Antirust pigment for cathode electrophoretic paint and slurry preparation method thereof

A cathodic electrophoretic coating and anti-rust pigment technology, applied in the direction of electrophoretic coating, anti-corrosion coating, coating, etc., to achieve the effect of low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

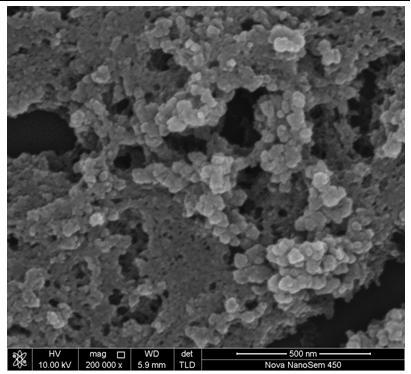

[0029] Weighed 0.03 mol of hexamethylene diamine tetramethylene phosphonic acid and 0.08 mol of cerium nitrate were added into water for dissolution. Use NaOH solution to adjust the pH of the hexamethylenediamine tetramethylene phosphonic acid solution to 7, pour the hexamethylene diamine tetramethylene phosphonic acid and the cerium nitrate solution into a disperser and stir to make them fully mixed. The mixture was left to stand, filtered, and the precipitate was first washed with deionized water and then washed with deionized water to eliminate possible excess inorganic salt ions. Gained precipitation is adjusted to solid content 20% with deionized water, adds 0.1% polyethyleneimine, 0.1% hydroxyethyl cellulose, grinds 1 hour, obtains antirust pigment slurry (gained antirust pigment See in description figure 1 ).

Embodiment 2

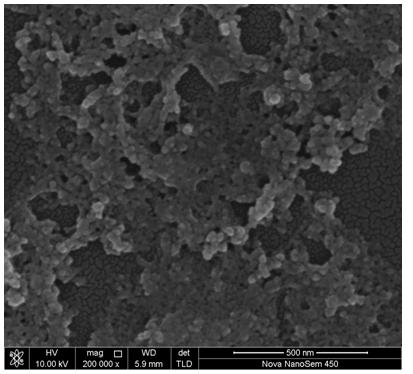

[0031] 1.5 mol of sodium ethylenediamine tetramethylene phosphonate and 4 mol of lanthanum nitrate were weighed and added to water for dissolution. The pH of sodium ethylenediaminetetramethylenephosphonate was adjusted to 4 with dilute hydrochloric acid solution. The pH of the hexamethylenediaminetetramethylenephosphonic acid solution was adjusted to 4 with dilute hydrochloric acid solution, and the sodium ethylenediaminetetramethylenephosphonate and lanthanum chloride solutions were poured into a disperser and stirred to make them fully mixed. The mixture was left to stand, filtered, and the precipitate was first washed with deionized water and then washed with deionized water to eliminate possible excess inorganic salt ions. Gained precipitation is adjusted to solid content 30% with deionized water, adds 0.1% polyethyleneimine, 0.1% hydroxyethyl cellulose, grinds 1 hour, obtains antirust pigment slurry (gained antirust pigment See in description figure 2 ).

Embodiment 3

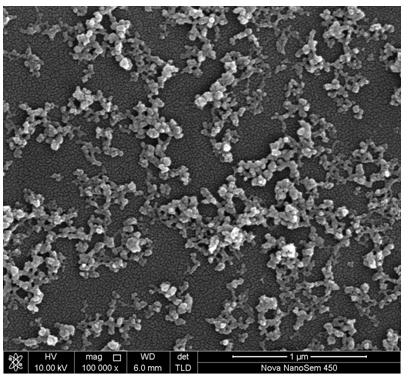

[0033] 0.6 mol of diethylenetriaminepentamethylenephosphonic acid and 1 mol of lanthanum nitrate were weighed and added to water for dissolution. Use KOH solution to adjust the pH of diethylenetriaminepentamethylenephosphonic acid to 5, pour the solution of diethylenetriaminepentamethylenephosphonic acid and lanthanum nitrate into a disperser and stir to make them fully mixed. The mixture was left to stand, filtered, and the precipitate was first washed with deionized water and then washed with deionized water to eliminate possible excess inorganic salt ions. Gained precipitation is adjusted to solid content 30% with deionized water, adds 0.1% polyethyleneimine, 0.1% hydroxyethyl cellulose, grinds 1 hour, obtains antirust pigment slurry (gained antirust pigment See in description image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com