Garbage recovery device for environment-friendly municipal administration path bridge engineering and treatment method

A municipal road and bridge engineering technology, applied in heating devices, grain processing, manufacturing tools, etc., can solve the problem that waste garbage cannot be recycled reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

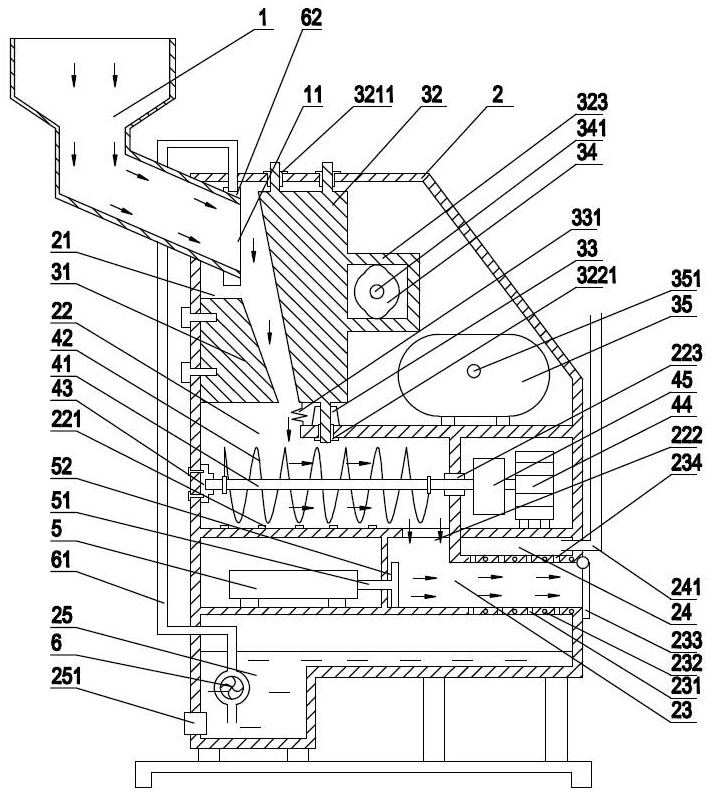

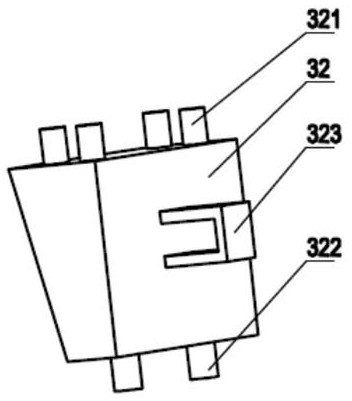

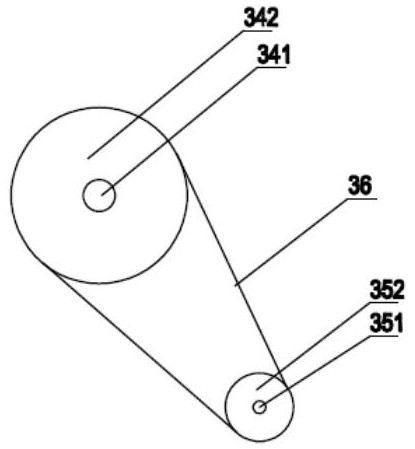

[0028] Such as Figure 1 to Figure 4 As shown, the environmentally-friendly municipal road and bridge engineering monitoring garbage recovery device according to the first embodiment includes a feeding hopper 1 and a hood 2. The feeding hopper 1 is connected to the upper left side of the hood 2, so The hood 2 is provided with a crushing zone 21, a grinding zone 22, a compression zone 23 and a water storage zone 25 in sequence from top to bottom. The middle part of the hood 2 is fixedly connected with a horizontal partition and a vertical partition. The crushing zone 21 is provided with a left crusher 31, a right crusher 32, a positioning rubber block 33, a dust-proof rubber cover 331, a driving cam 34 and a crushing motor 35, and the left crusher 31 is fixedly connected to the The upper part of the left side wall of the hood 2 is located below the feeding funnel 1, the upper part of the right crusher 32 is provided with multiple sets of sliding columns 321, the lower part is pr...

Embodiment 2

[0043] According to the treatment method of the environment-friendly municipal road and bridge engineering supervision garbage recovery device of the second embodiment, applying the environment-friendly municipal road and bridge engineering supervision garbage recovery device, the treatment method includes the following steps:

[0044] Put the material from the feed hopper 1, the water pump 6 sucks water from the water storage area 25, and sprays the material at the discharge port 11 through the water spray ring 62 to humidify the material; the material flows into the left crusher after being humidified Between 31 and the right crusher 32, under the action of the crushing motor 35, the driving small wheel 352 is transmitted to the large driving wheel 342 through the transmission belt 36, driving the wheel shaft 341 to rotate, and then driving the right pressure through the driving cam 34 The crusher 32 moves up and down. When the right crusher 32 moves up, the gap between the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com