A method for predicting biomass fuel quality and its application

A fuel quality and prediction method technology, applied in the direction of biofuels, analytical materials, measuring devices, etc., can solve the problems of increased energy consumption, reduced density and strength of hydrothermal carbon particles, etc., and achieve the effect of rapid and accurate utilization

Active Publication Date: 2021-03-26

SOUTH CHINA AGRI UNIV

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, after HTC pretreatment, the energy consumption during granulation increased significantly, while the density and strength of hydrothermal charcoal granules decreased compared with untreated biowaste

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

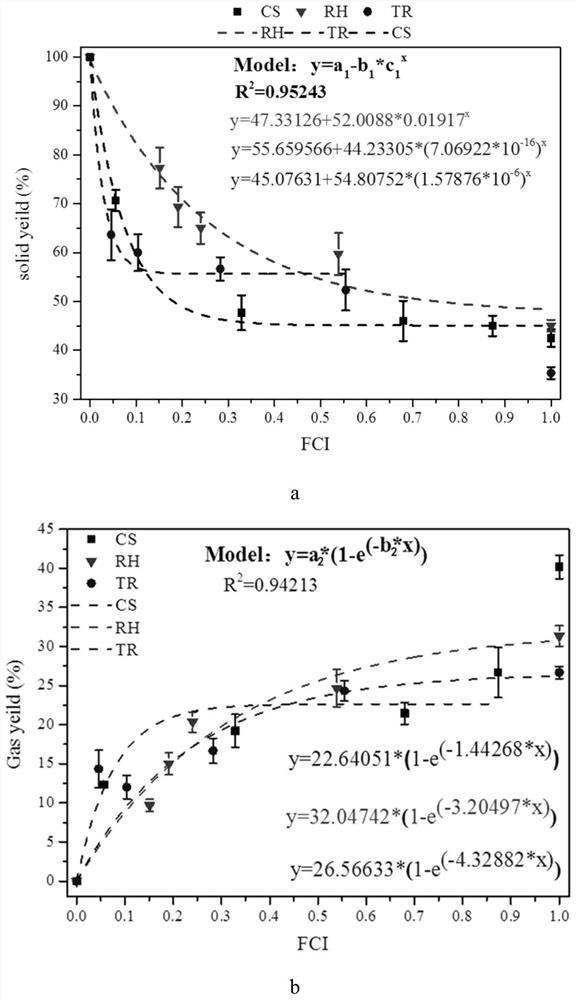

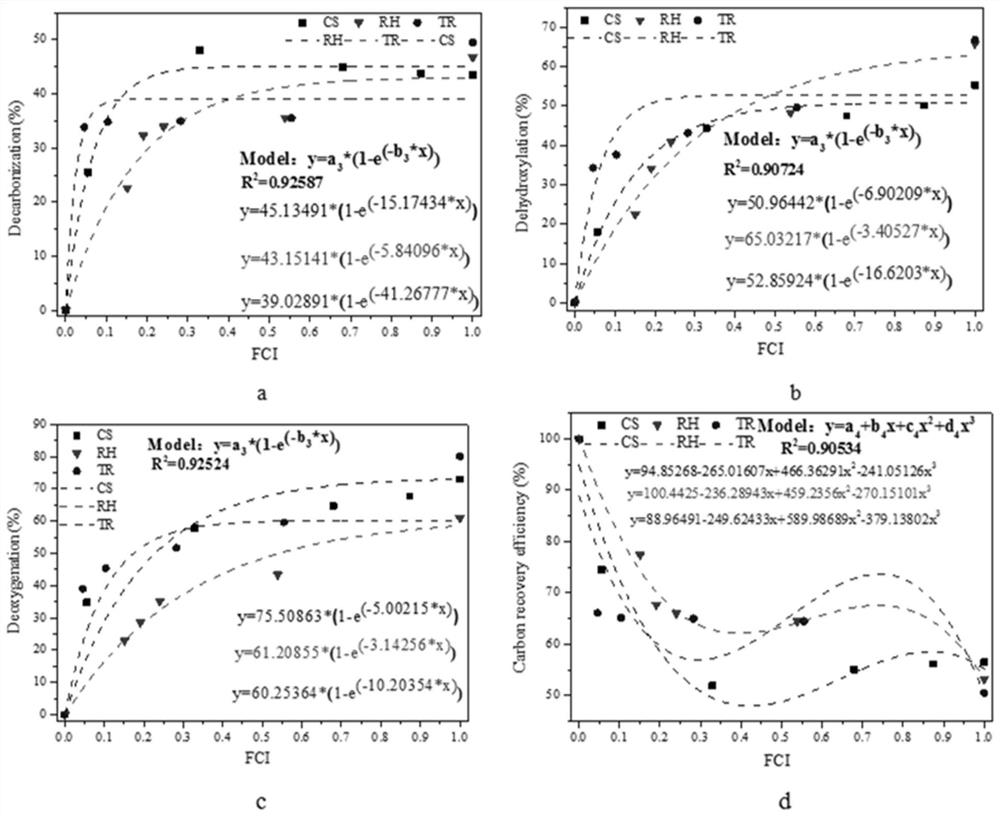

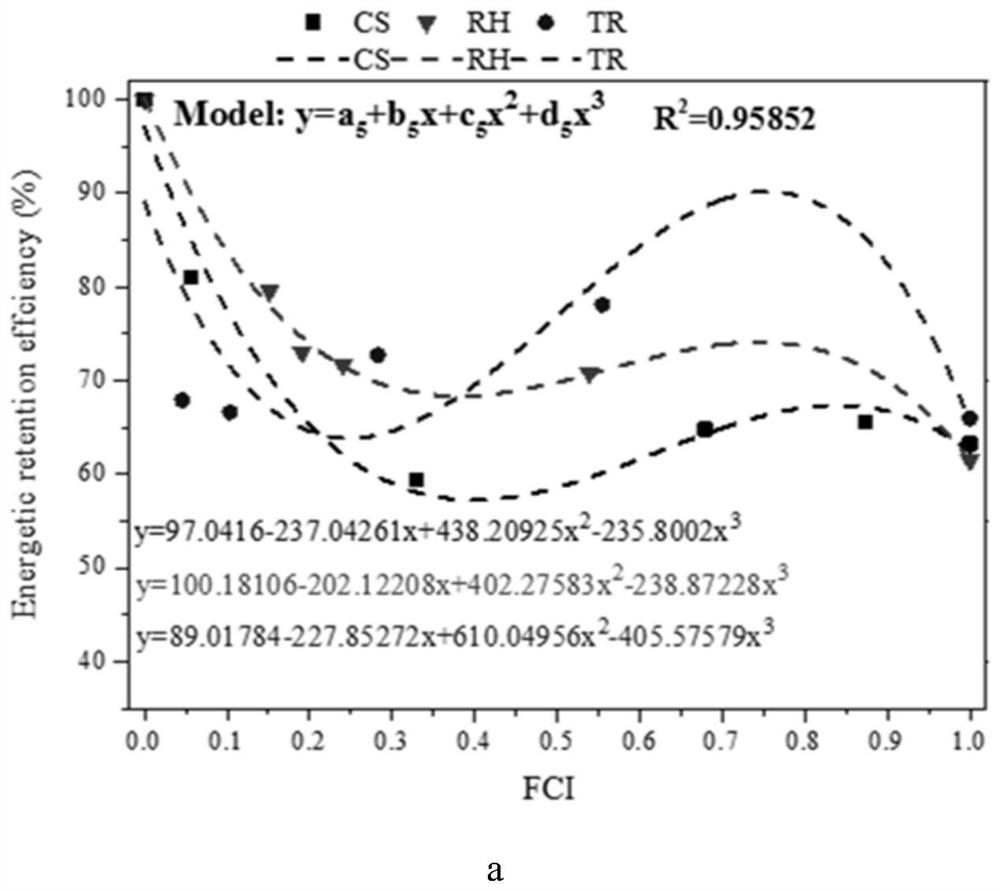

The invention discloses a biomass fuel quality prediction method and applications thereof. The method comprises: (1) mixing biomass and water, and respectively reacting at a temperature t and 250 DEGC to obtain hydrothermal carbon Ct and hydrothermal carbon C250; (2) granulating the hydrothermal carbon Ct, the hydrothermal carbon C250 and the biomass under the same conditions to obtain hydrothermal carbon particles Ct, hydrothermal carbon particles C250 and biomass particles; (3) determining the content FC250 of the fixed carbon of the hydrothermal carbon particles C250, determining the content FCt of the fixed carbon of the hydrothermal carbon particles Ct, determining the content FCm of the fixed carbon