Low-density plugging cement paste system for well cementation of fractured reservoirs

A low-density, oil-reservoir technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem that the strength of the cement stone cement sheath is not enough to effectively seal the oil-water layer, destroy the stability of the cement slurry system, and fail to achieve Seal formation water, protect casing and other problems, achieve excellent compressive strength and long-term mechanical properties, improve long-term sealing integrity, and prevent oil, gas and water channeling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

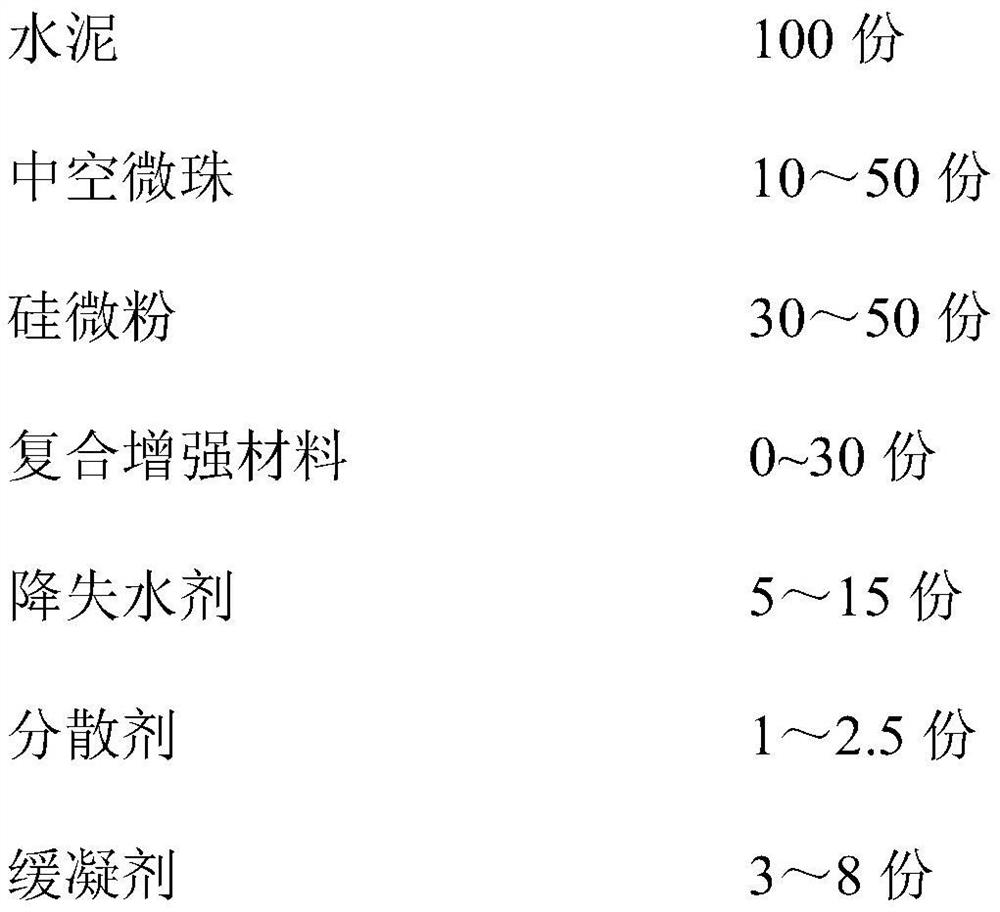

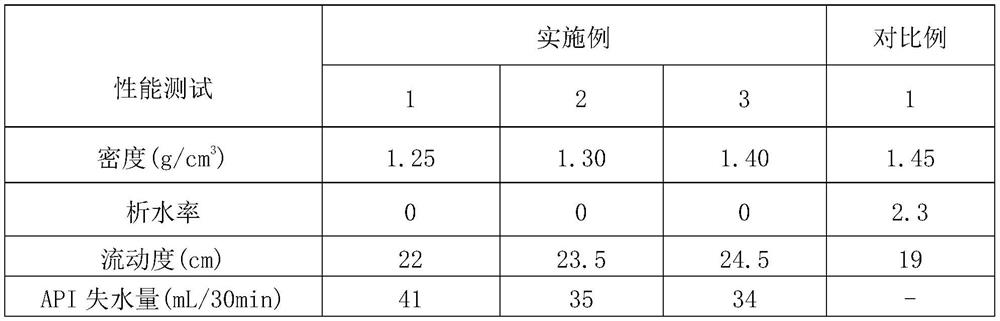

Embodiment 1

[0023] 100 parts of cement, 50 parts of hollow microspheres, 40 parts of silica powder, 25 parts of composite reinforcing materials, 5 parts of fluid loss reducer, 1.5 parts of dispersant, 5 parts of retarder, 2.5 parts of fiber, and 100 parts of water. The experimental results are shown in Table 1.

Embodiment 2

[0025] 100 parts of cement, 40 parts of hollow microspheres, 40 parts of silica powder, 25 parts of composite reinforcing materials, 5 parts of fluid loss reducer, 1.5 parts of dispersant, 5 parts of retarder, 2.5 parts of fiber, and 100 parts of water. The experimental results are shown in Table 1.

Embodiment 3

[0027] 100 parts of cement, 30 parts of hollow microspheres, 40 parts of silica powder, 25 parts of composite reinforcing materials, 5 parts of fluid loss reducer, 1.5 parts of dispersant, 5 parts of retarder, 2.5 parts of fiber, and 100 parts of water. The experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com