Real-time visual inspection method and system for high-speed penicillin bottle capping production line

A technology of real-time vision and detection methods, applied in the direction of neural learning methods, measurement devices, biological neural network models, etc., can solve the algorithm operation time requirements, increase the algorithm time complexity, and it is difficult to apply real-time detection on the high-speed capping production line of vials, etc. problem, to achieve the effect of facilitating adjustment and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

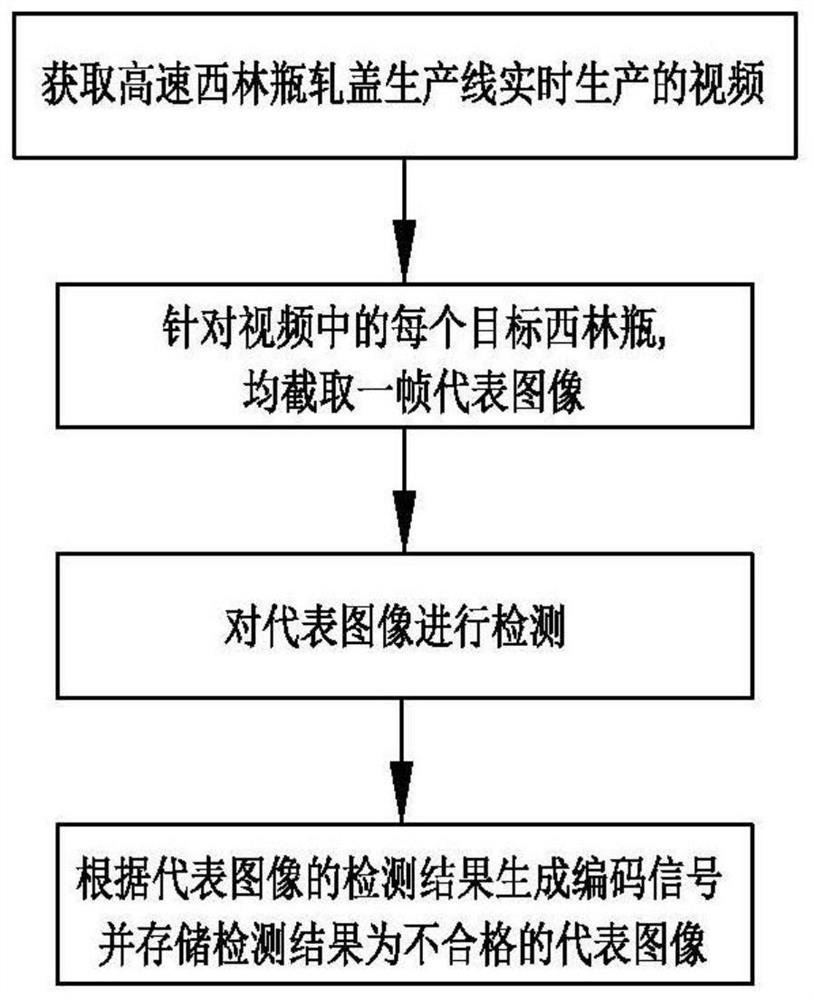

[0054] refer to Figure 1-6 , a real-time visual inspection method for a high-speed vial capping production line, including:

[0055] Obtain the real-time production video of the high-speed vial crimping and capping production line;

