Assembly type wave edge-shaped aerated concrete wallboard and manufacturing process

A technology of aerated concrete and manufacturing process, used in manufacturing tools, ceramic molding machines, building structures, etc., can solve the problems of limitation, large interface sliding deformation, low resistance to horizontal force, etc., and achieve high rigidity and seismic performance. Good, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A manufacturing process of an assembled corrugated edge type aerated concrete wall panel, characterized in that:

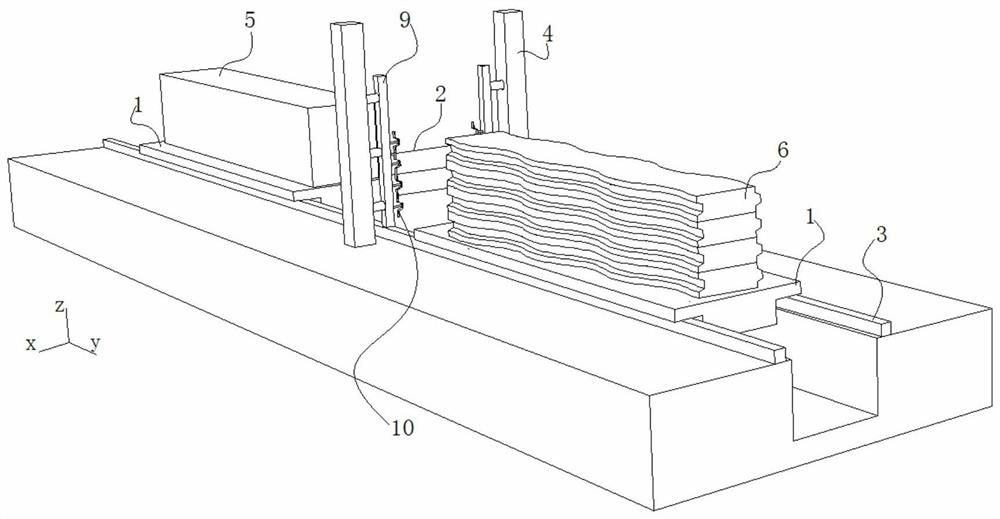

[0032] The preparation of the air-entrained concrete body 5 is as follows: the aerated concrete raw materials are mixed and stirred with water, and the plate steel bars are set in the mould. The fluid slurry is injected into the mold for curing, and after the green body is initially set, it is hoisted to the carrying platform of the carrier device 1 . Below the carrier 1 is a track 3 parallel to the x-axis.

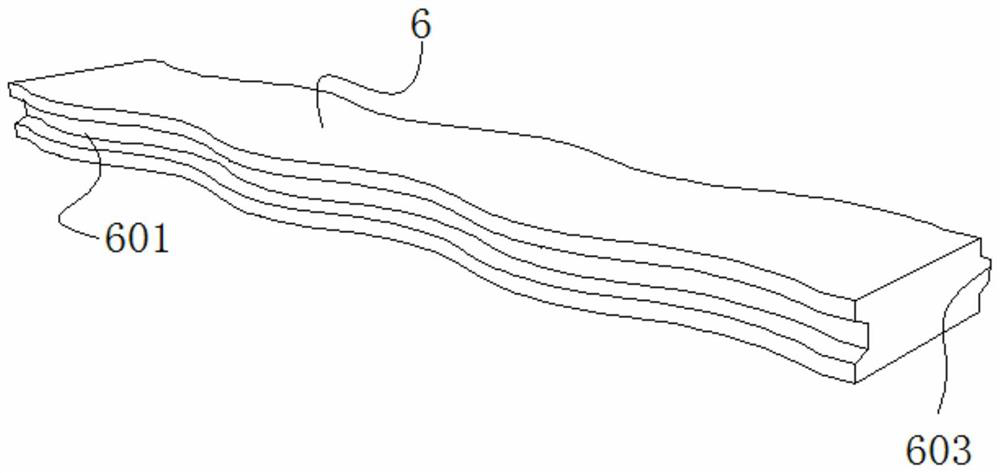

[0033] The manufacturing platform mainly includes a carrier device 1 and a cutting system. The aerated concrete body 5 is placed on the carrier 1 and moves at a constant speed along the horizontal y-axis. After passing through the cutting system, it is cut into several layers of prefabricated wall panels 6 .

[0034] On the path that the air-entrained concrete body 5 passes, the cutting system has several cutting lines 2 parallel to the horizontal x-...

