A kind of preparation method of high molecular weight zinc hyaluronate

A zinc hyaluronate, high molecular weight technology, applied in the field of biomedicine, can solve the problem of HA-Zn molecular weight decline and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

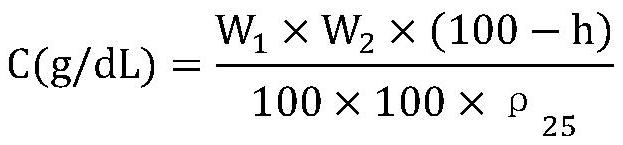

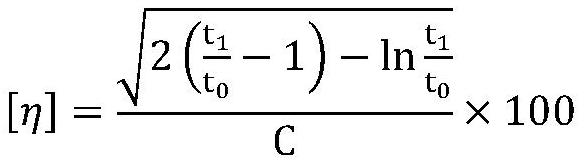

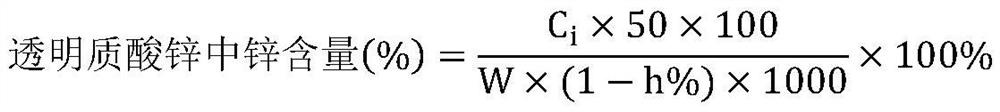

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of high-molecular-weight zinc hyaluronate, which comprises the following steps: adding powdery sodium hyaluronate into a replacement solution for replacement to obtain powdery zinc hyaluronate;

[0027] washing the precipitate with a washing solution;

[0028] The washed precipitate is dehydrated with a dehydrating solution and dried in vacuum to obtain high molecular weight zinc hyaluronate powder.

[0029] In a specific embodiment, the molecular weight of the sodium hyaluronate is greater than or equal to 2 million Da, such as 2 million Da, 2.5 million Da, 3 million Da, 4 million Da, etc.

[0030] In a specific embodiment, the concentration of ethanol in the replacement solution is 70%-85% (v / v), for example, 70%, 72%, 75%, 78%, 80%, 82%, 85% . The zinc ion concentration is 0.15%-1.0% (w / v), for example, 0.15%, 0.24%, 0.30%, 0.40%, 0.50%, 0.60%, 0.72%, 1.0%. Zinc ions can be prepared by adding zinc salts to the replacemen...

Embodiment 1

[0061] (1) Prepare replacement fluid, washing fluid and dehydration fluid. Wherein, the ethanol concentration in the replacement solution was 70% (v / v), the zinc ion concentration was controlled to be 0.48% (w / v), and the pH of the replacement solution was adjusted to 6.0 with glacial acetic acid. The concentration of ethanol in the washing solution was 85% (v / v), and the pH of the washing solution was adjusted to 5.5 with glacial acetic acid. The ethanol concentration in the dehydration solution was 90% (v / v), and the pH of the dehydration solution was adjusted to 5.8 with glacial acetic acid.

[0062] (2) Add sodium hyaluronate with a molecular weight of 2 million Da to the above-mentioned ethanol replacement solution while stirring, continue to stir (replace) for more than 2 hours, stand to separate the supernatant, and replace twice to obtain hyaluronic acid Zinc precipitation.

[0063] (3) Wash the precipitate with the above washing solution for 6 times.

[0064] (4) T...

Embodiment 2-5

[0067] The difference between Examples 2-5 and Example 1 is that the zinc ion concentration, ethanol concentration and corresponding pH in the prepared replacement solution, washing solution and dehydration solution are different, and the corresponding replacement, washing and dehydration times are different, and other The operation steps are the same. The conditions adopted in the specific preparation method are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com