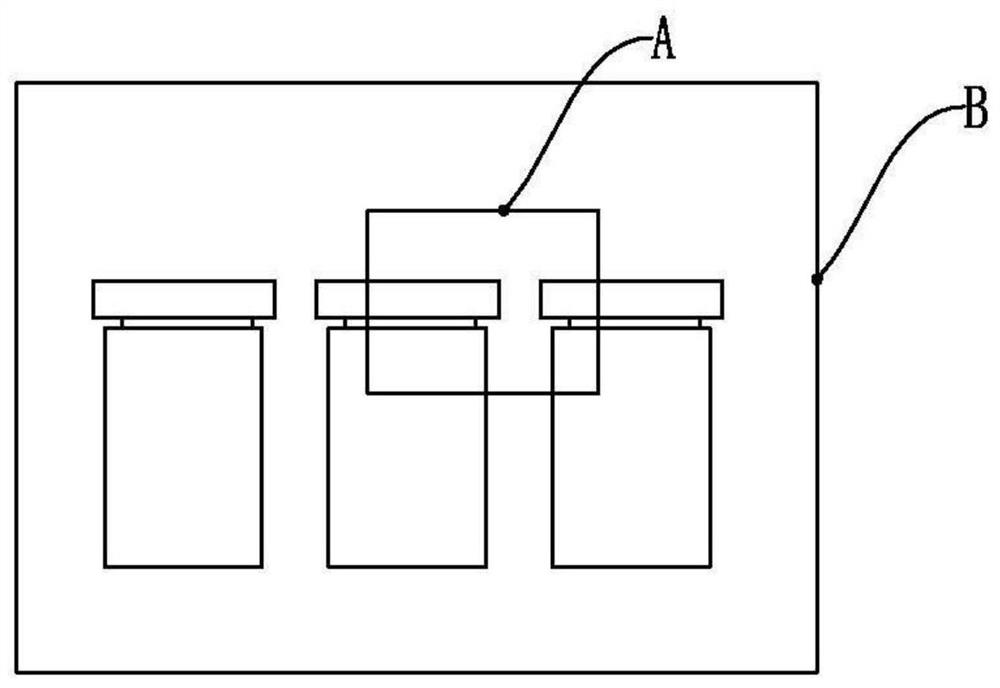

[0056] For each target vial in the video, a frame representative image is intercepted;

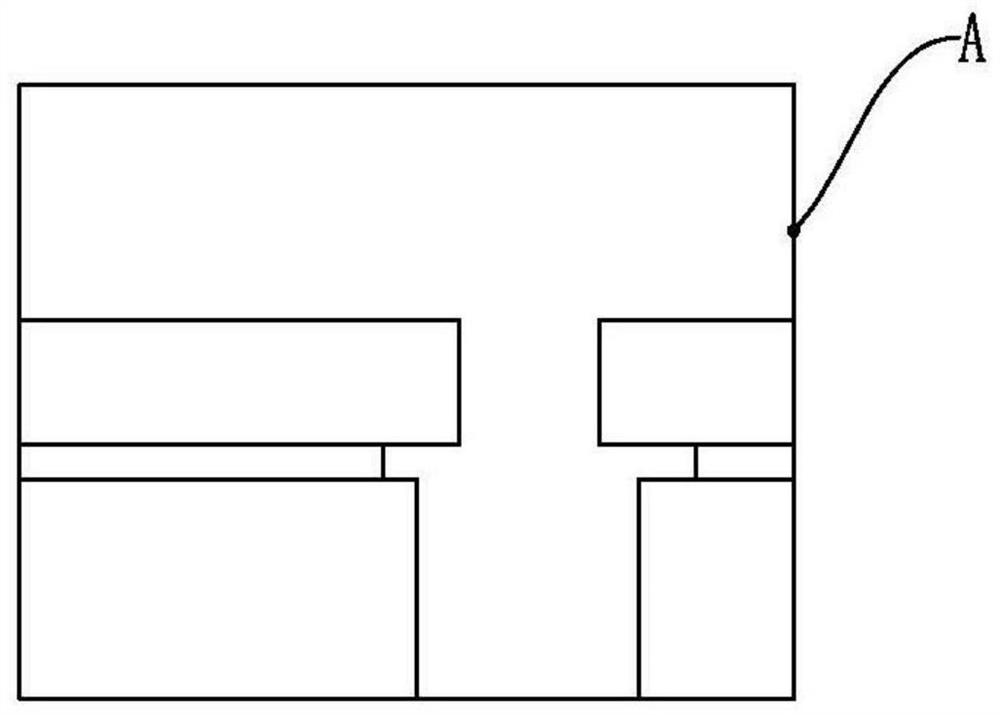

[0057] The target detection technology of deep learning is applied, and the size of the gap of the rubber stopper of the target vial is used as the detection target to detect the representative image; wherein, the target detection technology of deep learning can be a deep convolutional neural network. Object detection technology. Because the size of the gap of the vial rubber stopper is the most direct cause of whether the sealing of the vial is qualified or not, in an embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com