Building formwork quick-release supporting system

A technology of building formwork and support system, which is applied in the direction of building, building structure, formwork/formwork/work frame, etc., can solve the problems of insufficient structural strength, complex connection relationship, large weight increase, etc., to achieve accurate size and high efficiency , Easy installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

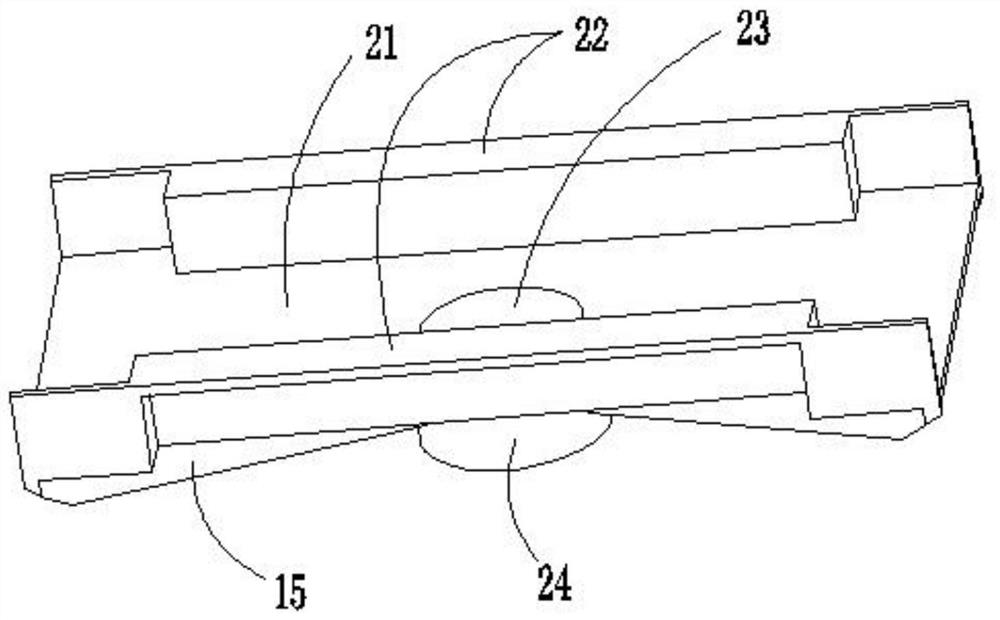

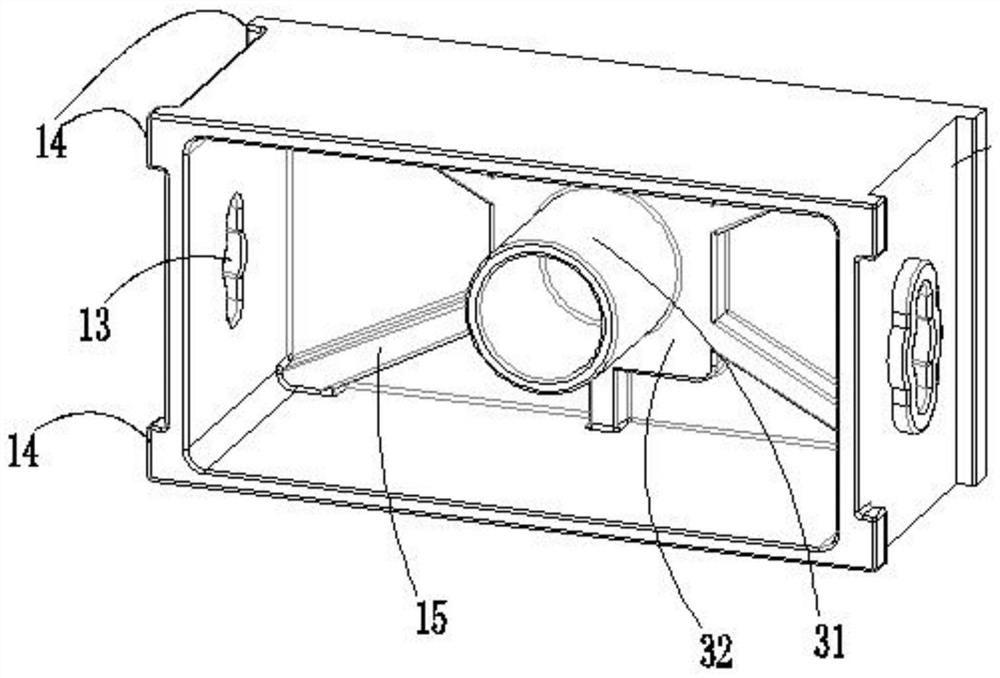

[0065] The present invention proposes a quick-release support system for building formwork, which includes several formwork members. 1 The bottom is fixed on the ground, the support head assembly is adjustable and installed on the top of the support rod assembly 1, the keel 4 