Embodiment 2

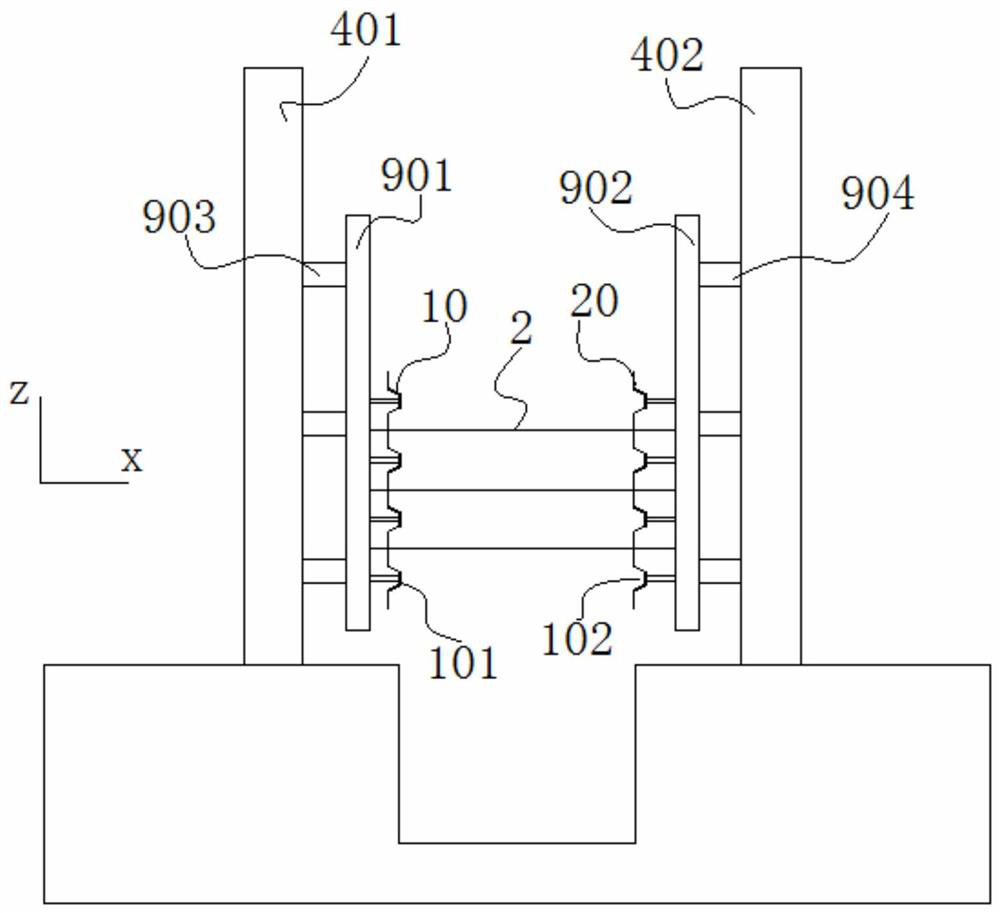

[0038] see figure 1 , The main structure of the manufacturing platform used in this embodiment is the same as that in Embodiment 1. Further, the cutting system mainly includes a cutting line 2, a frame 4, a telescopic support arm 9, a cutting tool I10, and a cutting tool II20.

[0039] The cutting line 2 cuts out two flat panel surfaces of the prefabricated wall panel 6 , and the cutting tool I10 and the cutting tool II20 cut out the wavy splicing surfaces on both sides of the prefabricated wall panel 6 .

[0040] The frame 4 includes a column I401 and a column II402 respectively located on two sides of the track 3 .

[0041] The air-entrained concrete body 5 is cut and processed between the column I401 and the column II402.

[0042] The telescopic support arm 9 includes a telescopic knife rest I901 installed on the side of the column I401 facing the column II402, and a telescopic knife rest II902 installed on the side of the column II402 facing the column I401. The telesco...

Embodiment 3

[0047] see figure 1 , The main structure of the manufacturing platform used in this embodiment is the same as in Embodiment 2. Further, the number of cutting lines 2 is three, and the aerated concrete body 5 can be cut into four prefabricated wall panels 6 stacked on top and bottom. The cutting line 2 is located between the cutting tool I10 and the cutting tool II20, and its two ends pass through the through holes on the cutting tool I10 and the cutting tool II20 respectively, and are connected to the telescopic knife rest I901 and the telescopic knife rest II902 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com