Bolt processing system

A processing system and bolt technology, applied in metal processing equipment, manufacturing tools, furnace types, etc., can solve the problem of heavy workload of operators, and achieve the effect of reducing workload, improving processing efficiency, and increasing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

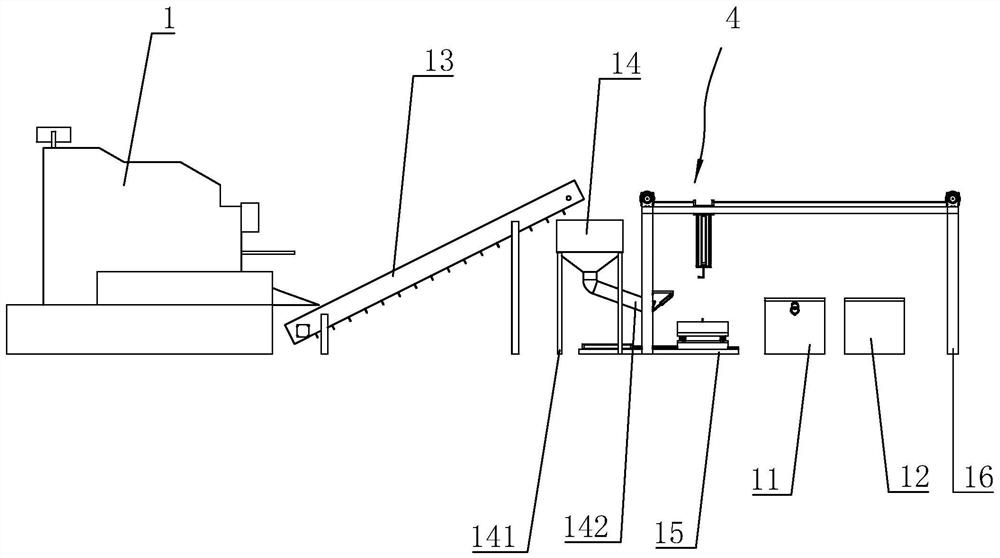

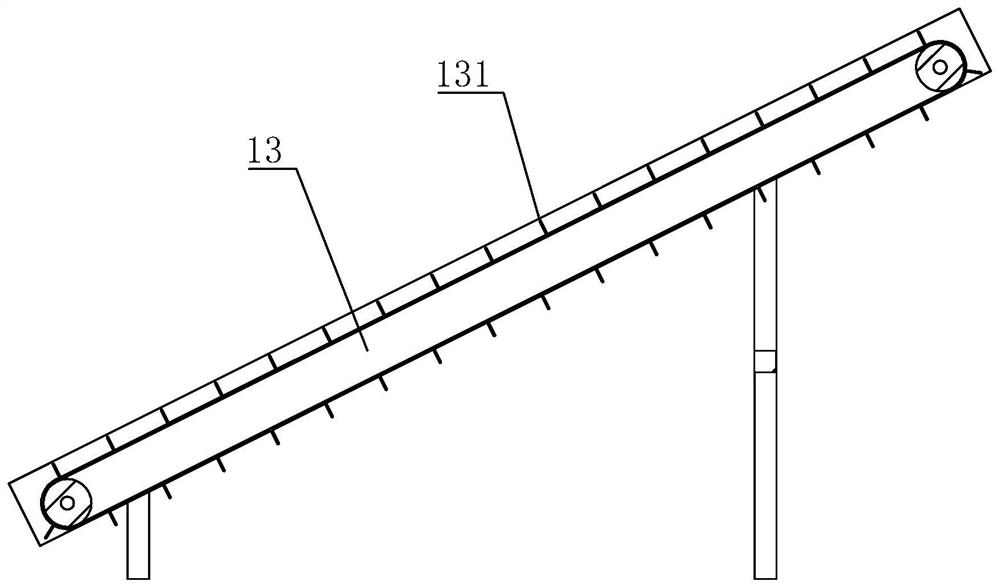

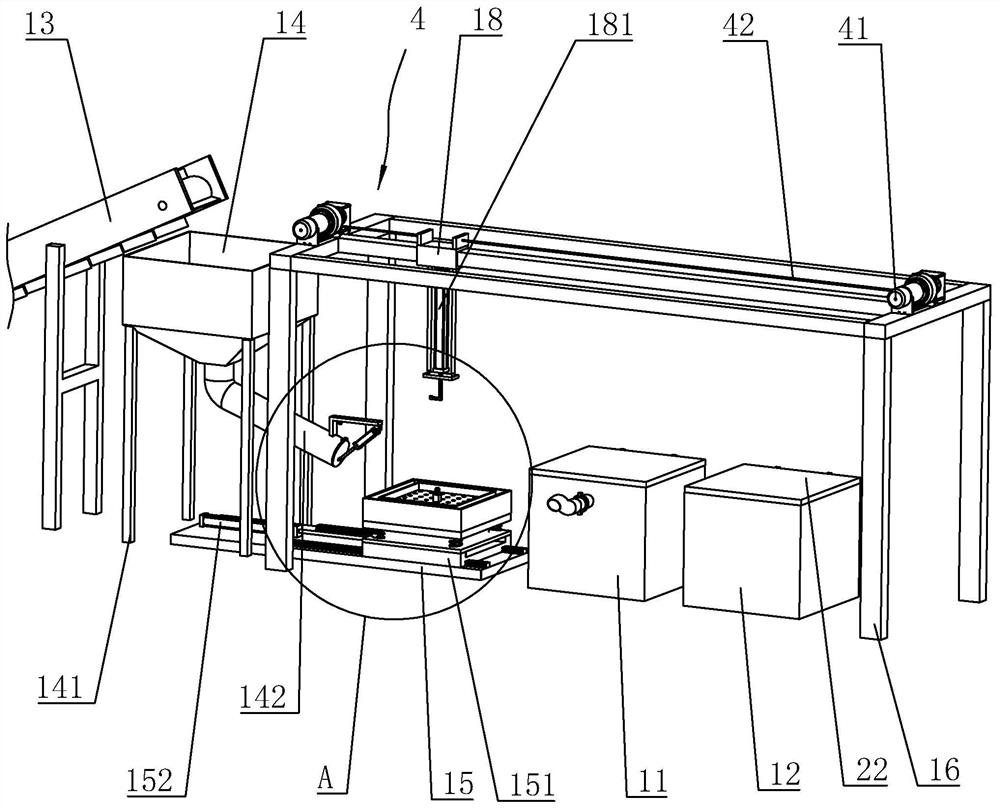

[0040] like figure 1 and figure 2 As shown, it is a bolt processing system disclosed in the present invention, including a cold heading machine 1, a quenching furnace 11, a tempering furnace 12, a hoist 13, a storage box 14, a bracket 15 and a base frame 16, and the input of the hoist 13 The end is located at the discharge port of the cold forging machine, and the bolts falling on the belt of the hoist 13 are transmitted upwards. The output end of the hoist 13 is located above the feed inlet of the storage box 14. The belt of the hoist 13 is provided with several The material plates 131 are equidistantly distributed along its outer contour, so as to reduce the drop of bolts during transmission.

[0041] like image 3 and Figure 4As shown, the material storage box 14 is lifted off the ground by a support frame 141. The bottom of the material storage box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com