A Resonator-Based Etching Endpoint Detection System and Method

An endpoint detection and resonator technology, which is applied in the process, coating, and microstructure devices for producing decorative surface effects, can solve the problems of not considering the influence of the etching rate of the etching pattern, and not having universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

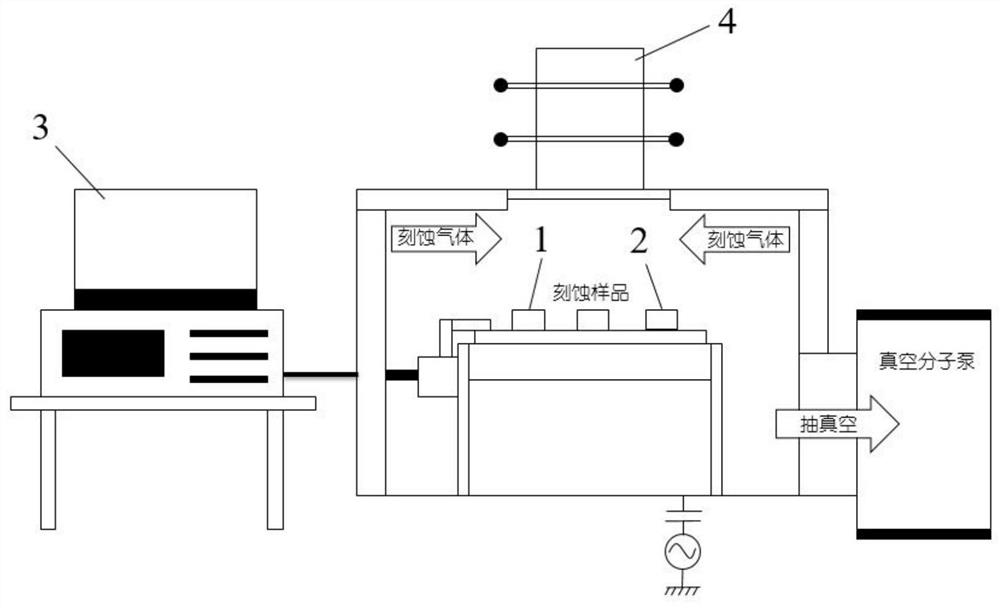

[0025] refer to figure 1 , a resonator-based etching endpoint detection system, including a coupled beam resonator 1 and a temperature compensation sensor 2, the coupled beam resonator 1 and the temperature compensation sensor 2 are simultaneously placed in the etching chamber of an etching machine 4, The etching signal data acquisition of the coupled beam resonator 1 and the temperature compensation sensor 2 are respectively completed through a closed-loop oscillator circuit, and the two closed-loop oscillator circuits send the etching signal data to the host computer 3 for data processing, and the host computer 3 performs data processing. Graphical display, the etching signal data of the upper computer 3 and the etching machine 4 are shared, which is convenient for effective control of the etching process.

