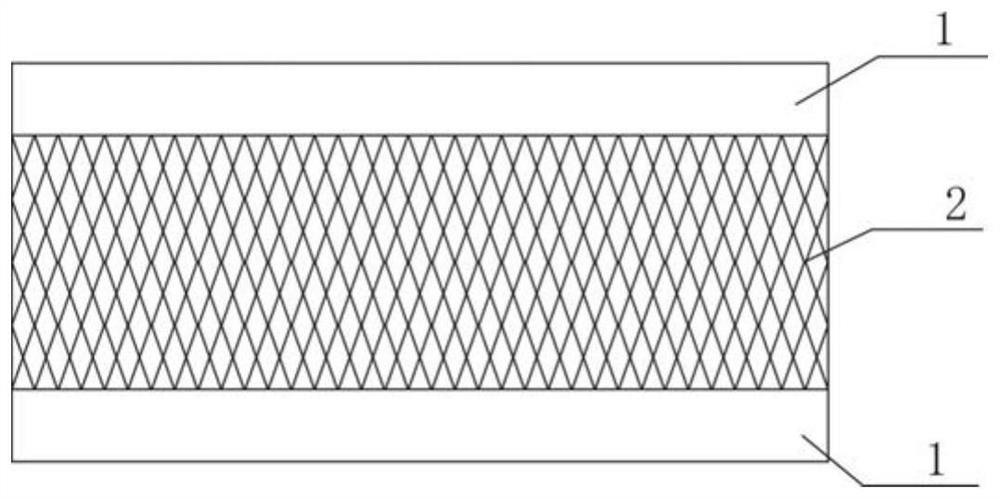

[0018] As shown in the figure, the present invention includes the following steps: a. mixing polytetrafluoroethylene dispersion resin with auxiliary oil and then curing the powder; b. putting the cured powder into a pre-press molding machine and pressing it into a blank; c. The billet is put into a pusher and extruded into a strip; d. the strip is passed through a calendering device to form a base belt; e. the base belt enters a degreasing and stretching oven for high-temperature shaping. The production process of the present invention is simple, and the production process is environmentally friendly. After the film is stretched, its internal structure forms a microporous shape, which reduces its density, ensures lower di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com