Multi-variety material mixed packaging production line and control method

A packaging production line and material mixing technology, applied in the direction of packaging automatic control, packaging, packaging machines, etc., can solve the problems that affect the efficiency of the production line and low degree of automation, and achieve the effect of saving manpower and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

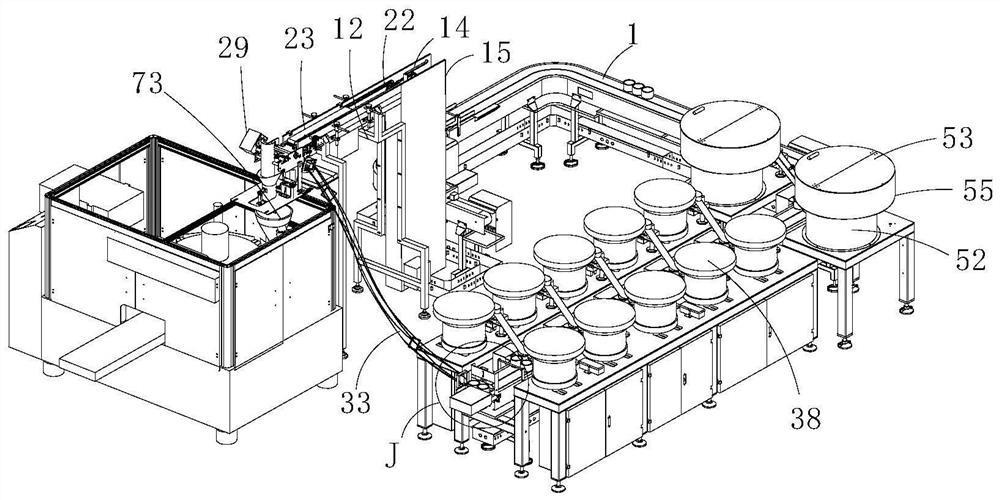

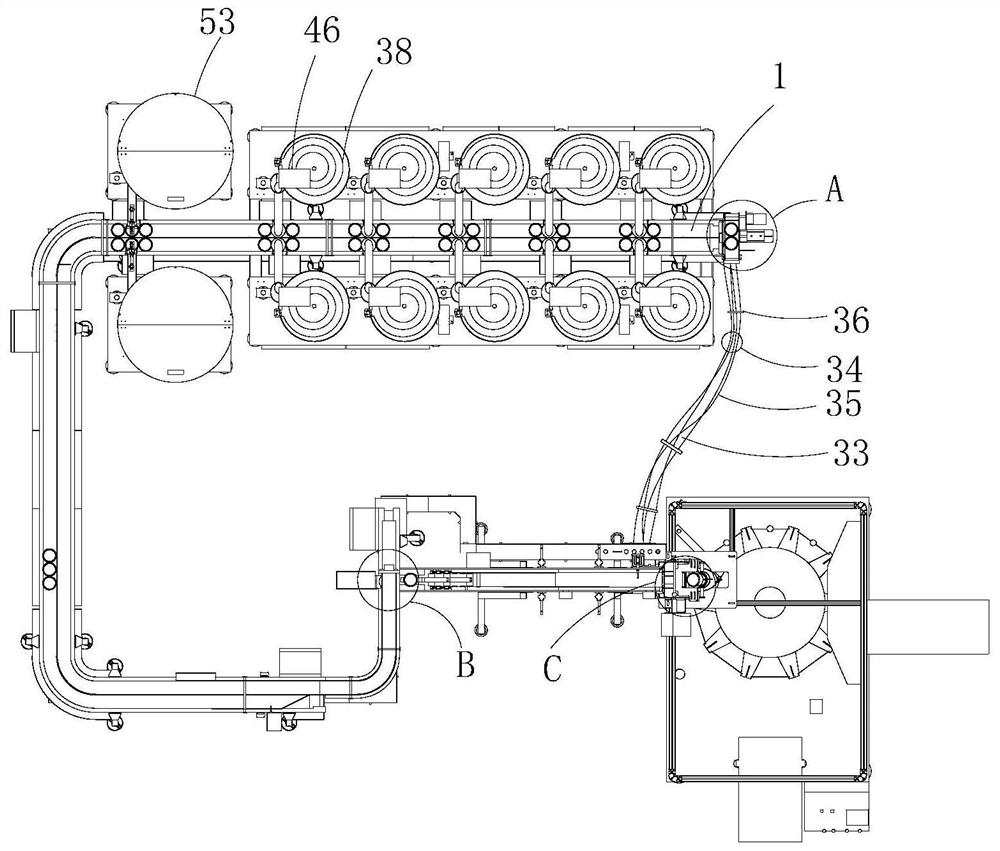

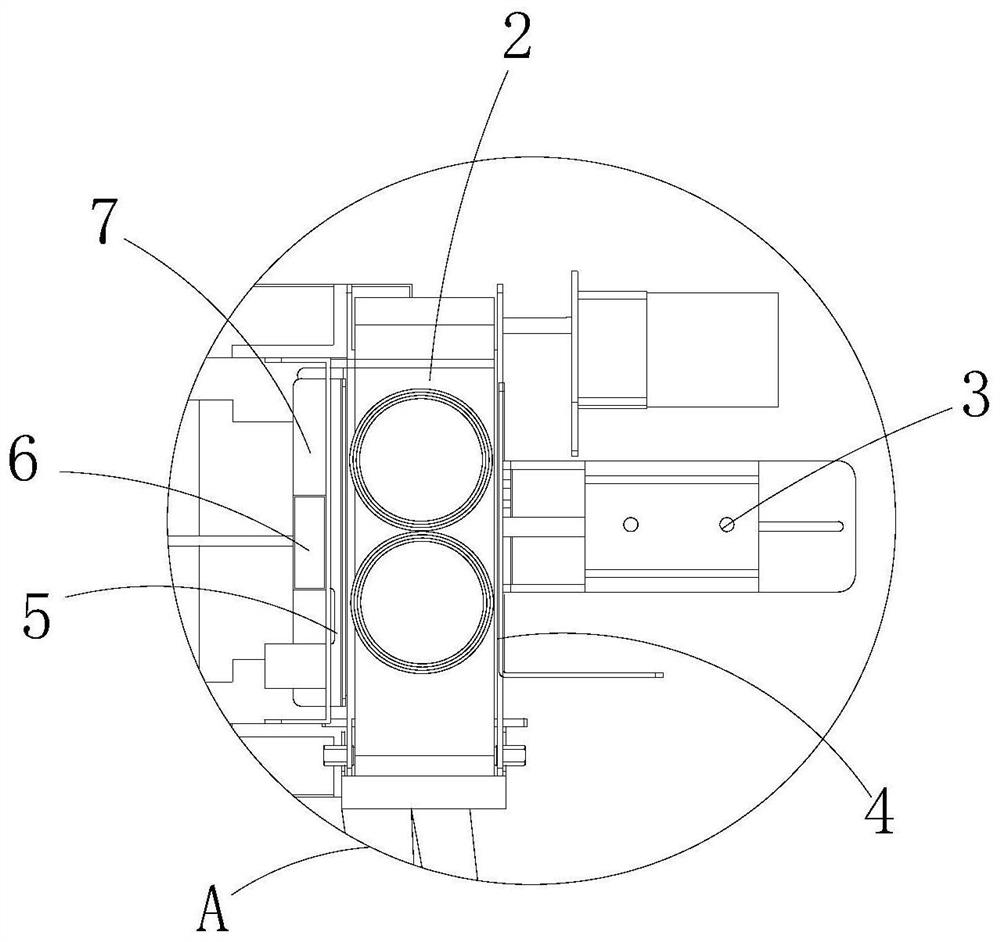

[0074] Take for example a nut mix that includes almonds, hazelnut kernels, dried blueberries, raisins and walnut kernels, dried cranberries, and cashew kernels. Other mixes work similarly, such as figure 1 As shown, a multi-variety material mixed packaging production line includes a control unit, a feeding unit, a transport unit, a recycling unit, and a packaging unit. The control unit is electrically connected to the feeding unit, the transport unit, and the packaging unit. Above, the inlet of the transport unit is connected to the outlet of the recovery unit, and the outlet of the transport unit is connected to the inlets of the packaging unit and the recovery unit respectively. Wherein, the controller in the control unit is a PLC controller, and conventional supporting equipment in the prior art such as a power supply, a sensor, a solenoid valve group and an actuator used in conjunction with the PLC controller. The packaging unit includes a bag taking mechanism, a clamp, a ...

Embodiment 2

