Method for analyzing contents of main elements in low-silicon ferrosilicon by X-ray fluorescence spectrum

A technology of fluorescence spectrum and main elements, applied in the field of analysis, can solve the problems of expensive platinum crucible, increase the cost of inspection and testing, increase the repetitive process, etc., and achieve the effect of meeting the requirements of rapid analysis in production, short inspection cycle and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the details are as follows:

[0026] Embodiments of the present invention provide a method for analyzing the content of main elements in low-silicon ferrosilicon by X-ray fluorescence spectroscopy, comprising the following steps:

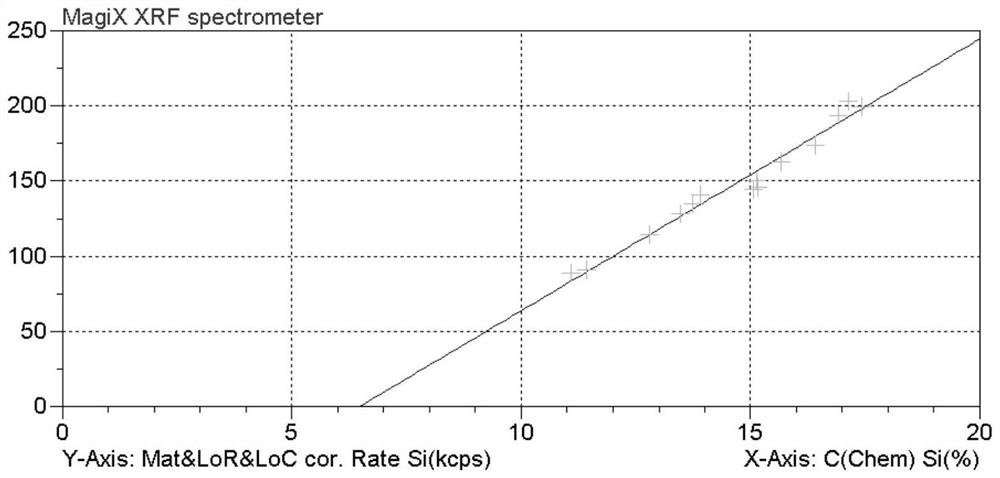

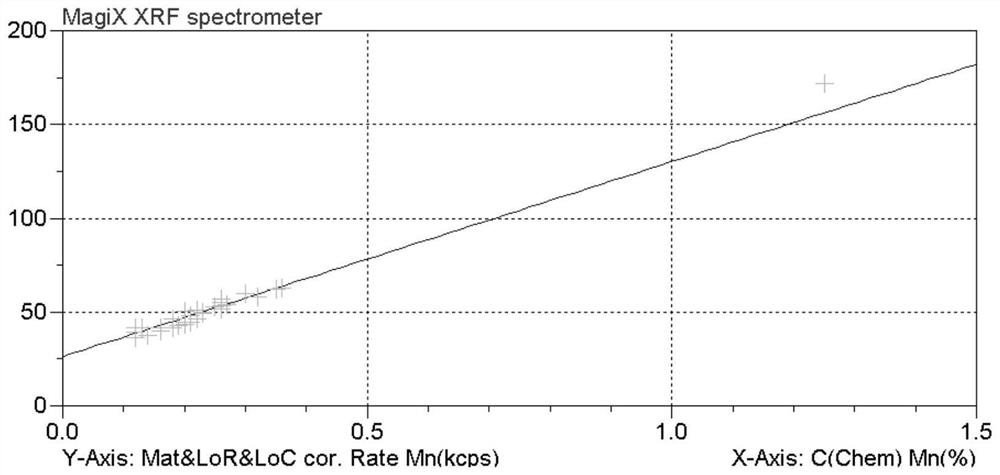

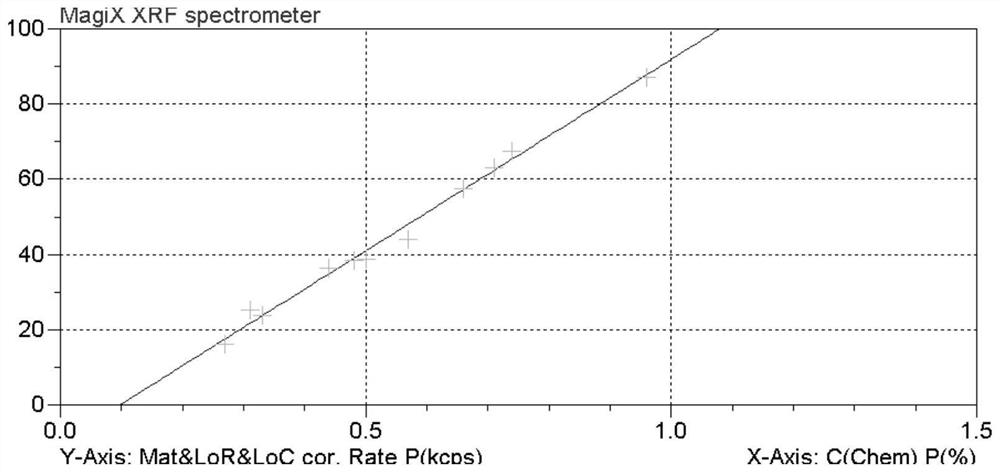

[0027] 1) The standard sample is determined by chemical method, and each standard sample with chemical legal value is made into a standard sample sheet for X-ray fluorescence spectrometer analysis by tablet method, and the chemical method value is used as the standard value to establish a standard curve;

[0028] 2) Scan one or several of the above-mentioned standard samples with an X-ray fluorescence spectrometer to establish basic analysis conditions;

[0029] 3) In the range of the standard curve, the content of each element Si is 11.08-18.73%, Mn is 0.12-0.42%, and P is 0.22-0.96%. For ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com