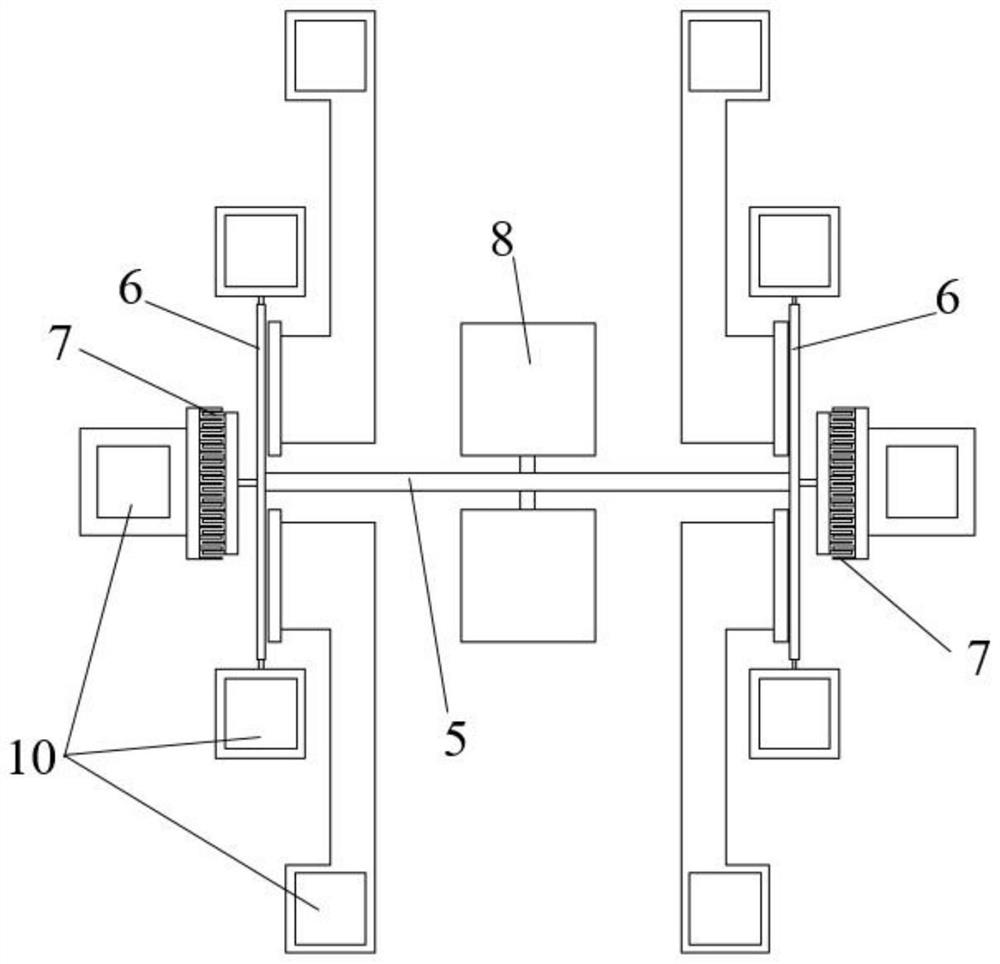

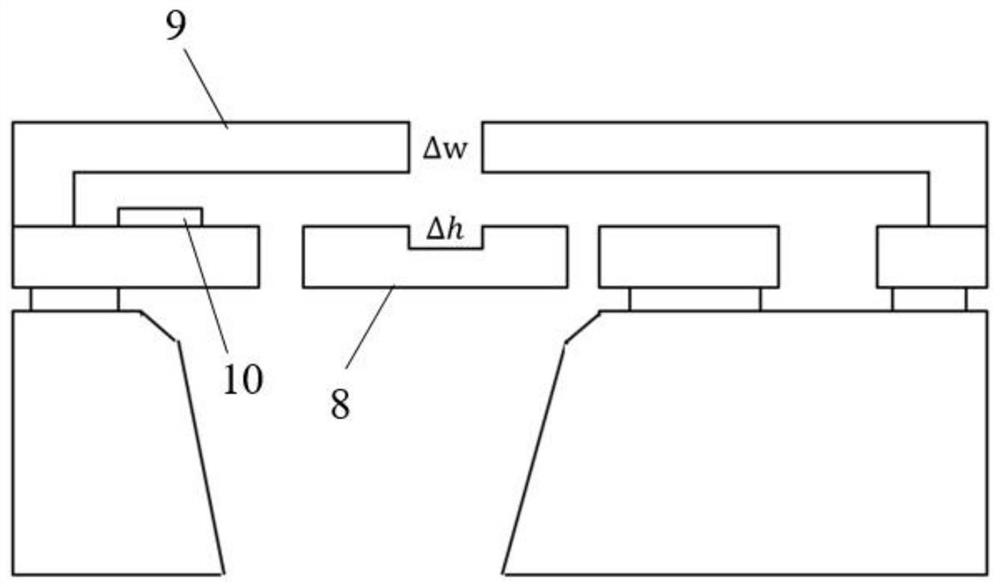

[0026] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com