[0097] Such as Figure 15 As shown, the structure of this embodiment is basically the same as that of the first embodiment, the difference is that the spiral channel 33 is a side closed channel, and the inner side walls of the spiral channel 33 are provided with first arc-shaped protrusions 67 for reducing The contact area between the material and the spiral passage 33, the number of the first arc-shaped protrusions 67 is multiple, and the extension direction of each first arc-shaped protrusion 67 is consistent with the extension direction of the spiral passage 33. At this time, the spiral passage 33 It is a square tube twisted 180° closed around the opening at both ends, which can reduce the contact between the material bowl and the external environment of the spiral channel 33 during the movement of the material bowl, and prevent the material bowl from being polluted.

Embodiment 3

[0099] Such as Figure 26-Figure 27 As shown, the structure of this embodiment is basically the same as that of other embodiments, the difference is that both sides of the material guide pipe 25 are fixedly connected with the first support frame 83 through the connecting rod 68, and the bottom of the material guide pipe 25 is provided with a material guide hopper 69 , the guide hopper 69 is fixedly installed on the first support frame 83, and can collect the food material falling in the guide pipe 25 and pass it downward. The bottom surface of the guide bowl groove 27 is provided with several ash leakage holes 80 . The bottom of the bowl guide groove 27 is provided with a placement frame 70, and the placement frame 70 is provided with an ash tray 71. To collect the peel debris poured out of the material bowl on the bowl guide groove 27, so when the bowl turning mechanism places the mouth of the bowl downward, it also has the purpose of dumping the fruit peel debris in the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com