of the biomass particles, and establishing a prediction model of a hydrothermal carbonization degree factor FCI; and (4) predicting the fuel quality of the biomass according to the calculated FCI value. According to the invention, by using the method, the biomass energy quality can be rapidly and precisely measured so as to improve the fuel quality and reduce the product cost.

Description

technical field [0001] The invention belongs to the field of biomass resource utilization, in particular to a method for predicting biomass fuel quality and its application. Background technique [0002] Hydrothermal carbonization (HTC) is a pretreatment technology for treating biological waste by autogenous pressure at relatively low temperature (180-250°C). The effectiveness of the HTC is high due to the unimpeded transfer of heat and mass. In particular, high-moisture biological waste such as sewage sludge, kitchen waste, microalgae, and animal manure can be treated by HTC without pre-drying. HTC causes the hydrolysis of cellulose, hemicellulose, and lignin to obtain biochar with lower H / C and O / C ratios, which is beneficial to improve the quality of hydrothermal charcoal as a solid fuel. At the same time, the grindability and hydrophobicity of biomass after HTC are improved, which is beneficial to the storage and transportation of biomass solid fuels. HTC is considere...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N25/00C10B53/02

CPCC10B53/00C10B53/02C10B57/00Y02E50/10

Inventor 许细薇蒋恩臣涂任孙焱吴宇健范旭东王家旻何臻程树朝

Owner SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com