Retired power battery performance evaluation method and system

A power battery and battery technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve problems such as reducing the economical efficiency of power battery cascade utilization, destroying the performance of retired power batteries, etc. Performance evaluation time, evaluation cost savings, easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

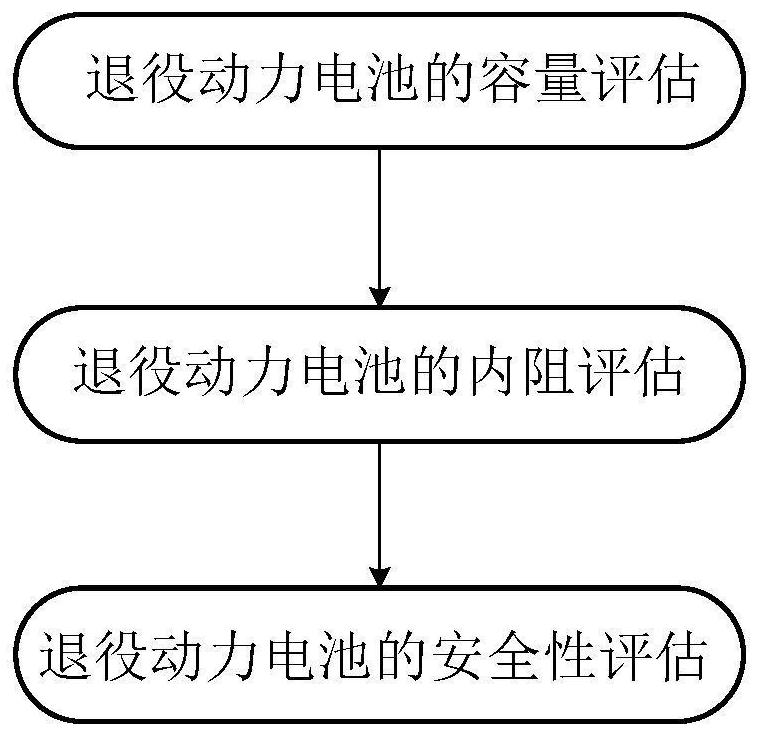

[0046] This embodiment provides a method for evaluating the performance of decommissioned power batteries, such as figure 1 As shown, the steps are as follows:

[0047] (1) Capacity evaluation of decommissioned power batteries: Estimate the remaining capacity of decommissioned power batteries according to the voltage change of the decommissioned power batteries during the charging and discharging process of 5-10 minutes.

[0048] ①Measure the open circuit voltage V of the battery ocv , and judge whether the battery is charging or discharging according to the open circuit voltage value. For lithium iron phosphate / graphite system batteries, when the open circuit voltage is less than 3.23V, charge it; when the open circuit voltage is greater than 3.28V, discharge it; when the open circuit voltage is between 3.23-3.28V, charge it It can be charged or discharged.

[0049] ②Charge (or discharge) the battery at a rate of 1 / 3C of the rated capacity of this type of battery for 5-10 ...

Embodiment 2

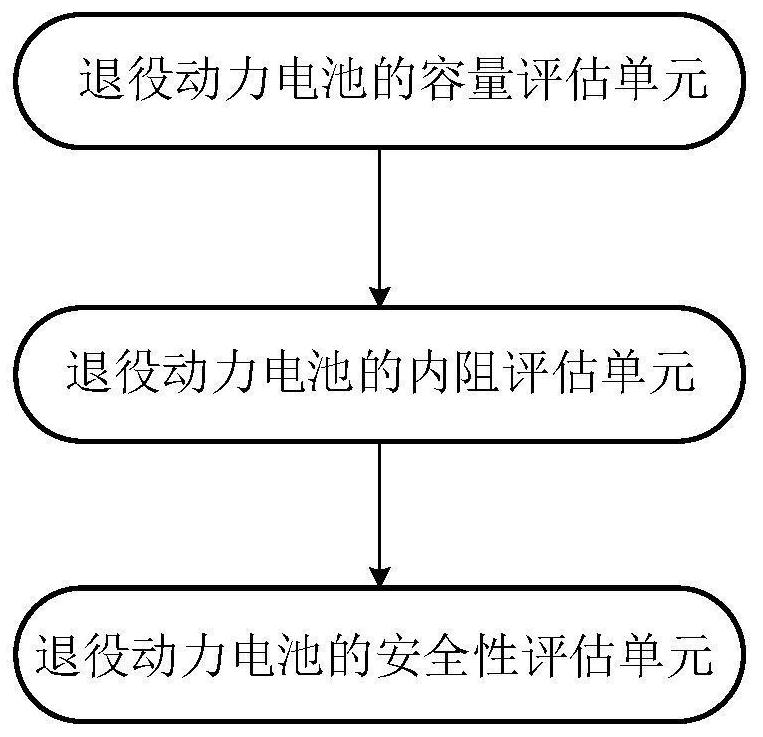

[0070] This embodiment provides a decommissioned power battery performance evaluation system, such as figure 2 As shown, it is composed of the capacity evaluation unit of the retired power battery, the internal resistance evaluation unit of the retired power battery and the safety evaluation unit of the retired power battery.

[0071] 1. The capacity evaluation unit of the decommissioned power battery: Estimate the remaining capacity of the decommissioned power battery according to the voltage change of the decommissioned power battery during the charging and discharging process of 5-10 minutes. The specific evaluation process of capacity is as follows:

[0072] ①Measure the open circuit voltage V of the battery ocv , and judge whether the battery is charging or discharging according to the open circuit voltage value. For lithium iron phosphate / graphite system batteries, when the open circuit voltage is less than 3.23V, charge it; when the open circuit voltage is greater th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com