is erected between the adjacent support head assemblies, and the flat plate 8 is tightly laid between the adjacent keel 4 , by laying a plurality of flat plates 8 into a closed support plane, the corner connectors are arranged at the intersection of the keel 4 or the flat plates 8 and the wall or beams for transfer, and the fasteners are arranged at the joints of other different components Locking and fixing are realized, thereby forming a complete building formwork, and the materials of all formwork components except the support rod assembly 1 are polymer composite plastics.

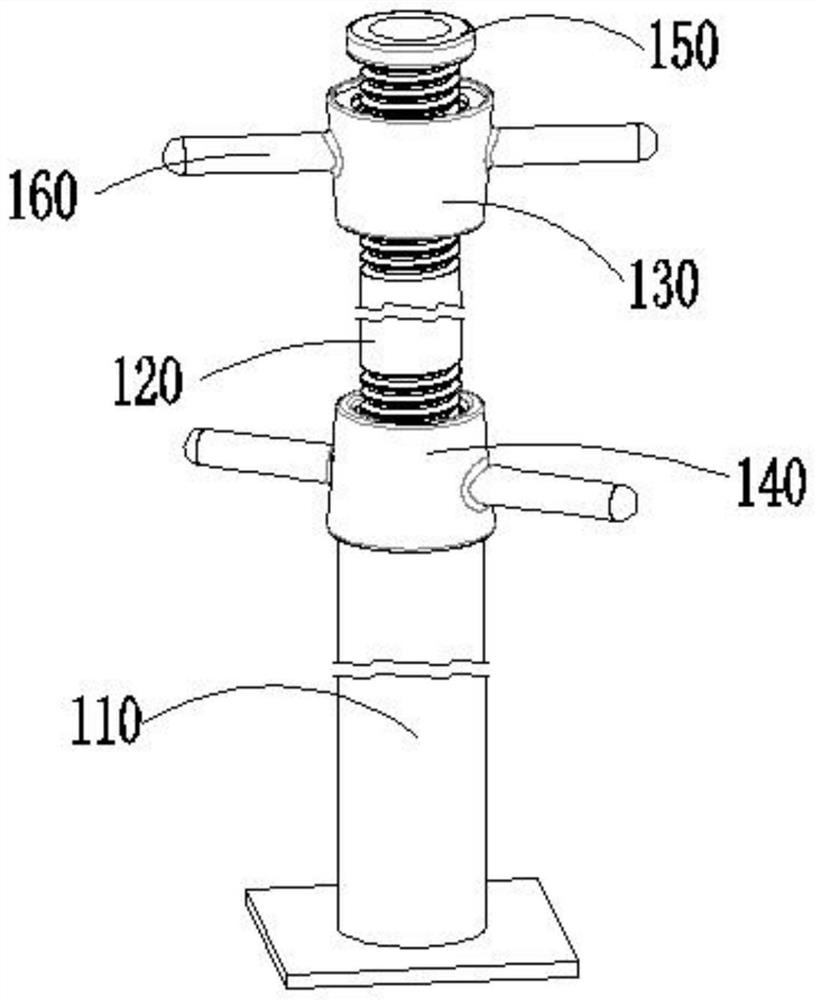

[0066] like figure 1 As shown, in the present invention, the support rod assembly 1 includes a hollow fixed rod 110 and a movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com